How Investment Casting Works for Precision Components

Investment casting is a careful process to make detailed parts, and utilizing an investment casting service can enhance this process. It starts with a wax model, which helps create exact molds. This method allows makers to create tricky shapes that other methods can’t easily achieve.

The importance of investment casting in today’s factories is clear.

- The world’s investment casting market was worth $15.70 billion in 2022.

- Experts expect the market to grow by 4.5% each year soon.

- Aerospace and car industries are big users of investment casting services.

Investment casting is key for making strong, light parts needed in modern production.

Key Takeaways

- Investment casting makes exact parts by using a wax model. This creates molds for detailed designs that other methods can’t do.

- It is important in industries like airplanes and cars. These need strong, light parts for better performance and safety.

- Investment casting is very accurate, with errors as small as 0.075 mm. This means parts often don’t need extra work after casting.

- This method uses less material and helps the environment. It is a smart choice for today’s factories.

- New tools like 3D printing make investment casting even better. They help create tricky shapes faster and more easily.

What is Investment Casting?

Definition and Purpose

Investment casting, also known as lost-wax casting, is a way to make exact parts with little extra work. It starts with a wax model that creates a mold. This mold is filled with melted metal to make the final part. As noted by ScienceDirect, this method is great for making parts with smooth surfaces and tricky shapes. It works best for small batches where other methods might not be as good.

The goal of investment casting is to create accurate parts that meet strict size rules. It’s widely used in industries like aerospace and cars, where precision and dependability are very important.

Key Characteristics

Investment casting has special features that make it stand out. Here are some key points:

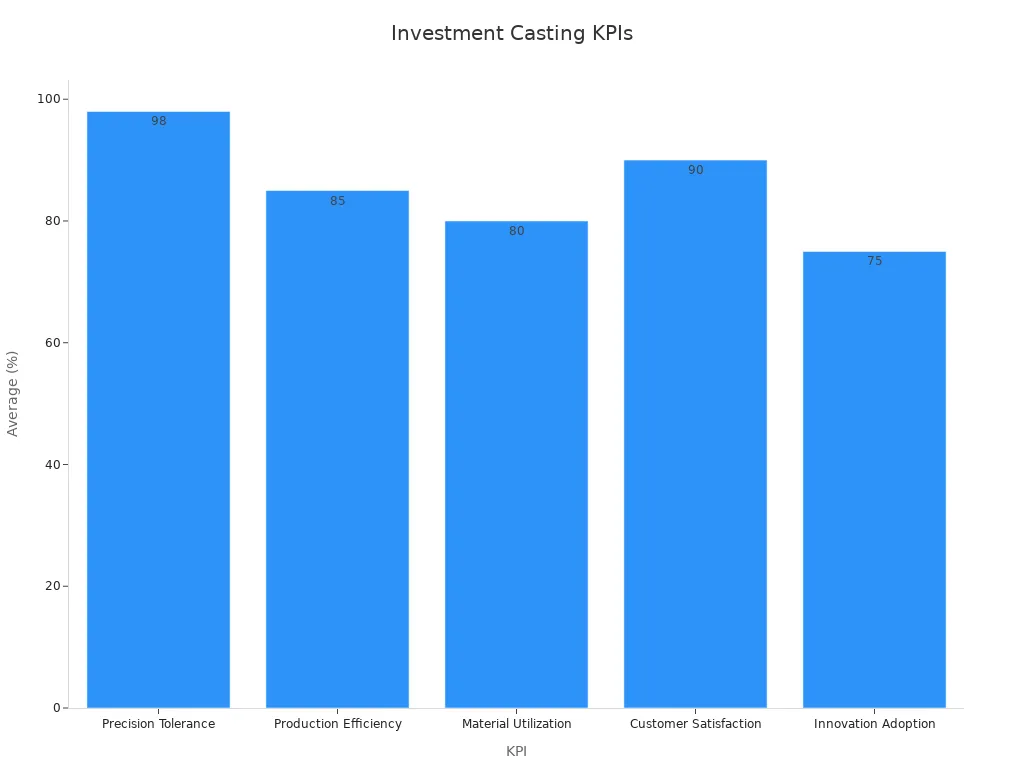

| KPI | Description | Average |

|---|---|---|

| Precision Tolerance | Makes sure parts meet exact size standards. | 98% |

| Production Efficiency | Tracks time and process improvements. | 85% |

| Material Utilization | Cuts waste and supports eco-friendly practices. | 80% |

| Customer Satisfaction | Measures repeat orders and good reviews. | 90% |

| Innovation Adoption | Shows use of new technologies. | 75% |

This method can make detailed shapes and hollow spaces that others can’t. For example, it’s great for creating parts that need little or no extra shaping.

