Duplex stainless steel investment casting technology is revolutionizing the manufacturing landscape for industries requiring components with exceptional mechanical properties and corrosion resistance. JC, a premier investment casting and machining manufacturer, leverages the unique dual-phase structure of duplex stainless steels to deliver parts that combine the best features of austenitic and ferritic grades: high strength, excellent corrosion resistance, and greater toughness. The investment casting process allows JC to manufacture intricate, lightweight, and high-precision components with minimal material waste.

This synergy brings significant economic advantages, such as reduced raw material use, lower maintenance needs, and decreased production costs for complex geometries. Industries like oil & gas, chemical processing, water treatment, and power generation benefit from longer-lasting, more reliable components that withstand aggressive environments. JC’s robust quality assurance and advanced machining capabilities ensure every part meets stringent specifications.

Sustainability is also a key benefit, as duplex alloys require fewer alloying elements and the casting process supports recycling and energy efficiency. JC overcomes technical challenges related to heat treatment and phase balance using state-of-the-art process controls and metallurgical expertise. As the technology evolves, JC continues to invest in R&D, positioning itself at the forefront of innovation in duplex stainless steel investment casting.

As a leading investment casting and machining manufacturer, JC is committed to delivering advanced solutions for demanding industrial sectors. Among the most exciting developments in modern metallurgy is the adoption of duplex stainless steel in investment casting. At JC, we have seen firsthand how this combination transforms product performance, cost-efficiency, and reliability. In this article, we delve deeply into the unique benefits of duplex stainless steel investment casting technology, drawing upon our extensive expertise and real-world experience to illustrate why it stands out as a superior option for industries worldwide.

Understanding Duplex Stainless Steel

Duplex stainless steels are a family of grades characterized by a dual-phase microstructure: roughly equal parts austenite and ferrite. This balanced structure offers an exceptional blend of properties – the corrosion resistance of austenitic grades with the strength of ferritic stainless steel. Over the years, JC has utilized duplex grades such as 2205, 2507, and other custom alloys to produce components that exceed client expectations in terms of longevity and mechanical performance.

Key features of duplex stainless steel:

- High resistance to pitting and crevice corrosion

- Excellent stress corrosion cracking resistance

- Superior mechanical strength compared to traditional stainless steels

- Good weldability and formability

- Cost-effective solution for high-performance applications

Investment Casting Process at JC

Precision and Flexibility

Investment casting, also known as lost-wax casting, is a process that enables the creation of highly complex shapes with incredibly tight tolerances. At JC, we have refined this process to take full advantage of duplex stainless steel’s unique properties. The steps include:

undefined

- Design and wax pattern creation

- Wax assembly and shell building

- Dewaxing and preheating

- Metal pouring and solidification

- Shell removal and cleaning

- Final machining (if required)

This method allows for freedom in design, significant material savings, and the ability to produce thin-walled, intricate geometries that would be challenging or impossible to achieve with traditional manufacturing techniques.

The Synergy: Why Duplex Stainless Steel for Investment Casting?

Material Performance

Combining duplex stainless steel with investment casting technology multiplies the advantages of both. Components produced by JC using this synergy exhibit enhanced mechanical and chemical properties, leading to increased durability and lower lifecycle costs. Duplex stainless steel’s superior strength means thinner sections can be cast without compromising structural integrity, resulting in weight reduction and material efficiency.

Corrosion Resistance in Critical Applications

Industries such as oil & gas, chemical processing, and marine engineering demand materials that can withstand aggressive environments. Duplex stainless steel investment castings, manufactured at JC, are especially suited for:

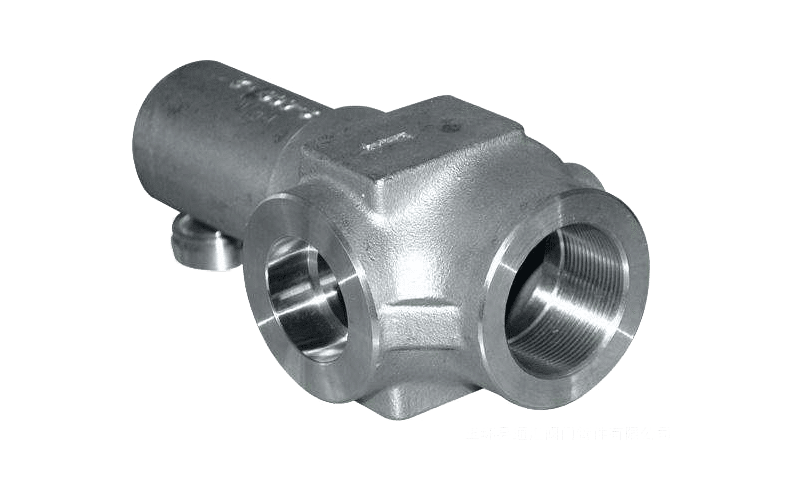

- Pumps and valves exposed to seawater or brine

- Heat exchangers handling chloride-rich fluids

- Offshore platform components

- Impellers and flow control devices

Economic Benefits of Duplex Stainless Steel Investment Casting

JC’s clients enjoy significant economic gains by choosing duplex stainless steel investment casting. Some of these benefits include:

