What is the Investment Casting Tolerances?

Investment Casting Tolerances means the dimension range that can be met by investment casting. Its standard can be classified into 2 parts: Linear Tolerances and Geometric Tolerances.

| Geometric Tolerances | Linear Tolerances |

| Flatness | Flatness |

| Straightness | Straightness, Length |

| Parallelism | Corner Radii |

| Roundness | Flatness |

| Concentricity | Concentricity |

| Hole Tolerance | Holes |

| Curved Holes, Internal Radii, and Fillets | Curved Holes, Fillet radii |

Linear tolerance

Linear tolerancing is normally applied to the investment castings features of Length, Concentricity, Fillet radii, Holes, Straightness, Corner Radii, Flatness, and Curved Holes.

Each casting process’s linear tolerances are not the same. For example, the water glass lost wax casting can control general linear tolerances between CT7-CT8. The lost foam casting can meet CT8-CT9. But the silica sol casting tolerance is the most precise, it reaches CT5-CT6. Below is a list of liner tolerance standards for casting:

| ISO8062(GB/T6414) CT4-CT8—Norminal dimension (mm) Linear dimension tolerance (ISO8062) |

| > | ≤ | CT4 | CT5 | CT6 | CT7 | CT8 | |||||

| 0 | 10 | 0.26 | ±0.13 | 0.36 | ±0.18 | 0.52 | ±0.26 | 0.74 | ±0.37 | 1 | ±0.5 |

| 10 | 16 | 0.28 | ±0.14 | 0.38 | ±0.19 | 0.54 | ±0.27 | 0.78 | ±0.39 | 1.1 | ±0.55 |

| 16 | 25 | 0.3 | ±0.15 | 0.42 | ±0.21 | 0.58 | ±0.29 | 0.82 | ±0.41 | 1.2 | ±0.6 |

| 25 | 40 | 0.32 | ±0.16 | 0.46 | ±0.23 | 0.64 | ±0.32 | 0.9 | ±0.45 | 1.3 | ±0.65 |

| 40 | 63 | 0.36 | ±0.18 | 0.5 | ±0.25 | 0.7 | ±0.35 | 1 | ±0.5 | 1.4 | ±0.7 |

| 63 | 100 | 0.4 | ±0.2 | 0.56 | ±0.28 | 0.78 | ±0.39 | 1.1 | ±0.55 | 1.6 | ±0.8 |

| 100 | 160 | 0.44 | ±0.22 | 0.62 | ±0.31 | 0.88 | ±0.44 | 1.2 | ±0.6 | 1.8 | ±0.9 |

| 160 | 250 | 0.5 | ±0.25 | 0.7 | ±0.35 | 1 | ±0.5 | 1.4 | ±0.7 | 2 | ±1 |

| 250 | 400 | 0.56 | ±0.28 | 0.78 | ±0.39 | 1.1 | ±0.55 | 1.6 | ±0.8 | 2.2 | ±1.1 |

| 400 | 630 | 0.64 | ±0.32 | 0.9 | ±0.45 | 1.2 | ±0.6 | 1.8 | ±0.9 | 2.6 | ±1.3 |

This is the liner tolerance in our foundry.

Geometric Tolerances

Geometric tolerancing is normally applied to the following features of investment casting: Flatness, Straightness, Parallelism, Roundness, Hole Tolerance, Curved Holes, Internal Radii and Fillets, and so on.

Flatness

Flatness tolerance is the total deviation accepted from a flat plane. The investment cast part’s surface must lie between the most flat plane and the plane which will affect the maximum deviation permitted.

The amount of volumetric shrinkage that the wax and metal undergo during cooling will always determine the the degree of flatness of investment castings. This shrinkage is usually in the center of the mass and is referred to as “dish”. This dish can be controlled by specialized techniques, but will always be present to some extent. Due to different configuration and alloys of investment castings, general flatness tolerances cannot be quoted.

Straightness

People are always confused at the differences between straightness and flatness, as it seems so close. When it refers to the tolerance of straightness, the maximum tolerable diameter of the part’s divergence from a perfectly straight line will determine the straightness.

Straightness may be a real problem for some types of investment castings. As it is easy to bend for some relatively thin, short parts. According to our casting experience, we may check if a designed part may bend, but it is difficult to say the bending extent before production. As a rough guide, constant sections tend to experience an axial bow of approximately 0.024 inches per foot.

Parallelism

When you see a blueprint that includes parallel prongs supported only at one end, it means a particular challenge for the completion of precise investment casting. Once there is a parallelism requirement for your part, our engineer in foundry will discuss this issue with you prior to production.

It is difficult to maintain parallelism of these prongs because of volumetric shrinkage of the supporting structure. Yoke holes can also deform substantially as they reach ambient temperature. Careful design adjustment for volumetric shrinkage is critical to achieving an accurate part. These workpieces benefit from more extensive tooling and finishing.

Roundness

The radial difference between a true circle and a given circumference will define the roundness. We can test the roundness by reading the total indicator after rotating the part 360°. Another way to check the roundness is to take half the difference between the maximum and minimum condition. The latter method is recommended as it takes less time and is more efficient .