Importance in Manufacturing

Investment casting is very important in today’s factories. It makes strong, light parts that are needed in industries like aerospace, cars, and medical tools. For example, the aerospace industry uses it to make air ducts and engine parts that need to be both strong and precise.

The global market for investment casting is expected to grow from USD 16.51 billion in 2024 to USD 25.39 billion by 2033, with a yearly growth rate of 4.9%. This shows more industries are using it. New technology and eco-friendly methods are also making it better and more popular.

Using an investment casting service helps you get top-quality parts while wasting less material. It’s a smart and green choice for making precise parts.

Step-by-Step Process of Investment Casting

Pattern Creation

The first step is making a detailed wax model. This model matches the shape of the final part. It must account for shrinking when the metal cools. This ensures the final piece is the right size.

New tools like 3D printers make this step easier. They help create very detailed wax models with great accuracy. After making the wax models, they are joined into a tree-like shape. This “wax tree” lets you cast many parts at once, saving time.

Tip: Use 3D printers for better results, especially for tricky designs.

Mold Preparation

Next, the wax tree is used to make the mold. You dip it into a liquid ceramic mix to coat it. Then, sprinkle fine sand over it to make it stronger. This is done several times to build a thick, strong shell.

The ceramic shell must dry fully before moving on. Drying helps the mold keep its shape and handle hot metal. Controlling the drying process prevents cracks or weak spots in the mold.

Wax Removal

After the mold is ready, the wax is removed. The wax tree is heated in a special oven, melting the wax. This leaves an empty ceramic mold. Removing all the wax is very important for a good final product.

The ceramic mold is then fired at high heat to harden it. This makes it strong enough to hold the melted metal. Heating the mold also reduces the chance of cracks during casting.

Note: Removing wax and firing the mold are key steps. Skipping them can cause problems in the final part.

By following these steps, you can make a perfect mold. This process is used in industries needing detailed designs and high-quality parts. It’s a key method in modern manufacturing.

Metal casting

Once the ceramic mold is ready, molten metal is poured inside. The metal is heated until it melts completely. This helps it flow into every tiny detail of the mold.

The temperature of the molten metal must be carefully controlled. If it’s too hot, the mold can break. If it’s too cold, the mold won’t fill properly. Precision is very important in this step.

Tip: Use sensors to check the metal’s temperature. This helps avoid mistakes and keeps results consistent.

After pouring, the metal cools and hardens. Cooling time depends on the metal type and part size. When the metal is solid, the ceramic mold is broken off. This reveals the rough cast part.

Post-processing

Post-processing is the last step in investment casting. It makes sure the part meets quality standards and works as needed.

- Removing extra material: After breaking the mold, leftover pieces like sprues are cut off. Tools like saws or grinders are used for this.

- Smoothing surfaces: The part may feel rough. Sandblasting or polishing makes it smooth and removes flaws.

- Heat treatment: Some parts need heating to make them stronger. They are heated and cooled in a controlled way to improve durability.

- Checking for defects: The part is inspected for problems like cracks. Tests like X-rays or ultrasonic scans ensure it’s safe to use.

Note: Post-processing is very important for high-quality parts. Skipping this step can cause parts to fail when used.

By following these steps, you can create precise parts for industries like aerospace, cars, and medical tools. Using an investment casting service makes the process easier and ensures great results.

Materials Used in Investment Casting

Common Metals and Alloys

Investment casting uses many metals and alloys for different needs. Each material has special features that suit specific uses. Here are some popular choices:

- Copper Alloys: These are strong and resist rust. They also conduct electricity well. They are used in musical instruments, plumbing parts, and electrical items.

- Cast Iron: This is cheap and precise. It’s common in car parts and home appliances. Gray iron reduces vibration, while ductile iron is very strong.

- Low Alloy Steel: This combines strength and toughness. It’s great for aerospace and car industries.

- Aluminum Alloys: These are light but strong. They work well in car parts and electronics.

- Carbon Steel: This is affordable and easy to shape. It’s often used in electric motors and transformers.

- Super Alloys: These are very strong and handle heat well. They are used in aerospace and nuclear fields.

Tip: Pick an alloy based on your product’s needs, like strength or rust resistance.

Material Suitability

The right material depends on how it performs in certain conditions. For example, stainless steel is strong and resists rust. This makes it perfect for food tools, medical devices, and boats.

