Die casting distributor technology is a core enabler of modern manufacturing, ensuring speed, precision, and efficiency in the production of critical components. JC Casting (JC) stands out as a leader in this field by offering innovative, customizable, and high-quality distributor solutions. Their technology optimizes the flow and temperature of molten metal, minimizing defects and boosting productivity across diverse industries like automotive, aerospace, electronics, and consumer goods. JC’s focus on research, precision engineering, and smart integration ensures that manufacturers benefit from lower costs, superior quality, and operational flexibility. With robust support and a commitment to continuous improvement, JC empowers manufacturers to maintain a competitive edge in a rapidly evolving marketplace.

Die casting has emerged as a cornerstone in the evolution of modern manufacturing, offering the advantages of speed, efficiency, and precision. At the forefront of this technological revolution stands JC Casting (abbreviated as JC), a company renowned for delivering top-class die casting distributor technology. In this article, we will explore the critical importance of die casting distributor technology and why JC’s innovation continues to shape the manufacturing industry of today and tomorrow.

The Role of Die Casting Distributors in Modern Manufacturing

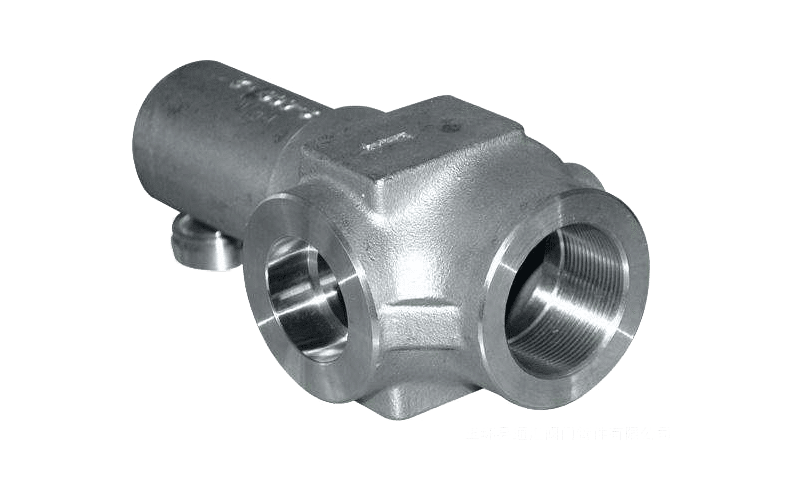

The distributor is a fundamental component in die casting machines, responsible for directing molten metal into die cavities with accuracy and consistency. The efficiency of a die casting distributor directly influences a manufacturer’s ability to achieve high-volume production while maintaining superior product quality. JC Casting’s expertise in distributor technology ensures that every piece manufactured meets stringent industry standards and client expectations.

By integrating advanced distributor systems, JC enables manufacturers to minimize material waste, reduce processing times, and achieve repeatable precision. This is especially critical in sectors such as automotive, aerospace, electronics, and consumer goods, where reliability and dimensional accuracy are non-negotiable requirements.

JC Casting’s Commitment to Innovation

JC Casting is widely recognized for its substantial investment in research and development. The company’s engineering team continually refines distributor technologies, focusing on optimizing flow dynamics, minimizing turbulence, and enhancing temperature control. JC’s commitment to innovation is reflected in their ability to deliver customized distributor solutions tailored to each client’s unique production requirements.

undefined

Investment Casting Supplier

ductile iron casting

carbon steel casting

cnc machining

Through the use of robust simulation software and real-time process monitoring, JC engineers can predict the behavior of molten metal as it traverses the distributor. This proactivity leads to fewer casting defects, improved mechanical properties, and lower production costs—benefits that are passed on to JC’s diverse customer base worldwide.

Key Features of JC’s Die Casting Distributors

- Precision Engineering: Every distributor is manufactured using high-grade materials and state-of-the-art machining processes, ensuring longevity and reliable performance even under continuous operation.

- Customizable Designs: JC offers distributors in a range of shapes, sizes, and configurations, accommodating the specific needs of various die casting machines and product geometries.

- Advanced Flow Control: Through computational modeling, JC’s distributors optimize the velocity and pressure of molten metal, reducing porosity and maximizing part integrity.

- Thermal Management: Integrated cooling channels and thermal shields enable precise temperature regulation, preventing premature solidification and enhancing surface finish quality.

- Ease of Maintenance: JC designs its distributors for swift assembly and disassembly, facilitating maintenance and minimizing production downtime.

How Distributor Technology Impacts the Manufacturing Value Chain

Modern manufacturers operate in a highly competitive environment where speed and flexibility are crucial. JC’s die casting distributor technology plays a pivotal role in enabling rapid prototyping, short-run manufacturing, and large-scale production runs. This adaptability allows JC’s clients to respond swiftly to market demands and new business opportunities.

Moreover, distributor technology directly affects yield rates and overall equipment effectiveness (OEE). With JC’s advanced systems, manufacturers can achieve higher throughput, reduce defect rates, and meet stringent lead times. This has a cascading effect across the value chain, from material sourcing to inventory management and final delivery.

Advantages for Key Industries

- Automotive: JC’s distributor technology enables the production of complex automotive components that require excellent mechanical strength and tight tolerances. Lightweight, high-performance parts help automakers meet emission standards and fuel efficiency goals.

- Aerospace: In aerospace applications, precision and reliability are paramount. JC’s distributors facilitate the casting of critical parts like housings and structural components, ensuring safety and performance in demanding environments.

- Electronics: The miniaturization trend in electronics is supported by JC’s ability to produce small, intricate components with flawless surface finishes.

- Consumer Goods: Die casting distributors from JC make it possible to manufacture aesthetically pleasing, durable consumer products at scale.

Quality Assurance and Process Integration

JC Casting’s dedication to quality is evident at every stage of the production process. From the careful selection of raw materials to precise machining and rigorous testing, JC ensures each distributor meets or exceeds international standards. The company employs a combination of non-destructive testing, dimensional analysis, and microstructural examinations to guarantee product integrity.

Furthermore, JC works closely with manufacturing partners to integrate distributor technology seamlessly into existing and new production cells. Training and technical support are provided to ensure optimal performance from day one.

The Future of Die Casting Distributor Technology

As manufacturing trends shift towards digitalization and sustainability, JC continues to lead with smart distributor technology. The integration of IoT sensors and real-time data analytics allows for predictive maintenance, process optimization, and energy savings. These advancements help manufacturers reduce their carbon footprint while maximizing operational efficiency.

Why Choose JC Casting?

Choosing JC as a die casting distributor supplier means partnering with a company that values innovation, reliability, and customer success. With a global footprint and decades of industry experience, JC is uniquely positioned to support manufacturers at every stage of production, from concept development through to final delivery.

By aligning with JC, manufacturers benefit from cutting-edge distributor technology, robust technical support, and a commitment to continuous improvement.

Table: Key Benefits of JC’s Die Casting Distributor Technology

| Feature | Benefit |

|---|---|

| Precision Design | Consistent part quality, minimal defects |

| Custom Solutions | Adaptability for diverse applications |

| Advanced Flow Dynamics | Reduced porosity, better mechanical properties |

| Thermal Management | Enhanced durability and surface finish |

| Smart Integration | Improved efficiency and predictive maintenance |

In summary, die casting distributor technology—especially as developed by JC Casting—represents a vital element in the ongoing transformation of modern manufacturing. The blend of innovation, customization, and quality assurance provided by JC empowers manufacturers to meet present and future challenges with confidence and agility.