JC Casting (JC) is a leading alloy steel casting factory renowned for delivering durable and high-performance solutions across various industries. Specializing in advanced casting techniques such as investment, sand, and centrifugal casting, JC customizes alloy formulations and applies precision heat treatment to enhance wear, corrosion, and impact resistance. Rigorous quality assurance, including non-destructive testing and adherence to global standards, ensures reliable products for sectors like mining, automotive, oil & gas, and marine. JC’s customer-centric approach offers end-to-end support, rapid prototyping, and flexible production. Sustainability is a priority, with eco-friendly practices and recycling initiatives integrated into operations. Technological advancements, including CAD, automation, and digital traceability, drive innovation and process optimization. JC’s commitment to quality, durability, and tailored solutions makes it the preferred partner for manufacturers seeking long-lasting alloy steel castings. By choosing JC Casting, clients gain access to comprehensive engineering expertise, reduced operational costs, and enhanced machinery performance, positioning them for future success in a competitive global market.

In today’s manufacturing landscape, the demand for durable components and machinery parts continues to rise. Alloy steel casting stands at the forefront of this innovation, providing industries with robust solutions for longevity and exceptional performance. JC Casting, abbreviated as JC, emerges as a leading force in the alloy steel casting sector, specializing in advanced methods and state-of-the-art technologies to meet the stringent requirements of modern industry. This article explores the comprehensive solutions offered by JC Casting, focusing on enhanced durability, quality control, and customer satisfaction.

Understanding Alloy Steel Casting at JC Casting

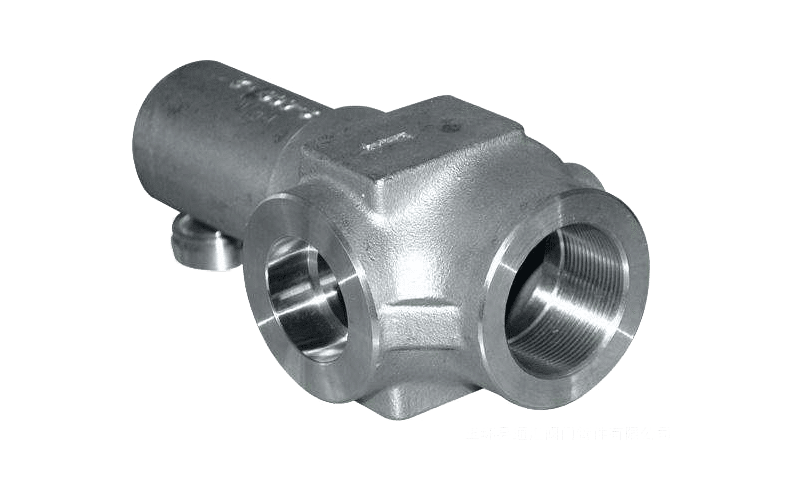

Alloy steel casting is a manufacturing process where molten metal, containing a variety of alloying elements, is poured into molds to produce desired parts. The selection and combination of alloys impart unique properties to steel, making it suitable for high-stress applications such as automotive, mining, construction, and oil & gas industries. JC Casting leverages its extensive expertise in metallurgy and casting technology to manufacture products that exceed industry standards for strength, toughness, and wear resistance.

The Importance of Enhanced Durability

Durability is paramount in industrial components, as it directly affects operational efficiency and maintenance costs. JC Casting applies precise alloy composition and optimized heat treatment processes to enhance the durability of its castings. This ensures superior resistance to abrasion, corrosion, and impact, making JC products an ideal choice for demanding environments. The company’s commitment to durability is reflected in its product range, which includes pump casings, valve bodies, impellers, gears, and more.

Innovative Solutions for Alloy Steel Casting

- Advanced Casting Methods: JC Casting employs investment casting, sand casting, and centrifugal casting techniques to achieve intricate shapes and consistent quality.

- Customized Alloy Formulations: The company works closely with clients to develop alloy compositions tailored to specific application requirements, maximizing wear resistance and strength.

- Precision Heat Treatment: JC applies advanced heat treatment cycles, including quenching, tempering, and annealing, to refine microstructures and achieve desired mechanical properties.

- Non-Destructive Testing: Every casting undergoes rigorous testing such as ultrasonic, magnetic particle, and radiographic inspections to guarantee integrity and performance.