The table below shows how investment casting compares to other methods for material performance:

| Casting Method | Surface Quality | Microstructure Type | Tensile Strength | Fatigue Performance |

|---|---|---|---|---|

| Investment Casting | Smoother, more precise | Coarse equiaxed grains | Moderate | Moderate |

| Selective Laser Melting | Rougher, less precise | Fine dendritic structure | Higher | Superior |

Investment casting cools slower, creating a rougher microstructure. This can lower its strength. But it makes very smooth surfaces and detailed designs, which are great for complex parts.

Factors Influencing Selection

Choosing the right material for investment casting depends on several things:

- Mechanical Properties: Strength and toughness are important for parts under stress.

- Corrosion Resistance: Materials like stainless steel are best for tough environments.

- Cost: You need to balance price and performance. Carbon steel is a cheap option.

- Application Requirements: Superalloys are needed for high heat, while aluminum is good for lightweight needs.

- Manufacturing Complexity: Some materials need advanced methods to ensure quality.

By thinking about these factors, you can pick the best material for your project. This helps make sure the final product works well and stays within budget.

Advantages and Disadvantages of Investment Casting

Key Advantages

Investment casting has many benefits for making precise parts. It can create intricate shapes as one solid piece. This removes the need for assembly, saving time and avoiding weak spots. The process also ensures great size accuracy, with tolerances as small as 0.075 mm. This means parts fit perfectly without extra shaping.

Another big plus is the smooth surface finish. Parts made this way often don’t need polishing or sanding. Thin sections, as narrow as 0.40 mm, can be made without flaws. This makes it perfect for lightweight designs. You can also use many different materials, giving you options to match your needs.

The method is also good for the environment. The wax used to make patterns can often be reused, cutting down on waste. Less extra shaping means you save both time and money during production.

Key Disadvantages

However, investment casting has some downsides. The process has many steps, which can make it cost more than other methods. The tools and molds needed are expensive, so it’s best for making large numbers of parts.

It’s also tricky to make parts with small holes or hollow spaces. This limits the designs you can create. The materials and tools for investment casting are pricey, which might not work for all budgets.

The table below shows the main pros and cons:

| Advantages of Investment Casting | Disadvantages of Investment Casting |

|---|---|

| Complex shapes can be made as one solid part. | Many steps make it more costly than other methods. |

| Thin sections, as small as 0.40 mm, are possible. | High mold costs make it better for large batches. |

| Excellent size accuracy with tolerances of 0.075 mm. | Materials and tools are expensive. |

| Smooth surfaces often don’t need extra finishing. | Hard to make parts with small holes or hollow areas. |

| Works with many types of materials. | |

| Saves time and money by reducing extra shaping. | |

| Wax can be reused, reducing waste. |

Knowing these pros and cons can help you decide if this method fits your project.

Applications of Investment Casting Service in Modern Manufacturing

Investment casting is important in making strong, precise parts. It is used in industries like aerospace, cars, and medical tools. Below are examples of how it helps these fields.

Aerospace Components

Investment casting is key in making airplane parts. It creates light, strong pieces that meet strict rules. Examples include turbine blades and engine parts. These must handle high heat and pressure without breaking.

- The aerospace industry may grow by 4.5% yearly until 2028.

- This method ensures parts are safe and work well.

- Lighter parts help planes use less fuel, which is greener.

This process also allows for creative designs in aerospace. It makes tricky shapes that other methods can’t. For example, turbine blades with cooling paths improve engines.

Tip: Use investment casting for tough, precise parts in harsh conditions.

Automotive Parts

In cars, investment casting makes strong, light parts. These improve how cars perform and save fuel. Parts like brakes, engines, and gearboxes are made this way.

New technology has made this process better for car-making. Tools like AI ensure parts are high quality and cut costs. This also reduces waste, helping the planet.

This method works well with materials that resist rust. Aluminum is great for light parts, while stainless steel lasts longer in tough spots.

Note: Investment casting is great for car parts needing strength and reliability.

Medical Devices

Medical tools need to be very precise and safe. Investment casting is perfect for making surgical tools, implants, and machines.

This method creates detailed designs with smooth surfaces. This lowers the chance of germs sticking. Strong materials like titanium and stainless steel are often used. These last long and don’t rust.

AI has made this process faster and better for medical needs. It ensures high-quality parts while being eco-friendly. This matches the healthcare focus on sustainability.

Tip: Pick investment casting for medical tools needing precision and safety.

Other industries

Investment casting is useful in many fields besides aerospace, cars, and medical tools. It makes strong, detailed parts for different uses. Let’s look at some industries where this method is very helpful.

Energy Sector

The energy field uses investment casting for power system parts. Examples include turbine blades, pump pieces, and valve bodies. These parts must handle high heat and pressure. This method ensures they are strong and precise.

