Flanges are critical components in piping systems, and their durability is essential for maintaining operational safety and reliability. JC, a leading Investment Casting & machining manufacturer, leverages advanced Stainless Steel Casting methods to significantly enhance flange durability. Investment casting (lost-wax process) with high-grade stainless steel alloys such as 304, 316, and duplex stainless steel offers superior corrosion resistance, mechanical strength, and precision. These properties are crucial for flanges used in challenging environments like oil & gas, chemical plants, and water treatment facilities.

JC’s manufacturing process includes meticulous material selection, precise casting, and high-accuracy CNC machining, ensuring optimal surface finish, dimensional accuracy, and long-lasting performance. Rigorous quality control, including non-destructive testing and full traceability, guarantees the reliability of every flange. JC also emphasizes customization, sustainability, and compliance with international standards, setting benchmarks in flange durability.

The article highlights JC’s commitment to innovation, with ongoing R&D in new alloys, smart manufacturing, and global collaborations. Case studies demonstrate JC’s proven track record in delivering flanges that outperform traditional forged components in terms of lifespan and maintenance costs.

For businesses seeking durable, reliable, and customized flange solutions, JC offers comprehensive end-to-end services backed by decades of expertise, advanced technology, and a dedication to quality and environmental responsibility.

Flanges play a crucial role in the piping systems across industries, serving as the essential connectors between pipes, valves, pumps, and other equipment. Their durability, reliability, and lifespan are of paramount concern, especially in demanding environments such as oil & gas, chemical processing, power generation, and water treatment. JC, as a renowned Investment Casting & machining manufacturer, is at the forefront of employing advanced stainless steel casting techniques to enhance the durability of flanges, delivering products that meet and exceed industry standards.

Understanding Flanges and Their Application

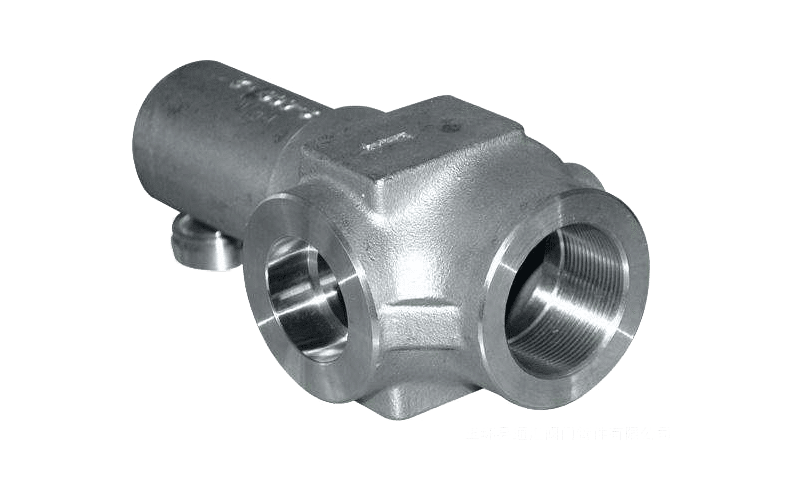

Flanges are mechanical devices designed to join two or more components, facilitating easy assembly, disassembly, and maintenance in piping networks. They come in various types, such as weld neck, slip-on, blind, socket weld, and threaded, each offering unique features suited to specific operational requirements. The choice of material and manufacturing process directly influences the durability, corrosion resistance, and mechanical properties of flanges.

Challenges Affecting Flange Durability

Flanges often operate under harsh conditions involving high pressure, temperature fluctuations, corrosive fluids, and mechanical stresses. Common challenges include:

- Corrosion: Exposure to chemicals and moisture promotes rusting and degradation.

- Mechanical Wear: Constant vibration, pressure cycles, and thermal expansion cause fatigue and surface wear.

- Structural Integrity: Poor casting or inadequate material selection leads to cracks, leaks, and failures.

- Dimensional Inaccuracies: Improper machining and casting methods yield out-of-tolerance components, affecting fit and sealing.

