Brass casting is pivotal in modern manufacturing, prized for its durability, machinability, and corrosion resistance. JC, a leading Investment Casting & Machining Manufacturer, offers advanced distributor solutions designed to deliver excellence in brass component supply chains. Leveraging investment casting technology, JC produces intricate, high-precision brass parts with minimal need for secondary processing, ensuring consistent quality and cost efficiency. Their state-of-the-art machining centers provide additional value, delivering fully finished components tailored to distributor needs. JC’s end-to-end support includes collaborative engineering, rapid prototyping, flexible order sizes, and robust logistics management, ensuring that distributors can swiftly adapt to market demands. Quality is ensured through rigorous inspection, testing, and adherence to international certifications like ISO 9001 and IATF 16949. JC’s adoption of digital manufacturing, process automation, and sustainability initiatives positions them as a forward-thinking partner. Serving industries from plumbing and automotive to electrical and marine, JC’s expertise empowers distributors to deliver reliable, application-specific brass products worldwide. Their commitment to continuous improvement and innovation ensures that JC remains a top choice for distributors seeking manufacturing excellence in brass casting.

Brass casting has long been a cornerstone of component manufacturing, especially for applications demanding precision, durability, and corrosion resistance. In the evolving landscape of global manufacturing, finding a reliable partner that delivers brass casting distributor solutions with advanced manufacturing excellence is essential. JC, a prominent Investment Casting & Machining Manufacturer, stands at the forefront of this industry by providing comprehensive brass casting solutions tailored for distributors and OEMs worldwide. This article delves into JC’s capabilities, technical expertise, and commitment to innovation, illuminating how the company enables its clients to achieve superior outcomes.

The Significance of Brass Casting in Modern Industry

Brass, an alloy of copper and zinc, offers remarkable properties that make it ideal for a variety of industrial uses. Its excellent machinability, workability, and resistance to corrosion drive its application in sectors such as plumbing, automotive, electrical, marine, and architectural hardware. Distributors and manufacturers require not only consistent quality but also flexibility in product customization and delivery.

JC recognizes these unique demands and addresses them by leveraging its advanced investment casting and machining capabilities. This ensures that every distributor receives products that align with their quality standards, technical requirements, and market expectations.

JC’s Investment Casting Capabilities

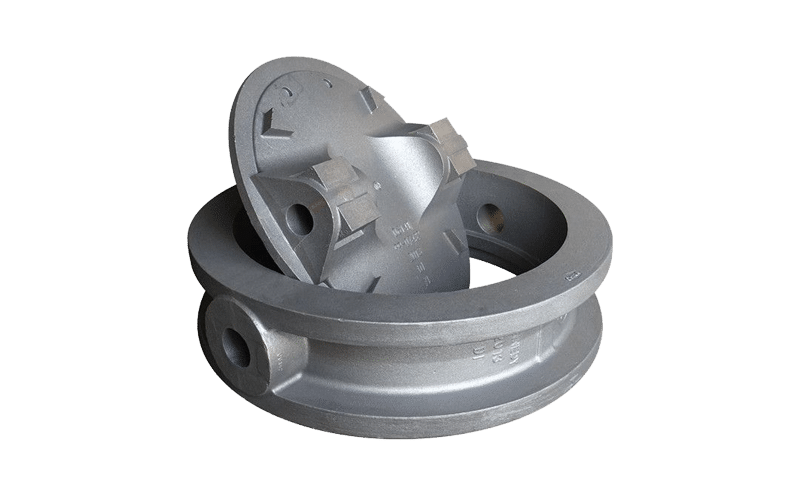

Precision and Complexity in Brass Components

Investment casting, also known as lost wax casting, is a manufacturing process renowned for its ability to produce intricate and highly detailed components. JC’s advanced investment casting facilities allow for the creation of brass parts with tight tolerances and complex geometries, reducing the need for secondary machining and minimizing material waste.

Key Advantages of JC’s Investment Casting for Distributors:

- High dimensional accuracy and consistent repeatability

- Ability to create thin-walled and intricate shapes

- Superior surface finish compared to traditional sand casting

- Reduced post-casting machining requirements

- Support for both small and large production runs

- Compatibility with various brass alloys for specific end-use requirements

By offering these benefits, JC empowers distributors to cater to industries requiring both specialized and mass-produced brass components.

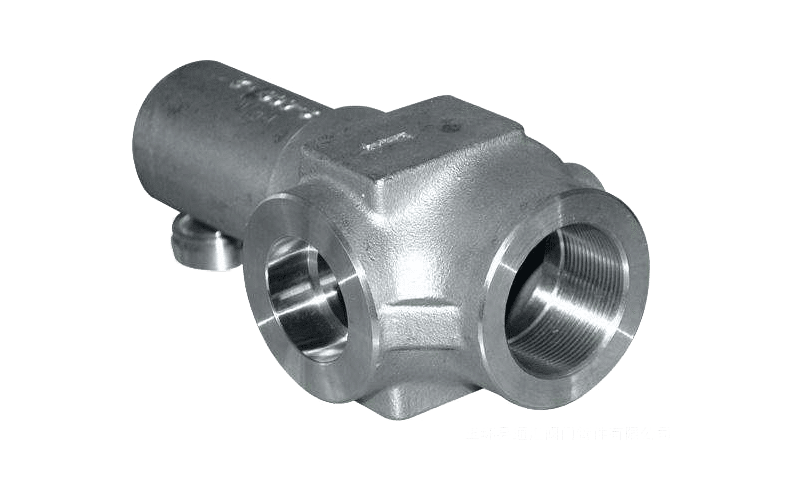

Machining Excellence for Enhanced Product Value

Beyond casting, JC operates state-of-the-art machining centers equipped with advanced CNC technology. This enables the company to provide value-added services such as drilling, milling, turning, threading, and surface finishing directly after casting. Distributors can thus obtain fully finished brass products from a single, reliable source.

