What is Ductile Iron Casting

Ductile iron casting has round graphite structures found in the metal. It is also known as nodular cast iron. The ductile iron casting is made from molten iron added with carbon. This combination makes Ductile iron casting efficient against fatigue and wear.

Ductile iron casting is a preferred type of casting because of its great properties. It has good hardness and tensile strength. Ductile iron also has high compressive strength, fatigue strength. It is corrosion-resistant and good at withstanding impact. These properties make it a popular casting as it shows reliability.

Ductile Iron Castings Advantages

Ductile iron castings have advantages of low melting point, good fluidity, and machinability. At the same time, It has many similar steel advances of high strength, ductility, and wear resistance. These qualities allow for higher tensile and yield strength. As a commercial product, Ductile iron castings offer lots of distinct advantages.

1–Higher strength-to-weight ratio. It is about 10% lighter than some competing steel alloys. Its weight contributes to its popularity because manufacturers can ship it cost-effectively in some circumstances.

2– Excellent surface finish. This will require less finishing after casting.

3– Good impact well. It permits more machining. Such as drilling, cutting, and surface treatments.

4–Corrosion resistance. withstand heavy wear. Such as applications of Buried ductile iron water and wastewater pipes

5–Ductile iron supplies an excellent casting material. It can create a wide array of products by using this metal alloy. Sometimes, ductile iron castings provide a cost-effective substitute for other metal alloys.

Standard specification for ductile iron castings.

ASTM A536 refers to the standard specifications for ductile iron castings. As per Ductile iron grade, it offers different properties.

A536 Grade 60-40-18 has maximum ductility, excellent machinability, and low-temperature toughness.

A536 Grade 120-90-02 has very high strength and wear resistance (though not as wear-resistant as our chrome white irons).

If you need moderate ductility and impact resistance, coupled with high strength, ASTM A536 Grade 80–55–06 is a good choice.

Our ductile iron castings meet the ASTM A536 standard. This ensures that our customers obtain the engineered properties required for their specific application. All of our castings are manufactured with the latest heat treatment/chemistry design and controls.

We offer several grades of ductile iron casting, including:

- ASTM A536 Grade 60-40-18

- ASTM A536 Grade 65-45-12

- ASTM A536 Grade 80-55-06

- ASTM A536 Grade 100-70-03

- ASTM A536 Grade 120-90-02

- Solid Solution Ductile Iron

- Low-Temperature Impact Resistant ASTM A536

- We also pour austenitic ductile iron.

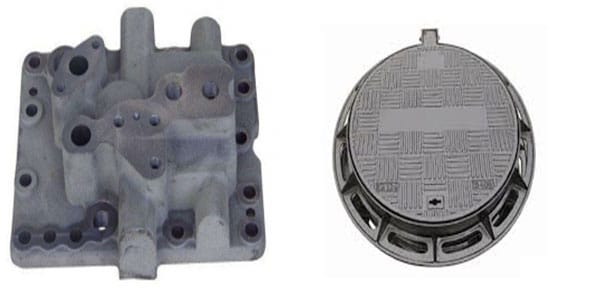

Ductile Iron Castings Applications

Ductile iron has higher strength and ductility than gray iron. Those properties let it be used in a variety of industrial applications. including

- Pipe and pipe fittings (almost 50% of ductile iron sold in the US is for pipe and fittings)

- Axles

- Connecting rods (like in engines)

- Crankshafts

- Cylinders

- Disc brake calipers

- Gears and Gear Boxes

- Housings and manifolds

- Idler arms

- Large Machines

- Machine Tooling

- Spindle supports

- Steering knuckles

- Suspension system parts

- Truck axles

- Valves (especially high-pressure valves)

- Wheel hubs

- wheels,

- gearboxes,

- pump housings,

- Automotive components

Ductile Iron Casting Foundry and supplier

JC casting is a ductile iron foundry in China. We can produce ductile iron casting in different grades. such as Grade 60-40-18, Grade 65-45-12, Grade 80-55-06, Grade 100-70-03, Grade 120-90-02. At present, we use 2 main producing methods for iron casting: lost foam casting and sand casting processes. This is also used for grey iron castings. Besides casting, we also have value-added services of heat treatment, machining, and more.

Contact us for your request. You will get the best solution that matches your project. We will determine the best material grade and production process for each custom ductile iron castings. Email us to get a prompt reply: [email protected]