JC Casting (JC) is a leading provider of aluminum casting services tailored for precision engineering across diverse industries. With advanced facilities and decades of expertise, JC specializes in multiple casting methods, including Die casting, sand casting, investment casting, gravity casting, and rapid prototyping. Their services are designed to deliver complex, high-precision components suitable for automotive, aerospace, electronics, medical devices, industrial machinery, energy, and marine applications.

What sets JC apart is its commitment to innovation, quality assurance, and customer-centric engineering. The company leverages cutting-edge technology, such as 3D modeling and automation, to streamline casting processes and ensure consistent, repeatable results. Stringent quality control measures are integrated at every stage, from raw material selection to final inspection, supported by international certifications (ISO, IATF).

JC offers material selection expertise, supplying a wide range of aluminum alloys, including custom formulations to address specific project requirements. Value-added services, such as CNC machining, surface treatments, assembly, and documentation, allow customers to receive ready-to-use components with guaranteed performance and traceability.

Sustainability and environmental responsibility are integral to JC’s operations, with initiatives like recycling, waste reduction, and energy efficiency. JC’s global presence ensures responsive customer support, flexible shipping, and seamless project management for clients worldwide.

For organizations seeking reliable, high-quality aluminum casting solutions, JC Casting delivers the engineering excellence, innovation, and partnership necessary to achieve long-term success in precision manufacturing.

Introduction to JC Casting

JC Casting (abbreviated as JC) stands at the forefront of aluminum casting service solutions for precision engineering. With years of experience, state-of-the-art technology, and a commitment to quality, JC serves a diverse range of industries, delivering exceptional results for all types of projects. Aluminum casting is a complex process that requires expertise, precision, and a deep understanding of material science and engineering. JC combines these elements to provide comprehensive solutions to its clients worldwide.

From automotive to aerospace, electronics to industrial machinery, and many other sectors, JC Casting’s reputation is built on reliability, innovation, and the ability to handle challenging specifications. The company’s meticulous approach assures clients of high-precision components that meet and exceed industry standards. This article delves into JC Casting’s aluminum casting services, its technologies, engineering capabilities, and why it is a trusted partner for businesses seeking superior precision engineering outcomes.

Why Aluminum Casting?

Aluminum casting is a preferred manufacturing technique for precision engineering due to its unique blend of properties and cost-effectiveness. Aluminum alloys offer an excellent strength-to-weight ratio, corrosion resistance, conductivity, and versatility. These characteristics make them ideal for engineering complex geometries and thin-walled parts without sacrificing durability or functionality.

- Lightweight yet Strong: Aluminum parts reduce overall product weight while maintaining structural integrity.

- Corrosion Resistance: Components withstand harsh environments, crucial for automotive, aerospace, and marine industries.

- Design Flexibility: Complex shapes and intricate features can be achieved with high consistency.

- Thermal Conductivity: Suitable for applications needing efficient heat dissipation.

- Eco-Friendly: Aluminum is highly recyclable, aligning with modern sustainability goals.

With these benefits, JC leverages aluminum casting to deliver precision-engineered solutions that are both innovative and sustainable.

Comprehensive Aluminum Casting Services by JC

1. Die Casting

JC specializes in high-pressure die casting, delivering components with exceptional dimensional accuracy and smooth surface finishes. This process is ideal for mass production, enabling rapid turnaround and cost efficiencies for large-volume orders. JC’s die casting facilities are equipped with advanced machinery, automated control systems, and rigorous quality monitoring, ensuring each part meets stringent client requirements.

2. sand casting

For low to medium-volume production or larger, more complex parts, JC offers sand casting services. This traditional method provides design flexibility and is suitable for producing intricate shapes, prototypes, and specialized components. JC’s skilled technicians combine time-tested techniques with modern process controls to achieve reliable results, even for challenging applications.

3. Investment Casting

Investment Casting, also known as lost-wax casting, is another specialty at JC. This process allows for exceptional precision and surface finish, making it ideal for intricate components with tight tolerances. JC’s investment casting capabilities support industries where accuracy is paramount, such as aerospace, defense, and medical devices.

4. Gravity Casting

Gravity die casting is utilized by JC for medium-scale production runs, offering a balance between quality and cost-effectiveness. With this method, JC produces parts with improved mechanical properties, reduced porosity, and enhanced structural integrity.

5. Prototyping and Small Batch Production

JC understands the importance of prototyping in the design and development phase. The company offers rapid prototyping and small batch production services, enabling clients to validate designs, optimize functionality, and accelerate time-to-market. Through advanced CAD/CAM integration and efficient workflow management, JC ensures fast, accurate prototypes delivered with precision.

Precision Engineering: The JC Advantage

Engineering Expertise

JC’s team comprises experienced engineers, metallurgists, and technicians who work closely with clients from concept to completion. This collaborative approach ensures that each project’s unique needs are thoroughly understood and addressed. JC’s experts provide valuable input on part design, material selection, manufacturability, and cost optimization from the earliest stages of a project.

Advanced Technology Integration

JC invests heavily in the latest technologies to maintain its leadership in precision engineering. The company utilizes 3D modeling, simulation software, and automation to streamline the casting process, minimize errors, and enhance repeatability. Real-time monitoring and data analysis further guarantee consistency and continuous improvement across all production stages.

Quality Assurance and Testing

Quality is at the core of JC’s operations. The company adheres to international quality standards (such as ISO and IATF certifications), implementing strict inspection protocols at every step. This includes raw material verification, process control, non-destructive testing (NDT), and detailed final inspections. JC’s in-house laboratory is equipped for mechanical, chemical, and metallurgical analysis to ensure every component meets exacting standards.