We measure the roundness by the difference between minimum and maximum radii of a circular part. Our inspection process will strictly control the roundness of a part, and will pick out the parts that falls outside given tolerances.

Concentricity

Concentricity is checked by two cylindrical surfaces sharing a common point or axis as their center. The extent of eccentricity is determined by the dimensional difference in the location of one center with respect to the other. The center of a bore to the outside diameter of a part will be concentric within .003″ for each 1/2″ of wall thickness.

Hole Tolerance

Hole tolerance is the necessary roundness of a cast hole. The surrounding metal of the hole must be symmetrical to provide proper fit and/or clearance. This is extremely important for cast parts which fit together, like wheel shafts, to ensure it will fit tightly without vibration. Longer holes can experience more internal concavity, such that the interior hole diameter is greater than that of the openings. We need to care more to meet specified hole tolerances.

Hole tolerance will be benefit for interior shrinkage, and for diameter up to 1/2 inch, hole clearance could be within +/- .003”, which provides an accurate shape and fit.

Curved Holes, Internal Radii and Fillets

Preformed ceramic cores or a soluble wax can create curved holes. The normal hole tolerance will be doubled to take the curvature into account and all dimensions’ tolerance will be multiplied by two. We cannot size these holes so we provide a diameter tolerance of +/- .005.” For internal radii and fillets, as it is hard to control and inspect, when designed, they should be as wide as possible.

The below part is our Technical Data For Design Reference Standard

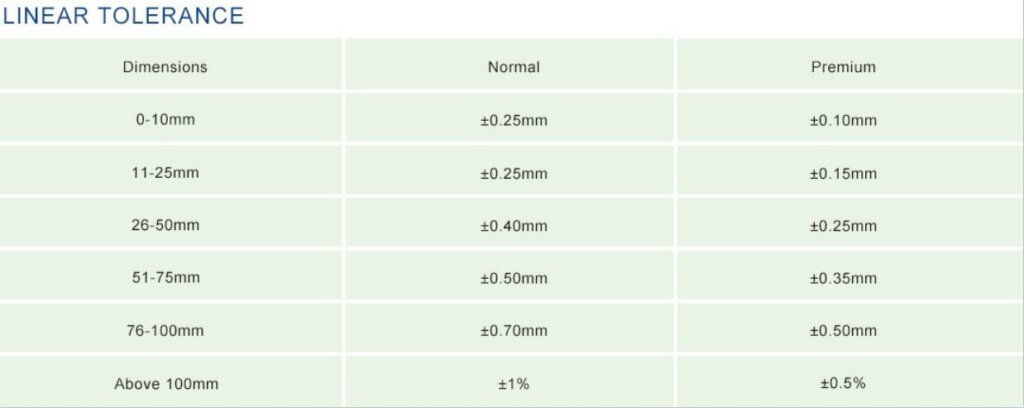

1. Linear Tolerance (mm)

| Dimension (mm) | ≤10 | 10~25 | 25~50 | 50~75 | 75~100 | 100~150 | 150~200 | 200~250 | >250 |

| Normal (mm) | ±0.15 | ±0.25 | ±0.35 | ±0.50 | ±0.65 | ±1.00 | ±1.50 | ±1.80 | ±1.00% |

| Premium (mm) | ±0.10 | ±0.15 | ±0.25 | ±0.40 | ±0.50 | ±0.75 | ±1.00 | ±1.20 | ±0.60% |

2. Tolerance for Flatness, Straightness, Roundness

| Dimension(mm) | 0~25 | 25~50 | 50~100 | 100~150 |

| Tolerance(mm) | 0.2 | 0.4 | 0.6 | 0.8 |

3. Surface Roughness (Ra/μm)

| Ra6.3~3.2 |

4. Limit Dimension for Casting Hole and Slots

| Diameter of Hole(φmm) | Length or Diameter of Hole (L/D) |

| φ2~φ3 | L / D ≤ 1 |

| φ4~φ7 | L / D≤ 2 |

| ≥φ8 | L / D ≤ 2.5 |

| φ2~φ3 | L / D ≤ 2 |

| φ4~φ7 | L / D≤ 4 |

| ≥φ8 | L / D ≤ 5 |

5. Size and Weight Range

| Items | Max | Min | Best |

| Outline Dimensions (mm) | 1000×300×300 | 20×10×10 | <150×100×100 |

| Weight (Kg) | 40 | 0.015 | 0.2~5 |

| Minimum Wall Thickness (mm) | ─ | 1.0 | 5~15 |

6. Suggestion for Structure Design

| √ | ||||

| ╳ |

The factor effects the Tolerance

Tolerances may be affected by a number of factors.

| Mold temperature | wax or plastic temperature | injection pressure |

| mold or shell composition | back up sand | firing temperature |

| rate of cooling | position of the part on the “tree” | heat treat temperature |

Al thought there is a tolerance standard in investment casting industry, it may still vary from foundry to foundry, as some may be specialized in thin wall small parts, and others could be more professional in larger parts. Also the equipment may also has a certain effect on the casting tolerances.