For green energy, it helps make wind turbine parts and solar mounts. These parts are light but strong, improving performance and cutting costs.

Tip: Energy companies can use investment casting to make better parts.

Defense and Military

The military uses investment casting for weapons and vehicle parts. It creates detailed designs that meet strict rules. Examples include gun parts, missile pieces, and tank tracks.

This method also makes lightweight armor and safety gear. These items need to be strong but not heavy, and investment casting delivers both.

Industrial Machinery

Factories use investment casting for gears, impellers, and machine covers. These parts must last long and work in tough conditions. This process makes them strong and accurate.

It also allows custom designs. You can make parts that fit specific machines, improving how they work and reducing repairs.

Jewelry and Art

Investment casting isn’t just for heavy industries. Jewelers use it to make detailed designs. Artists rely on it for sculptures and decorations.

This method allows creative and precise work. It creates smooth finishes and tricky shapes that other methods can’t.

Food and Beverage

In food production, investment casting makes clean equipment like valves and pumps. These parts must meet strict cleanliness rules. Stainless steel is often used because it doesn’t rust and is easy to clean.

This process creates smooth surfaces, stopping bacteria from growing. It also makes custom parts for specific systems.

Note: Investment casting is great for industries needing clean, strong, and precise parts.

By using investment casting, industries get high-quality parts made for their needs. This method keeps growing and proving its value in many areas.

Comparison with Other Casting Methods

Investment Casting vs. Die Casting

Investment casting and die casting are used for different tasks. Investment casting is great for making detailed shapes with exact sizes. It creates smooth parts that often don’t need extra polishing. Die casting, however, is faster and better for making many parts quickly. It works well when you don’t need perfect accuracy or finishes.

The metals used in each method are also different. Investment casting can use many types of metals, including superalloys. Die casting mainly uses lightweight metals like aluminum and zinc. If you need detailed parts with smooth finishes, investment casting is the best choice. But if you want to make a lot of parts cheaply, die casting is better.

Investment Casting vs. Sand Casting

Investment casting and sand casting have clear differences. Investment casting makes parts with better accuracy and smoother surfaces. Sand casting is cheaper but leaves rough finishes that need more work.

Investment casting can also handle more complex designs. Sand casting struggles with tricky shapes because sand molds aren’t as precise as ceramic ones. If you need detailed, high-quality parts, investment casting is the way to go. But for bigger, simpler parts where cost matters, sand casting works fine.

Unique Benefits of Investment Casting

Investment casting is special because it makes detailed parts with little waste. It offers great accuracy and smooth finishes, making it perfect for industries like aerospace and medical tools. Unlike other methods, it works with many materials, including superalloys and stainless steel.

The table below shows how investment casting compares to other methods:

| Casting Method | Dimensional Accuracy | Surface Finish | Production Efficiency | Complexity in Shapes | Cost |

|---|---|---|---|---|---|

| Investment Casting | High | Excellent | Moderate | High | High |

| Die Casting | Moderate | Good | High | Moderate | Moderate |

| Sand Casting | Low | Fair | Low | Low | Low |

If you need precise, smooth, and complex parts, investment casting is the best. It costs more at first, but its quality and flexibility make it worth it for important projects.

Investment casting is a method that makes very precise parts. It allows for tight size limits, as small as ±0.005 inches. The surfaces are smooth, with finishes of Ra 125 microinches. This process uses materials efficiently, with up to 98% utilization. Less waste means it’s better for the environment.

Industries like healthcare and aerospace rely on investment casting. It helps make safe medical tools and strong airplane parts. Advanced systems check for defects to ensure reliability. New technologies like 3D printing improve this process. They make tricky shapes easier and save money.

Choosing investment casting gives you high-quality parts quickly. It also helps plan production better. Its accuracy and flexibility make it important for modern factories.

FAQ

What industries use investment casting the most?

Investment casting is common in aerospace, cars, medical tools, and energy. It’s also used in defense, jewelry, and food production. This method makes strong, precise parts for high-quality needs.

Can investment casting make tricky designs?

Yes, investment casting is great for detailed shapes and designs. It can create thin walls, hollow spaces, and smooth surfaces. This makes it ideal for designs other methods can’t handle.

Is investment casting good for the environment?

Investment casting reduces waste by reusing wax and saving materials. You can also pick eco-friendly metals and processes, making it a greener choice for factories.

How does investment casting compare to 3D printing?

Investment casting makes stronger parts with smoother finishes than 3D printing. While 3D printing is faster for samples, investment casting is better for making many durable parts.

What metals work best for investment casting?

You can use metals like stainless steel, aluminum, copper alloys, and superalloys. The best choice depends on your needs, like strength or heat resistance.