Die casting tools are essential for driving innovation in the automotive industry. JC, a prominent investment casting and machining manufacturer, emphasizes the importance of precision engineering in manufacturing components that meet modern automotive demands for lightweight, durable, and complex parts. These tools deliver benefits such as consistent quality, reduced weight, cost efficiency, and design flexibility, which are critical for producing next-generation vehicles.

JC integrates die casting with its expertise in investment casting and machining, ensuring every tooling solution is optimized for performance and reliability. Applications range from engine blocks to battery housings, with die casting tools enabling advanced designs and materials for improved safety and efficiency. The company also focuses on sustainability, automation, and smart manufacturing, helping automotive manufacturers reduce environmental impact and enhance production capabilities.

As the industry evolves, JC continues to innovate in tool materials, design, and process automation, supporting clients in meeting future automotive challenges. Their holistic, customer-centric approach makes them a preferred partner for automotive die casting solutions, underscoring the critical role of tooling in automotive progress.

In today’s fiercely competitive automotive industry, innovation stands at the forefront of success. As vehicles become smarter, lighter, and more efficient, the demands on manufacturing processes continue to grow. JC, a leader in investment casting and machining, highlights the pivotal role of die casting tools in shaping the automotive landscape. The synergy between precision engineering and advanced tool technologies provides manufacturers with the means to not only keep pace with industry changes but to drive innovation in every facet of vehicle production.

Understanding Die Casting: The Foundation of Automotive Progress

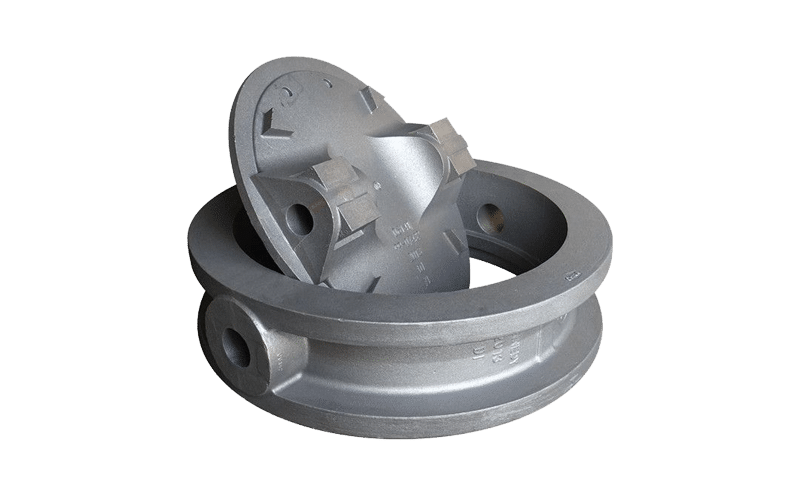

Die casting is a metal forming process that utilizes high-pressure to inject molten metal into a mold cavity. This technique produces complex shapes with exceptional accuracy and repeatability, making it indispensable for automotive components. JC’s expertise in investment casting and machining ensures that each die casting tool meets stringent quality standards, enabling mass production of parts that are both durable and lightweight. The adoption of high-performance die casting tools is integral to meeting the rigorous demands of modern vehicles, from engine blocks to intricate electronic housing.

Key Benefits of Advanced Die Casting Tools in Automotive Manufacturing

Precision and Consistency

Automotive components require tight tolerances and consistent quality. JC’s die casting tools are designed to deliver parts with minimal variation, supporting reliable assembly and long-term performance. This precision improves safety and reduces the risk of component failure, helping manufacturers uphold their reputations for quality.

Lightweight Solutions

With the push towards fuel efficiency and electric vehicles, reducing weight is essential. Die-cast aluminum and magnesium components produced with JC’s tooling technology provide the strength needed for automotive applications while helping reduce overall vehicle mass. This translates into improved fuel economy and lower emissions, aligning with global sustainability targets.

