About

JC Casting

—— The Best Casting Supplier

We are the leading investment casting foundry for various metal components in 1997. And we have started our exporting business all over the world. Such as American, Japan, Germany, Australia, UK, Canada, etc.

Currently, our investment casting company has 2 units: one is a foundry, Another one is CNC Machining Factory. There are a total of 310 workers in our factory, with 265 workers, 7 engineers, 23 QC men, 10 salespeople, and 5 management. Via many years’ hard work, we are now have become one of the largest investment casting manufacturers and suppliers.

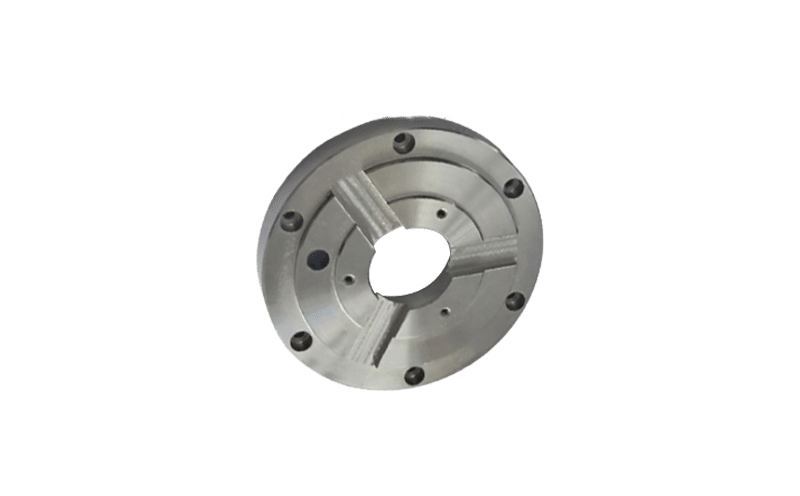

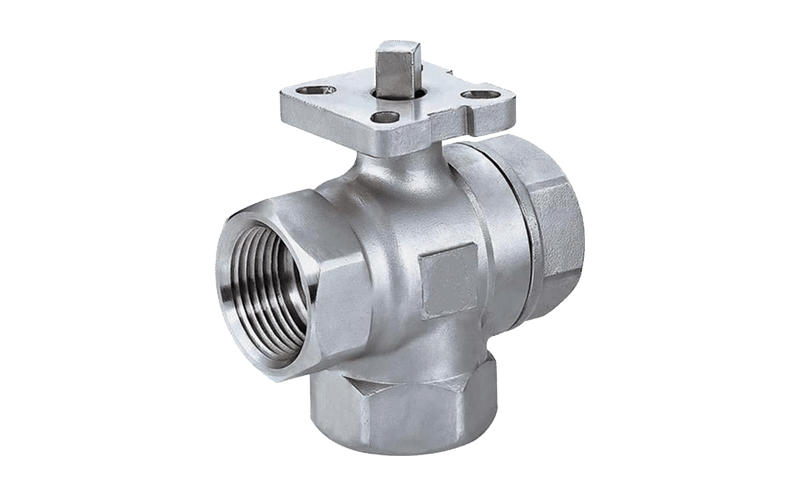

Our company can cast a variety of materials: Alloy Steel, Carbon Steel, Stainless Steel, Aluminum, etc. With great capabilities of design, molding, casting, machining, and heat treatment. With the automatic lost wax investment casting process, we can make custom investment castings for various industries, such as agricultural castings, construction castings, railway castings, valve castings, food machinery castings, and other industrial applications. We are committed to producing Quality Investment Castings at the lowest possible price and on-time delivery. In addition, we offer engineering consultancy services, to assist in the development of new products for best application.

Located in Dongying, Shandong, China. 2.5hours trip to Qingdao Seaport. That will greatly reduce the transportation cost for our customers. As a direct investment casting manufacturer and supplier, we provide a project management service, from initial design to delivery of finished components or assemblies. Pls, do not hesitate to contact us when you need an investment casting solution.

Investment Casting Methods in Our Company

Silica Sol Casting: Medium temperature lost-wax casting process with general tolerance CT5-CT6. Most Widely used for stainless steel products. Also could be used for precision carbon steel parts. This investment casting method allows casting products to range from 0.1kgs to 50kgs.

Water Glass Casting: Low-temperature lost-wax casting process with general tolerance CT7-CT8. More suitable to produce carbon steel and alloy steel products. The capacity of water glass casting is to cast products to range from 0.05kg to 70kgs.

Lost Foam Casting: Another investment casting technic different from lost wax casting. This kind of casting process can achieve casting tolerance CT8-CT9. The weight of products ranges from 0.5kgs to 50kgs. The usually used materials are ductile iron, gray iron, high chrome iron, etc.

Post Treatment

We have a factory of CNC machining. All post-treatment jobs can be finished here. Until now, many domestic investment casting factories send their investment casting products

Why Choose us as your Investment Castings supplier?

Quality Assurance

The investment casting from our foundry must go throughout a district quality inspection process. With ISO 9001:2008 certificated and rich casting experience, we are always getting a good reputation from our customers all over the world.

Various Alloy Materials

Maybe you ever waited months to receive your castings. At our foundry, we can have your investment castings delivered within 30 working days. In addition, our goal is 100% on-time delivery. We work closely with you to guarantee projects move along from design to delivery as fast as we can.

Fast Delivering

Here, you will not need to worry if we can supply the alloys you need, we can make steel casting, iron casting, as well as aluminum casting. Just pls provide the alloy specifications or compositions. We can make accordingly.

Lower Price

Investment casting may seem more expensive than drop forging methods, but it also requires less secondary machining. We focus on creating quality investment cast products and can turn multiple-piece projects into single-piece projects. We think outside the box to create smarter and more efficient castings.

Our Mission

Meet the Team

Featured Staff

20+

Years of RE Experience

50M+

Recent Sales Volume

550+

Clients

The Best Casting Supplier

Work With Us

From different casting technic, raw materials, and different industrial applications, JC casting offers the best products and services!