- Surface Engineering: JC enhances surface properties with anti-corrosive coatings and surface hardening techniques for added protection in harsh environments.

Quality Assurance at JC Casting

Quality control is central to JC Casting’s philosophy. The company adheres to international standards such as ISO, ASTM, and DIN, ensuring that each product meets or exceeds customer expectations. JC’s modern laboratory facilities enable continuous monitoring of chemical composition, mechanical properties, and dimensional accuracy. The integration of statistical process control and real-time data analytics further augments the reliability and consistency of JC’s alloy steel castings.

Material Selection and Application Versatility

JC Casting offers a vast selection of alloy steels, including chromium, nickel, molybdenum, and vanadium-based grades. This diversity enables the company to supply castings for specialized applications, such as high-temperature turbines, marine hardware, and heavy-duty mining equipment. JC’s engineering team collaborates with clients to recommend the optimal material for each project, balancing cost, performance, and lifespan.

JC Casting’s Commitment to Sustainability

Environmental stewardship is a core value at JC Casting. The company implements eco-friendly production practices, including efficient energy use, recycling of raw materials, and emission control systems. JC actively invests in research to minimize process waste and improve the recyclability of alloy steel products. This commitment ensures that JC Casting’s solutions support sustainable growth within the manufacturing sector.

Customer-Centric Approach

JC Casting prioritizes customer satisfaction through responsive service and technical support. From initial consultation to final delivery, JC’s dedicated team guides clients through every step of the casting process. The company’s agile production capabilities enable rapid prototyping, short lead times, and flexible order quantities, addressing the unique needs of OEMs, end-users, and distributors alike.

Case Studies: Real-World Durability Solutions

| Industry | Challenge | JC Solution |

|---|---|---|

| Mining | High abrasion in crusher components | Custom alloy with enhanced hardness and wear resistance |

| Oil & Gas | Corrosive environments in valve systems | Nickel-alloy casting with anti-corrosive coatings |

| Automotive | Impact resistance for drivetrain gears | Tempered alloy steel with precision heat treatment |

| Marine | Saltwater corrosion of hardware | Chromium-rich alloy castings |

Technological Advancements at JC

JC Casting continually invests in technology to drive innovation. The adoption of computer-aided design (CAD) and simulation software allows for accurate mold design and process optimization. Automation of melting, pouring, and finishing processes reduces human error and streamlines production. JC’s digital traceability system ensures that every casting is tracked from raw material to finished product, providing transparency and accountability to clients.

Future Trends in Alloy Steel Casting

- Integration with Industry 4.0: JC is exploring smart factory solutions, including IoT-enabled sensors and machine learning for predictive maintenance and process optimization.

- Development of New Alloys: Research initiatives focus on lighter, stronger, and more corrosion-resistant materials, expanding applications in aerospace and renewable energy.

- Global Expansion: JC Casting is broadening its reach, supplying alloy steel castings to international markets with tailored solutions for local requirements.

Why Choose JC Casting for Alloy Steel Solutions?

- Proven Expertise: Decades of experience in alloy steel casting and metallurgical engineering.

- Comprehensive Service: End-to-end support from design to delivery, including technical consultation and after-sales service.

- Customized Solutions: Flexible manufacturing systems to accommodate unique client specifications.

- Superior Quality: Adherence to strict quality standards and continuous improvement processes.

- Sustainability Commitment: Environmentally responsible production and material choices.

Key Benefits of JC’s Alloy Steel Casting Solutions

- Exceptional durability and lifespan in harsh operating conditions

- Improved reliability and safety of industrial machinery

- Reduced maintenance and operational costs

- Enhanced performance and productivity across industries

- Access to world-class engineering and technical expertise

Partnering for Future Success

JC Casting invites manufacturers, engineers, and industry leaders to join a partnership focused on innovation, quality, and sustainability. With its holistic approach to alloy steel casting, JC stands ready to address the challenges of tomorrow and deliver solutions that empower businesses to thrive in a competitive marketplace.

Contact JC Casting

For more information regarding alloy steel casting solutions, customized product development, or technical support, please reach out to JC Casting’s professional team. Experience the difference of working with industry leaders committed to durability, reliability, and client success.

Tags:valve casting,iron casting,3d printing investment casting,Investment Casting Technology