Benefits of JC’s Machining Solutions:

- Shortened lead times through integrated manufacturing

- Consistent quality assurance from raw material to finished component

- Comprehensive inspection and testing capabilities

- Flexibility to accommodate custom specifications and special features

With continual investment in operator training and machine upgrades, JC remains committed to delivering top-tier machined brass components that meet the rigorous demands of global distributors.

Custom Brass Casting Distributor Solutions

Tailored Services for Distributors and OEMs

JC understands that every distributor faces unique challenges, from market-specific product requirements to complex logistics and inventory management. The company offers end-to-end support designed to streamline the supply chain and foster enduring partnerships.

JC’s Distributor Support Services Include:

- Collaborative engineering and design assistance

- Rapid prototyping and sample production

- Flexible order quantities for small and large-scale needs

- Just-in-time delivery and global logistics management

- Comprehensive after-sales technical support

Through continual communication and adaptive manufacturing processes, JC helps distributors respond quickly to changing market trends and customer preferences.

Quality Assurance and Certifications

Quality is at the heart of JC’s business philosophy. The company maintains stringent quality control procedures throughout every stage of the production process, from alloy selection and wax pattern creation to final inspection and packaging.

Inspection and Testing Capabilities:

- Spectrometer analysis for precise alloy composition

- Dimensional inspection with CMM and optical comparators

- Non-destructive testing methods (NDT), including X-ray and ultrasonic testing

- Pressure, leak, and mechanical property testing

JC’s factories are ISO 9001 and IATF 16949 certified, verifying the company’s commitment to process control and quality management. These certifications assure distributors and end users of the reliability and traceability of every component delivered.

Advanced Technology and Process Innovation

JC embraces continual technological advancement to remain competitive in the global brass casting industry. The company invests in digital manufacturing solutions, process automation, and real-time production monitoring systems. These efforts enhance operational efficiency, reduce cycle times, and improve overall product consistency.

- Adoption of simulation software for casting process optimization

- Use of ERP systems for streamlined order tracking and inventory management

- Integration with client IT systems for enhanced supply chain transparency

This dedication to innovation distinguishes JC as a strategic sourcing partner for distributors seeking reliability, scalability, and future-ready solutions.

Sustainable Manufacturing Practices

JC is committed to environmentally responsible manufacturing. The company incorporates recyclable materials, energy-efficient melting systems, and waste minimization initiatives to reduce its environmental footprint. Distributors working with JC can be confident in the sustainability of their supply chain, an increasingly important consideration for global markets and conscientious end-users.

- Water and energy conservation programs

- Safe handling and recycling of casting byproducts

- Compliance with REACH, RoHS, and other environmental standards

Industry Applications and Case Studies

JC’s brass casting and machining solutions support a broad spectrum of industries. Distributors serving diverse markets rely on JC’s expertise to deliver application-specific components with uncompromising quality.

Industries Served by JC:

- Plumbing and sanitary fittings

- Automotive parts and accessories

- Electrical connectors and terminals

- Marine hardware and shipbuilding

- Architectural and decorative hardware

- Aerospace and defense (select applications)

Selected Case Study: Plumbing Solutions Distributor

A leading European plumbing distributor partnered with JC to source customized brass valves and fittings. JC’s engineering team collaborated with the distributor’s technical staff to optimize designs for performance and manufacturability. Through investment casting and integrated machining, JC delivered components that exceeded the distributor’s expectations for quality and lead time, enabling faster time-to-market and increased customer satisfaction.

Why Distributors Choose JC

Key Attributes Setting JC Apart

| Attribute | JC’s Solution |

|---|---|

| Technical Expertise | Highly skilled engineers and process specialists |

| Manufacturing Flexibility | Ability to handle custom and high-volume orders |

| End-to-End Services | Design, prototyping, casting, machining, finishing, and logistics |

| Quality Assurance | Comprehensive in-house inspection and certification |

| Global Reach | Experience serving distributors across Europe, North America, Asia, and beyond |

Continuous Improvement and Future Vision

JC is not content to rest on its laurels. The company actively pursues process improvement through Lean Manufacturing, Six Sigma, and employee training initiatives. This ensures that distributors benefit not just from current competencies but from a culture of perpetual advancement and adaptability.

As the manufacturing sector evolves—incorporating new alloys, digital manufacturing, and sustainable practices—JC remains committed to innovation, helping its distributor partners stay ahead of industry trends and regulatory requirements.

Tags:investment casting process,water glass casting,pump castings