JC is a premier Investment Casting and machining manufacturer specializing in precision aluminum components for industries such as aerospace, automotive, medical devices, and industrial equipment. The company leverages advanced technologies—including CAD modeling, robotic shell building, real-time process monitoring, and sophisticated CNC machining—to achieve extremely tight tolerances and consistently high-quality products. Precision is the cornerstone of JC’s operations, impacting everything from mechanical performance to cost efficiency and customer satisfaction. JC’s commitment to quality assurance, rigorous process control, and sustainability ensures that each part not only meets specifications but also aligns with environmental stewardship. By collaborating with customers throughout the manufacturing lifecycle and investing in future-ready innovations such as digital twins and machine learning, JC continues to push the boundaries of what’s possible in aluminum casting. Their approach results in lower defect rates, shorter lead times, and enhanced reliability, making them a trusted partner for critical and complex component manufacturing.

Introduction to JC: Leaders in Investment Casting & Machining

JC stands at the forefront of aluminum casting foundry manufacturing, transforming the industry with a relentless pursuit of precision, innovation, and reliability. As a specialist in investment casting and advanced machining, JC has redefined what’s possible in producing intricate, high-performance aluminum components for a myriad of sectors including aerospace, automotive, medical devices, and industrial equipment. The question of how precision can revolutionize aluminum casting is central to understanding both JC’s capabilities and the broader potential for manufacturing excellence in this field.

The Fundamentals of Aluminum Casting

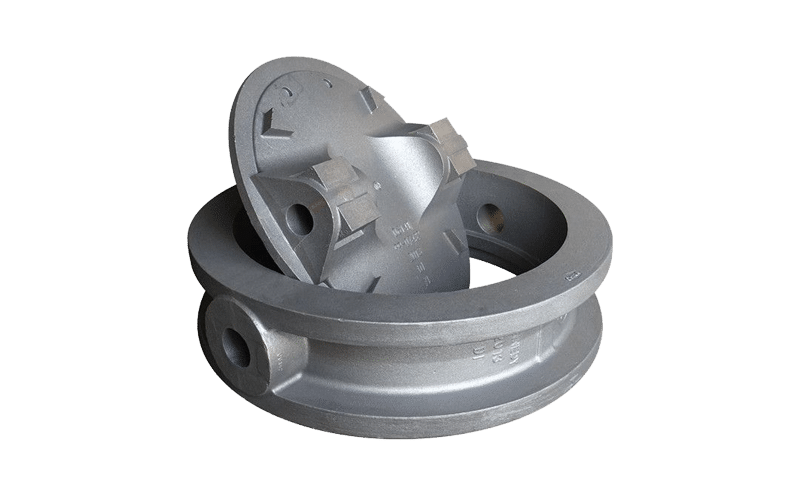

Aluminum casting foundries have long been the backbone of manufacturing, offering a lightweight, durable, and corrosion-resistant material solution for a plethora of applications. The investment casting process, used extensively by JC, enables the creation of complex geometries that would be difficult, if not impossible, with traditional fabrication methods. This process begins with the creation of a wax pattern, followed by the formation of a ceramic shell, and finally the pouring of molten aluminum to form the desired component. The precision with which these steps are executed is crucial, impacting everything from dimensional accuracy to surface finish.

Why Precision Matters in Aluminum Casting

Precision in aluminum casting transcends mere technical requirements—it is the difference between a functional product and one that fails in the field. JC’s investment in state-of-the-art equipment, rigorous process control, and continual training ensures every cast part adheres to strict tolerances and customer specifications. High precision leads to superior mechanical properties, optimal fit for assembly, and enhanced aesthetic qualities. For critical sectors like aerospace, where even a minor deviation can have catastrophic consequences, JC’s dedication to precision is both a competitive advantage and a moral imperative.

The Role of Technology in Precision Foundry Operations

Modern foundries like JC leverage a suite of technological advancements to push the boundaries of what aluminum casting can achieve. Key among these are:

- Computer-Aided Design (CAD): Enables exact modeling and simulation of parts prior to physical production.

- Automated Wax Pattern Production: Increases consistency and reduces human error.

- Robotic Shell Building: Ensures uniformity and structural integrity in the ceramic shell phase.

- Real-Time Process Monitoring: Tracks temperature, pressure, and other vital parameters during pouring and cooling.

- Advanced Non-Destructive Testing (NDT): Provides rapid feedback on part quality without damaging the product.

Implementation of these technologies enables JC to maintain tight dimensional tolerances, reduce scrap rates, and deliver parts that perform reliably even under extreme conditions.

Machining: Elevating Precision to New Heights

While investment casting is exceptionally precise, some applications demand even greater accuracy or specialized surface finishes. JC complements its foundry operations with sophisticated machining capabilities, including CNC milling, turning, grinding, and electrical discharge machining (EDM). By integrating machining with casting, JC provides customers with finished components that meet the most challenging requirements for fit, function, and aesthetics.

Quality Assurance: The Heart of Precision Manufacturing

Quality assurance is embedded in every facet of JC’s foundry and machining operations. From incoming material inspection to final dimensional verification, each step is governed by comprehensive protocols and international standards such as ISO 9001 and AS9100.