Stainless Steel Casting: A Game Changer for Flanges

JC utilizes precision investment casting with stainless steel alloys to manufacture high-durability flanges. Investment casting, also known as lost-wax casting, offers unparalleled control over part geometry, surface finish, and metallurgical properties. Stainless steel, with its inherent corrosion resistance, strength, and ductility, is the preferred material for critical flange applications.

undefined

Advantages of Stainless Steel Investment Casting Over Conventional Methods

- Superior Corrosion Resistance: Stainless steel alloys, like 304, 316, and duplex grades, provide lasting protection against acids, alkalis, and saline environments, drastically increasing flange lifespan.

- Enhanced Mechanical Properties: Investment casting allows for uniform grain structure and precise chemical composition, resulting in high tensile and yield strength.

- Complex Geometries: The flexibility of the lost-wax process enables JC to produce flanges with intricate designs, optimized for flow, sealing, and assembly.

- Exceptional Surface Finish: Cast flanges have smoother surfaces, reducing the risk of stress concentration and crack initiation.

- Dimensional Accuracy: JC’s investment casting achieves tight tolerances, ensuring perfect fit and optimal gasket sealing, critical for leak prevention.

JC’s Manufacturing Excellence: Process Overview

Material Selection

At JC, the selection of stainless steel grades is dictated by the operational environment and customer requirements. Commonly used grades in flange casting include:

- 304 Stainless Steel: Suitable for general-purpose applications with moderate corrosion exposure.

- 316 Stainless Steel: Preferred for marine and chemical industries due to superior pitting resistance.

- Duplex Stainless Steel: Offers exceptional strength and resistance to stress corrosion cracking.

Investment Casting Process Steps

- Wax Pattern Creation: High-precision wax models are crafted to replicate the flange design.

- Shell Building: Multiple ceramic layers are applied to the wax pattern, forming a robust shell.

- Wax Removal: The assembly is heated, melting the wax and leaving a cavity for metal pouring.

- Metal Pouring: Molten stainless steel is introduced, filling the shell and taking its shape.

- Final Finishing & Machining: After shell removal, JC’s expert machinists perform CNC machining, drilling, and inspection, guaranteeing precision.

Quality Control and Testing at JC

Comprehensive Inspection Protocols

JC’s commitment to quality is reflected in its rigorous inspection processes. Each flange undergoes:

- Non-Destructive Testing (NDT): Ultrasonic, magnetic particle, and dye penetrant testing to identify subsurface and surface defects.

- Dimensional Verification: Coordinate Measuring Machines (CMM) ensure every flange meets specified tolerances.

- Mechanical Testing: Tensile, hardness, and impact tests validate material performance under load.

- Corrosion Testing: Salt spray and immersion tests simulate operational environments.

Traceability and Documentation

Every JC flange is supplied with detailed material certificates, process records, and test reports, providing full traceability for critical installations.

Machining Enhancements for Flange Durability

While investment casting delivers near-net shapes, JC further enhances flange durability through precision CNC machining. Machining operations such as facing, drilling, tapping, and groove forming create sealing surfaces with micron-level flatness and smoothness, essential for reliable gasket seating and leak-proof assembly.

Benefits of Advanced Machining

- Improved Surface Integrity: Machining removes casting artifacts, minimizing stress risers and potential crack sites.

- Custom Features: JC offers bespoke machining options for bolt holes, keyways, and special profiles.

- Consistency: Automated CNC systems ensure repeatability across large production runs.

Innovation and Customization at JC

Tailored Flange Solutions

JC collaborates with clients to design and manufacture custom flanges that address unique operational challenges. Customization options include:

- Material grade selection based on fluid composition and temperature.

- Specialized surface treatments such as passivation and electropolishing.

- Unique geometries for high-pressure, high-temperature, or corrosive environments.

- Integration with valves, couplings, and instrumentation.

Research and Development

The R&D team at JC continually investigates new stainless steel alloys, casting techniques, and machining technologies to push the boundaries of flange durability. Innovations in low-carbon alloys, heat treatment processes, and smart inspection systems ensure JC flanges remain at the leading edge of performance and reliability.