- Reduced raw material use due to high strength-to-weight ratio

- Lower production costs for complex shapes – investment casting minimizes the need for post-casting machining

- Decreased maintenance and replacement expenses owing to superior corrosion and wear resistance

- Improved energy efficiency in applications due to lighter, stronger components

Moreover, the casting process at JC supports both short runs and high-volume production, offering flexibility for both prototyping and mass manufacturing.

Quality Assurance and Machining Excellence at JC

Advanced Inspection and Testing

At JC, every duplex stainless steel investment casting undergoes rigorous inspections. Non-destructive testing (NDT) techniques, including radiography, ultrasonic testing, and dye penetrant inspection, ensure the integrity of each component. Our team guarantees that every part meets or exceeds customer specifications and global standards.

State-of-the-Art Machining Capabilities

After casting, certain parts require secondary machining for precise fits or functional surfaces. JC is equipped with a full suite of CNC machines, lathes, milling centers, and finishing tools. We maintain tight dimensional tolerances and surface finishes, offering our clients turnkey solutions from raw casting to finished product.

Sustainability and Environmental Impact

As sustainability becomes increasingly important, JC is proud that duplex stainless steel investment casting supports greener manufacturing. Duplex alloys require less alloying additions than super austenitic grades, reducing resource consumption. The investment casting process itself generates minimal waste, as wax patterns can be recycled and scrap metal is easily reprocessed.

Key Sustainability Advantages:

- Lower energy consumption during processing and use

- Longer service life, reducing overall environmental footprint

- Supports circular economy through material recyclability

Applications Across Diverse Industries

Oil & Gas

Duplex stainless steel investment castings from JC are integral to the reliability of subsea and topside equipment. Their resistance to corrosion and high pressure makes them ideal for valves, pumps, and connectors exposed to harsh marine environments.

Chemical Processing

JC supplies custom-cast duplex parts for reactors, heat exchangers, and process piping, where resistance to acidic and caustic chemicals is essential for safety and efficiency.

Water Treatment

Municipal and industrial water treatment plants trust JC’s duplex castings for critical components that must resist chlorides and other corrosive agents over long periods with minimal maintenance.

Power Generation

From turbine components to structural supports, JC’s duplex investment castings deliver mechanical strength and corrosion resistance in both conventional and renewable energy sectors.

Case Studies: JC’s Success Stories

Subsea Valve Assemblies

For an offshore client, JC engineered a series of duplex stainless steel valve bodies and trims. Through investment casting, intricate internal passages were produced that would be impossible with machining alone. The result was a lighter, more robust assembly with a service life exceeding the client’s expectations.

Custom Pump Impellers

In a chemical processing plant, JC’s duplex stainless steel impellers delivered enhanced abrasion and corrosion resistance, reducing downtime and maintenance intervals. The investment casting process allowed for advanced blade geometries, improving pump efficiency.

Technical Challenges and JC’s Solutions

While the combination of duplex stainless steel and investment casting is powerful, it brings technical challenges. Duplex alloys are sensitive to heat treatments and must be carefully controlled to preserve their balanced microstructure. JC’s metallurgical team employs controlled cooling and solution annealing to ensure optimal phase distribution and eliminate undesirable intermetallic phases.

- Optimized gating and venting design to ensure defect-free castings

- Strict temperature control during melting and pouring

- Advanced quality monitoring throughout the process

Through ongoing R&D, JC continues to push the boundaries of what is possible with duplex stainless steel investment castings, opening new frontiers for our clients.

Future Prospects: Innovation and Expansion

The future of duplex stainless steel investment casting is bright, with ongoing advances in alloy chemistry, casting simulation, and digital manufacturing. JC invests heavily in technology upgrades, staff training, and collaborative partnerships to lead the industry into the next era. By embracing additive manufacturing, real-time process monitoring, and data-driven optimization, JC aims to provide even more efficient, high-quality duplex castings for evolving industry needs.

Clients seeking to gain a competitive edge through superior material performance, design flexibility, and sustainability will find that JC’s approach to duplex stainless steel investment casting delivers measurable results today – and promises even greater rewards tomorrow.