- Material Traceability: Ensures all aluminum alloys are sourced and certified for optimal performance.

- Process Documentation: Maintains detailed records for every batch and part produced, facilitating root cause analysis and continuous improvement.

- Final Inspection: Utilizes coordinate measuring machines (CMM), digital calipers, and other precision tools to verify conformance to specifications.

- Customer Feedback Loops: Drives enhancements in process and product quality based on real-world application data.

JC’s unwavering commitment to quality means customers can trust that every product will meet or exceed expectations, regardless of complexity or volume.

Case Studies: Precision in Action at JC

JC’s portfolio showcases how precision transforms casting outcomes across diverse industries:

- Aerospace: JC supplies critical engine brackets and control housings with tolerances as tight as +/- 0.01mm.

- Automotive: Lightweight transmission housings and intricate turbocharger parts, optimized for high performance and durability.

- Medical Devices: Implantable aluminum components with flawless biocompatibility and surface finishes ensuring patient safety.

- Industrial Equipment: Pump impellers and valve bodies engineered to exacting standards for long-term reliability.

Each case underscores JC’s ability to marry design complexity with manufacturing precision, delivering tangible value and competitive differentiation for their clients.

Material Advancements and Alloy Selection

JC’s dedication to precision extends to the careful selection and ongoing development of aluminum alloys. Working closely with metallurgists and material scientists, JC adapts formulations to maximize strength, ductility, corrosion resistance, and thermal properties for specific applications.

The ability to tailor alloy compositions provides JC with the flexibility to meet unique customer requirements and regulatory standards, further enhancing the value proposition and reliability of every cast part.

Sustainability in Precision Aluminum Casting

Precision and sustainability are not mutually exclusive. JC embraces environmentally responsible manufacturing practices, including:

- Recycling: Re-melting scrap aluminum and wax materials to minimize waste.

- Energy Efficiency: Utilizing advanced furnace technologies that reduce energy consumption.

- Water Conservation: Employing closed-loop cooling and minimal water use systems.

- Emissions Control: Implementing filtration and ventilation to limit air pollutants.

By aligning precision manufacturing with sustainability, JC provides ethical, future-ready solutions for clients who value environmental stewardship alongside technical excellence.

The Impact of Precision on Cost, Lead Times, and Customer Satisfaction

Precision influences not just the technical quality of cast and machined parts, but also the economics of manufacturing. JC’s investments in precision technologies and process optimization yield:

- Lower Defect Rates: Reducing the need for costly rework or replacement.

- Shorter Lead Times: Streamlining production and enabling rapid fulfillment.

- Cost Efficiency: Minimizing scrap and maximizing yield for competitive pricing.

- Enhanced Customer Satisfaction: Delivering consistent results builds trust and long-term partnerships.

JC’s approach results in cost savings that can be reinvested into further innovation, benefiting both the company and its customers.

Challenges in Achieving and Maintaining Precision

Despite the many advantages, maintaining precision in aluminum casting foundry manufacturing is not without its challenges. JC must continually address:

- Thermal Distortion: Managing the effects of temperature fluctuations on part geometry.

- Complexity in Tooling: Designing and maintaining molds that can withstand repeated cycles without degradation.

- Skill Retention: Ensuring operators and engineers remain highly trained and motivated.

- Process Variation: Controlling all variables to prevent unforeseen deviations.

JC overcomes these hurdles through vigilant monitoring, robust training programs, and ongoing investment in research and development.

Customer Collaboration: Driving Precision Through Partnership

Precision casting and machining at JC is a collaborative endeavor. Early engagement with customers enables JC to anticipate design challenges, propose manufacturability improvements, and align specifications with production realities. By fostering open communication and iterative feedback, JC ensures that every project delivers optimal results, saving time and resources for all involved.

Future Trends in Precision Aluminum Casting

The future of aluminum casting foundry manufacturing is poised for further transformation as precision is augmented by digitalization, artificial intelligence, and additive manufacturing. JC is at the vanguard of these trends, piloting new approaches such as:

- Digital Twins: Creating virtual replicas of casting operations for predictive analytics and process optimization.

- Smart Sensors: Embedding IoT devices to monitor equipment health and process stability in real time.

- Hybrid Manufacturing: Combining investment casting with additive techniques to unlock unprecedented design freedom.

- Machine Learning Algorithms: Leveraging historical data to drive continuous improvement in quality and efficiency.

These innovations promise to further enhance precision, flexibility, and sustainability for JC and its customers, redefining the limits of aluminum casting foundry manufacturing.

Summary Table: JC’s Precision Transformation

| Aspect | JC’s Approach | Impact |

|---|---|---|

| Process Control | Automated monitoring and rigorous protocols | Consistent quality and reduced defects |

| Technology | CAD, robotics, NDT, CNC machining | Enhanced dimensional accuracy and performance |

| Quality Assurance | Comprehensive inspection and documentation | Reliability and customer trust |

| Sustainability | Recycling, energy efficiency, emissions control | Environmental responsibility |

| Customer Collaboration | Early engagement and feedback loops | Optimized design and manufacturing outcomes |

Tags:aluminum investment casting,carbon steel casting,valve casting,medical investment casting