How Does 42CrMo Casting Boost Machine Durability?

When improving heavy machines, 42CrMo casting is a big help. It is very strong and resists wearing out easily. This lets machines handle hard work without breaking down. The material is made to face tough jobs and keep machines working well. If you need great casting, JC Casting makes top 42CrMo parts for you.

Key Points

- 42CrMo casting is tough and lasts long. It works well for heavy machine parts in hard conditions.

- Using 42CrMo casting lowers repair costs by stopping breakdowns.

- This material makes machines safer by handling heat, pressure, and rust. It stops sudden failures.

- Construction, car-making, and mining industries use 42CrMo casting because it is strong and dependable.

- Picking 42CrMo casting for machine parts helps machines last longer and work better.

Understanding 42CrMo Casting

Material Composition and Key Properties

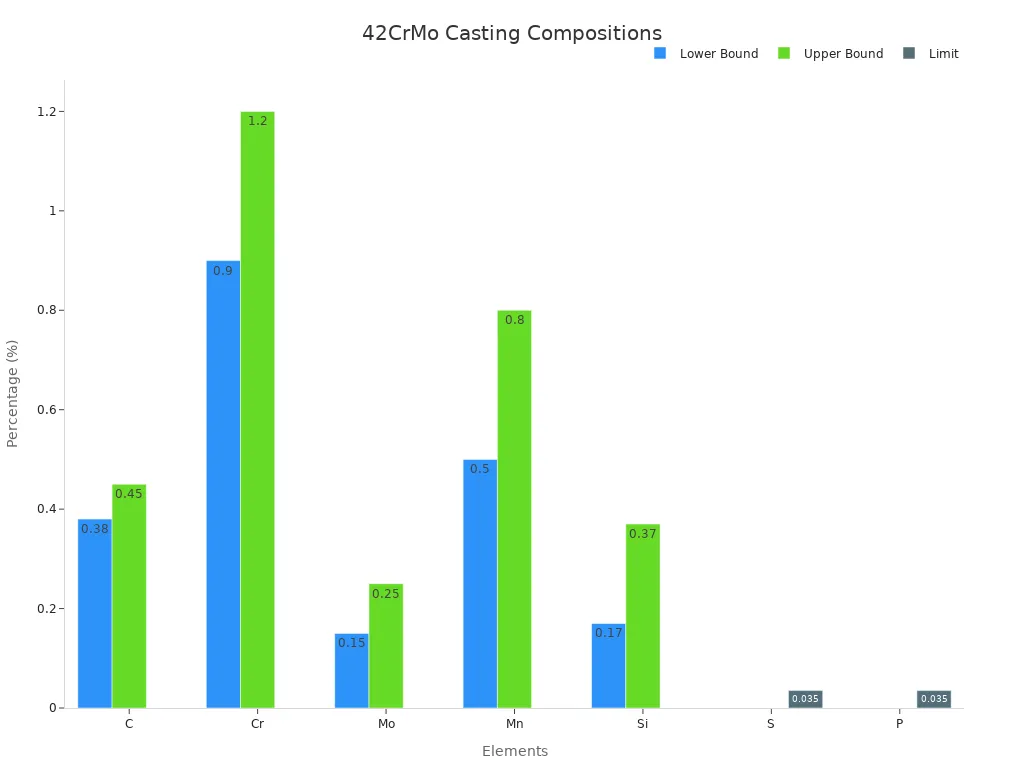

42CrMo casting is special because of its balanced chemical composition. This mix gives it great strength and durability. The steel includes different elements that make it tough and long-lasting. Here’s a simple table showing its composition:

| Element (Symbol and Name) | Percentage Range (%) |

|---|---|

| C (Carbon) | 0.38 – 0.45 |

| Cr (Chromium) | 0.90 – 1.20 |

| Mo (Molybdenum) | 0.15 – 0.25 |

| Mn (Manganese) | 0.60 – 0.90 |

| Si (Silicon) | 0.15 – 0.40 |

| S (Sulfur) | ≤ 0.035 |

| P (Phosphorus) | ≤ 0.035 |

Each element has a job to do. Carbon makes the steel harder and stronger. Chromium helps stop rust and makes it harder to wear out. Molybdenum adds toughness and keeps it strong in high heat. Manganese and Silicon make the steel stronger and last longer under heavy use.

Tip: These elements together make 42CrMo casting perfect for tough parts like gears, shafts, and machine components.

Overview of the Casting Process

Making 42CrMo steel involves careful steps to get the right properties. First, the elements are melted together in a very hot furnace. This mixes them evenly into the steel. Then, the liquid steel is poured into molds to form the needed shape.

After cooling, the steel is treated with heat to make it better. Quenching cools it quickly to make it harder. Tempering makes it less brittle and tougher. These steps improve the steel’s structure so it can handle stress and wear.

Note: The casting process must be done carefully. Good control during melting, molding, and heat treatment ensures the steel works well in heavy machines.

Durability Benefits of 42CrMo Casting

Strong Against Wear

Machine parts often face rubbing and scraping. They need to stay strong. 42CrMo Casting is great at resisting wear. Its special mix of chromium and molybdenum makes the surface tough. This helps stop scratches and damage. It works well for gears and shafts that are always moving.