Cost Efficiency

JC’s advanced die casting tools optimize material usage and cycle times, significantly lowering production costs. Streamlined processes enable manufacturers to produce high volumes of automotive parts with fewer resources, allowing savings to be invested in research and development for future innovations.

Design Flexibility

Automotive designers are constantly challenged to create parts with complex shapes and internal geometries. JC’s die casting solutions allow for the realization of intricate designs that would be impossible or cost-prohibitive using traditional machining methods. This flexibility encourages bold innovations in vehicle aesthetics and functionality.

JC’s Role: Integrating Die Casting Tools with Investment Casting & Machining Expertise

JC combines its mastery of investment casting and precision machining with die casting technologies to offer automotive manufacturers an unparalleled suite of solutions. This integration ensures every tool is engineered for optimal performance, durability, and ease of maintenance. The company’s commitment to innovation means continuous investment in research, material science, and process optimization, keeping clients ahead of industry trends.

Applications of Die Casting Tools in Automotive Innovation

| Component | Role in Innovation |

|---|---|

| Engine Blocks | Lightweight, high-strength structures for improved performance |

| Transmission Housings | Complex shapes with integrated cooling features |

| Electronic Module Casings | Precision protection for sensitive electronics |

| Chassis Components | Enhanced safety and reduced weight |

| Battery Housings (EVs) | Thermal management and structural integrity |

Innovation Drivers: How Die Casting Tools Propel Automotive Progress

Enhanced Material Technologies

JC’s ongoing research into new alloys and tool coatings results in die casting tools that are more resistant to heat, corrosion, and wear. This allows automotive manufacturers to push the boundaries of material performance, producing components suited for extreme operating conditions.

Automation and Smart Manufacturing

Modern die casting tools are integrated with Industry 4.0 technologies, including sensors and real-time data analytics. JC leads the way in providing tooling solutions that facilitate predictive maintenance, quality control, and automated process adjustments, resulting in higher efficiency and reduced downtime on automotive production lines.

Sustainability and Environmental Impact

JC’s die casting tools are designed for maximum energy efficiency and minimal waste generation. By optimizing mold designs and casting processes, manufacturers can significantly reduce their environmental footprint, supporting the automotive industry’s transition to greener production standards.

Challenges and Solutions in Die Casting Tool Development

Material Selection

Choosing the right tool materials is critical for longevity and performance. JC partners with leading material suppliers to ensure each die casting tool is tailored to the specific needs of automotive components, balancing hardness, thermal conductivity, and machinability.

Tool Design Complexity

As automotive components become more intricate, so too must die casting tools. JC utilizes advanced simulation software and rapid prototyping to test and refine tool designs, shortening development cycles and improving final product quality.

Quality Control

Maintaining high standards in die casting tool production is non-negotiable. JC implements rigorous quality assurance protocols, including dimensional inspections, material analysis, and performance testing, ensuring every tool meets or exceeds industry specifications.

The Future: Die Casting Tools as Catalysts for Automotive Innovation

- Integration with Additive Manufacturing

- Smart Tooling with Embedded Sensors

- Eco-friendly Materials and Coatings

- Greater Customization for EV Platforms

- Global collaboration for technological advancement

JC’s Commitment to Automotive Excellence

JC’s dedication to engineering precision, investing in technology, and supporting its clients through every phase of automotive development underscores the importance of die casting tools in fostering innovation. The company’s ongoing investment in research, materials, and process automation ensures that automotive manufacturers have the resources needed to meet future challenges head-on.

Why Choose JC for Die Casting Tools?

Proven Expertise

With decades of experience in investment casting and machining, JC is uniquely positioned to deliver die casting tools that meet the evolving demands of the automotive industry.

Holistic Solutions

JC’s integrated approach covers design, prototyping, tooling, production, and quality assurance, offering clients a one-stop solution for all their automotive component needs.

Customer-Centric Philosophy

JC partners closely with automotive OEMs and suppliers, providing tailored support, rapid responses, and collaborative innovation to ensure every project’s success.

Tags:alloy steel casting,marine hardware,medical investment casting,grey iron casting