Case Studies: JC Flanges in Action

Offshore Oil & Gas Platform

JC supplied duplex stainless steel flanges for an offshore platform, exposed to saltwater, fluctuating pressures, and mechanical loading. After five years, inspections revealed minimal corrosion and zero failures, demonstrating the efficacy of JC’s casting and machining approach.

Chemical Processing Plant

Flanges manufactured by JC using 316 stainless steel were installed in a plant handling aggressive acids. Enhanced corrosion resistance extended the service life threefold compared to conventional forged flanges.

Municipal Water Treatment

JC’s investment cast flanges, with electropolished surfaces, ensured leak-free connections and compliance with sanitary standards in a municipal water treatment facility.

Environmental and Economic Benefits

Sustainability in Manufacturing

JC’s investment casting process minimizes material waste, reduces energy consumption, and enables recycling of unused alloys. Longer-lasting flanges decrease the frequency of replacements, leading to lower resource consumption over the life cycle.

Cost Efficiency

- Lower Maintenance Costs: Durable JC flanges reduce downtime and repair costs.

- Fewer Replacements: Extended lifespan means fewer purchases over time.

- Operational Reliability: Enhanced performance avoids costly system failures and interruptions.

Industry Standards and Compliance

JC manufactures flanges in strict accordance with global standards such as ASME, ANSI, DIN, and ISO, ensuring compatibility, safety, and regulatory compliance in international projects.

Certifications

- ISO 9001: Quality management systems.

- PED: Pressure Equipment Directive for European applications.

- API: American Petroleum Institute standards for oil & gas.

- RoHS: Restriction of hazardous substances for environmental safety.

Why Choose JC for Stainless Steel Flange Solutions?

Expertise and Experience

JC brings decades of expertise as an Investment Casting & machining manufacturer, with a proven track record in delivering durable, high-performance flanges worldwide.

End-to-End Service

- Design consultation and engineering support.

- Material selection and alloy development.

- Advanced casting and machining capabilities.

- Stringent quality control and documentation.

- Logistics and after-sales support.

Future Trends in Flange Durability Enhancement

Smart Manufacturing

JC is investing in Industry 4.0 technologies such as IoT-enabled inspection, predictive maintenance algorithms, and AI-driven quality analysis to further improve flange durability and traceability.

New Materials and Coatings

Research into nano-structured stainless steel, advanced composite coatings, and surface engineering continues, aiming to create flanges with ultra-high corrosion and wear resistance.

Global Collaboration

JC partners with research institutions and industry leaders to share knowledge, develop new standards, and set benchmarks for flange durability worldwide.

Technical Comparison Table: Flange Manufacturing Methods

| Aspect | Traditional Forging | Investment Casting (JC) |

|---|---|---|

| Corrosion Resistance | Moderate | High (Stainless Steel) |

| Dimensional Accuracy | ±0.5 mm | ±0.1 mm |

| Surface Finish | Rough | Smooth |

| Complex Geometry | Limited | Advanced |

| Customization | Challenging | Flexible |

| Mechanical Strength | Good | Excellent |

| Lead Time | Long | Short |

| Quality Control | Manual | Automated |

FAQs: Stainless Steel Casting and Flange Durability

- How does investment casting improve flange durability?

It delivers precise geometry, superior surface finish, and homogeneous material properties, reducing the risk of failure. - Which stainless steel grade is best for flange casting?

Grade selection depends on the application; 316 and duplex grades offer top corrosion and mechanical resistance. - Can JC produce custom flange designs?

Yes, JC excels in bespoke engineering and manufacturing for specific client needs. - What quality standards do JC flanges meet?

JC complies with ASME, ANSI, API, DIN, and ISO standards. - Is investment casting environmentally friendly?

Yes, it minimizes waste and energy use compared to forging and subtractive manufacturing.

Contact JC for Your Flange Needs

If you are seeking enhanced durability, reliability, and custom engineering for your flange requirements, JC stands ready to deliver proven solutions with advanced stainless steel casting and machining. Contact JC’s expert team to discuss your project and experience best-in-class flange performance.

Tags:3d printing investment casting,water glass casting,Investment Casting Factory,cnc machining