Tip: Choosing 42CrMo Casting for high-wear parts keeps machines running longer.

Handles Heavy Loads

Big machines carry heavy weights. Their parts must not bend or break. 42CrMo Casting is very strong because of its fine structure. After forging, its grains shrink from 273 μm to 12 μm. This makes it much tougher. Its dislocation density grows to 2.35 × 10^15 m−2, helping it resist stress.

- Forged parts are 1.7 times stronger than regular ones.

- Annealing doubles stretchability from 8% to 16%. Yield stress ranges from 798 MPa to 522 MPa.

This makes 42CrMo Casting perfect for axles and rods that carry heavy loads.

Works in Tough Conditions

Machines often face heat, pressure, and chemicals. 42CrMo Casting stays strong in these tough spots. Molybdenum helps with heat, and chromium stops rust. It keeps working well even under stress.

Note: Using 42CrMo Casting for key parts reduces breakdowns and costly fixes.

Applications of 42CrMo Casting in Heavy Machinery

Common Components Made from 42CrMo

42CrMo casting is used in many important machine parts. It is strong and lasts long, making it perfect for tough jobs.

- Gears: Gears move power between machine parts. 42CrMo casting helps them stay strong and accurate under heavy use.

- Shafts: Shafts support spinning parts in machines. With 42CrMo casting, they handle twisting and bending better.

- Axles: Axles carry heavy loads and help things move smoothly. 42CrMo casting makes them tough for hard tasks.

- Hydraulic Cylinders: These parts work under high pressure in machines. 42CrMo casting keeps them from bending or breaking.

Tip: Pick 42CrMo casting for parts that face heavy use, motion, or tough conditions.

Industries Relying on 42CrMo Casting

Many industries use 42CrMo casting to keep machines working well. Its special features make it great for strong and reliable parts.

- Construction: Machines like cranes and bulldozers need 42CrMo casting for parts that take hits and stress.

- Automotive: Cars and trucks use 42CrMo casting for axles, gears, and suspension to stay safe and efficient.

- Mining: Mining tools face rough use and heavy loads. 42CrMo casting makes drill rods and crusher parts last longer.

- Oil and Gas: This industry needs parts that handle heat and pressure. 42CrMo casting works well for valves and pipelines.

- Manufacturing: Factory machines use 42CrMo casting for gears, shafts, and hydraulic parts to stay precise and reliable.

Note: Using 42CrMo casting in machines improves performance and reduces downtime in many industries.

Advantages of Using 42CrMo Casting

Extended Equipment Lifespan

Using 42CrMo Casting makes your machines last much longer. This material is tough and resists wearing out over time. It handles heavy loads and constant use without breaking down. For instance, gears and shafts made from 42CrMo Casting stay strong even after years of work.

Tip: Choosing durable materials like 42CrMo Casting means fewer replacements and longer-lasting equipment.

Cost Savings in Maintenance and Repairs

Fixing machines often can cost a lot of money. With 42CrMo Casting, you spend less on repairs. Its strength and wear resistance reduce breakdowns and downtime. Parts like hydraulic cylinders and axles need less fixing, saving both time and money.

- Reduced Downtime: Machines work longer, boosting productivity.

- Lower Repair Costs: Strong parts mean fewer fixes and replacements.

Note: Using 42CrMo Casting helps you save money and focus on growing your business.

Improved Safety in Industrial Operations

Safety is very important in industries. 42CrMo Casting makes machines safer by working well under tough conditions. It resists heat, pressure, and rust, preventing sudden failures. This is especially important for jobs like mining and construction.

Callout: Reliable machines lower risks and create a safer workplace for everyone.

Adding 42CrMo Casting to your machines improves performance, saves money, and keeps workers safe.

42CrMo Casting is important for heavy machines. It is strong and lasts long, even in tough conditions. Using it for key parts lowers repair costs and makes machines safer. This material works well in many industries like construction and manufacturing. Choosing 42CrMo Casting helps machines work better and stay useful for a long time.

Tip: High-quality materials like 42CrMo Casting improve work output and reduce delays.

FAQ

What makes 42CrMo casting better than other materials?

42CrMo casting is very strong and lasts a long time. Its special mix of chromium and molybdenum helps it work well under stress. It’s perfect for heavy machines and tough jobs.

Tip: Pick 42CrMo casting for parts that need to stay tough and reliable.

Can 42CrMo casting reduce maintenance costs?

Yes, it can. Its toughness and wear resistance keep parts from breaking. This means fewer repairs and replacements, saving money over time.

Is 42CrMo casting suitable for high-temperature environments?

Yes, it is. The molybdenum in it helps handle high heat. This makes it great for industries like oil, gas, and manufacturing.

Which industries benefit the most from 42CrMo casting?

Industries like construction, mining, and automotive use it a lot. Its strength makes it great for gears, shafts, and hydraulic parts.

How does 42CrMo casting improve machine safety?

42CrMo casting keeps machines safe by resisting heat and pressure. It stops sudden failures, making work safer and smoother.

Callout: Stronger machines mean fewer accidents and safer workplaces.