Aluminum and Die Casting Aluminum and Cast aluminum

Aluminum is the third most abundant element on Earth. It is also recyclable. Its lower cost is helpful to creating products at competitive rates.

Aluminum can also withstand the highest operating temperatures of all the die-cast alloys. Moreover, cast aluminum has the advantage of being versatile, corrosion-resistant. It can be used in almost any industry.

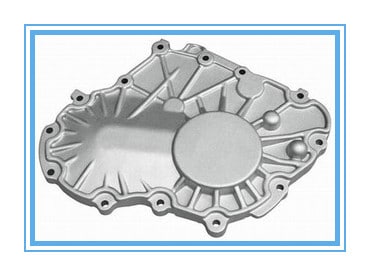

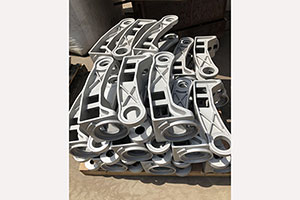

Compared with other die-cast alloys, Aluminum has the ability to create lighter parts with more surface finishing options. Aluminum Die casting is ideal for a great number of applications in industries. Such as consumer products, industrial products, electric motors, and more.

A380 ALUMINUM ALLOY Die Casting

A380 aluminum alloy is widely used for producing die castings. A380 is one of the most commonly specified aluminum alloys with a number of significant benefits. It has exceptional mechanical properties and is used in hundreds of applications such as air brake castings, gear cases, and air-cooled cylinder heads.

Die casting with aluminum alloy A380 in particular produces high-quality, cost-effective parts and products that are durable. The die-cast part or product trims in our presses well without splintering, cracking, or any other potential problems that can be found with other metals. We can apply a variety of finishing services to A380 aluminum as well to meet your specific needs and specifications for use. Additionally, A380’s anti-soldering properties help to extend the life of tools and dies, and the metal’s overall composition reduces machine breakage and downtime.

Aluminum Alloy 380 of Pure aluminum is weak and malleable. But after being mixed with other metals, such as silicon, iron, copper, magnesium, manganese, or zinc strengthens the aluminum and brings other benefits to the metal. Adding silicon and magnesium to aluminum, for example, results in an alloy that is extremely resistant to corrosion.

Aluminum alloy A380 specification

There are more than 500 different alloy compositions with more compositions being created and registered every year. The versatility that aluminum alloys offer is undeniable, and the advantages of A380 make it one of the most widely used alloys for manufacturing and die casting.

Why do we choose A380 aluminum alloy for die-cast? Because of Advantages of A380 Aluminum Alloy as below:

Advantages of A380 Material

- The best combination of casting, mechanical, and thermal properties

- Excellent fluidity, pressure tightness, and resistance to hot cracking

- Wide usage in variety of products. including chassis for electronic equipment, engine brackets, gearbox cases, and hand tools

- Resist hot cracking and corrosion

- Strength at elevated temperatures and ability to perform well at high temperatures during typical use

- Anti-soldering properties during the die casting process,Machining, polishing, and finishing ease

- More versatility in finishing options

- Tensile strength

- Relatively lightweight

A380(alsi8cu3fe) aluminum equivalent

| EU/EN | USA | Germany/DIN, WNr | Japan/JIS | Inter/ISO |

|---|---|---|---|---|

| ENAC-AlSi8Cu3 | 380.0 | G-AlSi9Cu3 | AC4B | AlSi8Cu3 |

A380 Aluminum Alloy Composition

| Elements | Al | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Sn | Ti | Trace |

| %Min | – | 7.50 | – | 3.00 | – | – | – | – | – | – | – | – |

| %Max | – | 9.50 | 1.00 | 4.00 | .50 | .30 | – | .50 | 2.90 | 3.50 | – | 0.50 |

| %Norm | Balance | 8.50 | – | 3.50 | – | – | – | – | – | – | – | – |

A380 Alloy Properties of Physical

| Specific Gravity | 2.71 |

| A380 aluminum alloy density | 0.098 lb/in3 at 68°F |

| Melting Point | – Solidus1,000°F |

| Melting Point | – Liquidus1,100°F |

| Electrical Conductivity | 23% IACS at 68°F |

| Thermal Conductivity | 55.6 Btu/ft/(hr/ft2/°F) at 68°F |

| Coefficient of Thermal Expansion | 12.1 x 10-6 per °F (68°F – 572°F) |

| Specific Heat Capacity | 0.23 Btu/lb/°F at 68°F |

A380 Material Typical Uses

| Consumer | Tools,Frames,Buckets |

| Builder’s Hardware | Enclosures Tools |

| General Hardware | Handles,Knobs,Press Frames |

| Industrial | Pump,Fixtures,Levers Housings,Valve Bodies,Fittings,Covers |

| High Strength, Thin-Walled Die Castings |

Besides the a380 aluminum die casting, we can use other grades of aluminum material. Such as Aluminum: A360, A356, A319, Tenzalloy, A713, A413, A319. If you have any need inquiry about A380 Aluminum Alloy products, please feel free to contact us.