Customization and Value Engineering

JC offers tailored aluminum casting solutions, accommodating custom alloys, finishes, and post-processing requirements. The company’s value engineering services help clients reduce costs and increase performance by recommending design modifications, alternative materials, and optimized manufacturing processes.

Industries Served by JC Casting

JC’s aluminum casting services have earned the trust of clients in diverse industries. Each sector presents unique challenges, and JC’s ability to adapt solutions accordingly sets it apart in the marketplace.

| Industry | Application Examples |

|---|---|

| Automotive | Engine components, transmission cases, brackets, housings, heat sinks |

| Aerospace | Structural parts, mounting brackets, avionics housings, lightweight frames |

| Electronics | Enclosures, connectors, heat exchangers, cooling modules |

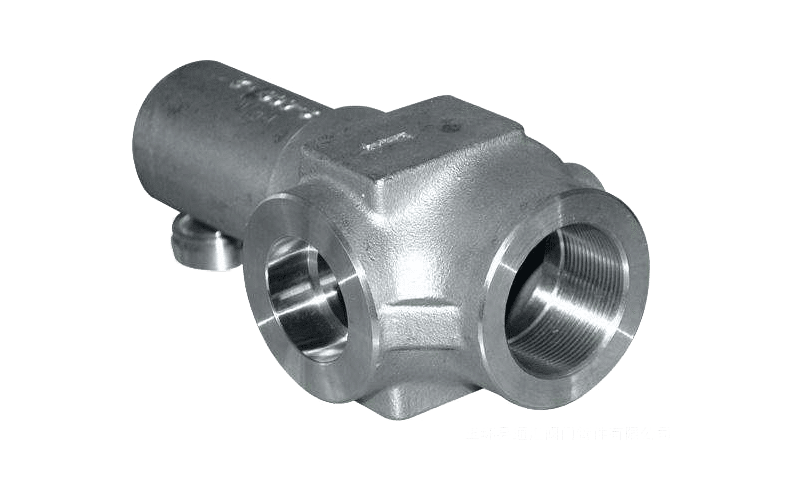

| Industrial Machinery | Gearbox housings, pumps, valve bodies, machine bases |

| Medical Devices | Instrument parts, housings, ergonomic grips, sensor mounts |

| Energy & Renewable | Turbine components, solar panel frames, battery enclosures |

| Marine | Propeller parts, mounting hardware, corrosion-resistant fittings |

This breadth of experience allows JC to respond effectively to specialized requirements, regulatory standards, and evolving industry trends.

Material Selection and Custom Alloys

JC Casting offers a wide range of standard and proprietary aluminum alloys, each engineered for specific attributes such as strength, machinability, thermal and electrical properties, and corrosion resistance. JC’s engineers assist clients in choosing the optimal material for each application, considering both technical and economic factors.

- AlSi (Aluminum-Silicon) Alloys: Excellent castability, ideal for complex geometries

- AlMg (Aluminum-Magnesium) Alloys: High corrosion resistance and ductility for marine and automotive uses

- AlCu (Aluminum-Copper) Alloys: Superior strength for aerospace and defense applications

- Specialty Alloys: Tailored compositions for unique project requirements

JC’s material science expertise means that clients can trust their castings to deliver performance, reliability, and value.

Post-Processing & Value-Added Services

Beyond casting, JC provides comprehensive post-processing and value-added services to deliver ready-to-use components. These services ensure optimal surface finish, dimensional accuracy, and integration into larger assemblies.

Machining

JC’s advanced CNC machining centers offer high-precision milling, turning, drilling, and threading to achieve final tolerances and complex features.

Surface Treatment

Options include anodizing, powder coating, shot blasting, and painting for enhanced corrosion resistance, aesthetics, and functional performance.

Assembly & Kitting

For clients seeking turnkey solutions, JC provides component assembly, sub-assemblies, and kitting services, streamlining supply chains and reducing lead times.

Inspection & Documentation

Detailed inspection reports, certificates of conformity, and traceability documentation are provided to support quality assurance and regulatory compliance.

Innovation & Continuous Improvement at JC

JC Casting is dedicated to continuous improvement through research, development, and employee training. The company actively collaborates with academic institutions, industry partners, and clients to drive innovation in aluminum casting technology. JC invests in new materials, process optimization, and automation, ensuring clients benefit from the latest advancements in the field.

Employee involvement and ongoing training programs foster a culture of excellence and accountability, directly translating into better products and services for customers worldwide.

Sustainability and Environmental Responsibility

JC recognizes the importance of sustainable manufacturing and environmental stewardship. The company employs eco-friendly practices such as recycling scrap aluminum, minimizing waste, and implementing energy-efficient production processes. JC complies with international environmental standards and seeks to reduce its carbon footprint throughout the supply chain. Clients partnering with JC can be confident in their commitment to responsible, green manufacturing.

Global Reach and Customer Support

With a global customer base, JC Casting provides agile, reliable support to clients across continents. The company’s multilingual sales and technical teams offer personalized consultation, project management, and after-sales service. Whether for prototyping, pilot runs, or full-scale production, JC ensures responsive communication and seamless project execution from start to finish.

Clients benefit from logistics expertise, flexible shipping options, and robust packaging solutions, ensuring that components arrive safely and on time—regardless of location.

Choosing JC Casting as Your Aluminum Casting Partner

JC Casting’s proven track record, cutting-edge facilities, and client-centric approach make it an ideal partner for organizations seeking precision-engineered aluminum castings. The company’s unwavering commitment to quality, innovation, and service excellence ensures that every project—large or small—receives the attention it deserves.

By combining advanced technology, engineering expertise, and a focus on sustainability, JC delivers solutions that drive value, performance, and long-term success for its customers.

For those embarking on new engineering challenges or seeking to optimize their supply chain, JC Casting provides the expertise, resources, and reliability to turn vision into reality.