Vacuum titanium alloy casting, as practiced by JC—a leading Investment Casting and machining manufacturer—is a cornerstone technology for high-performance industries such as aerospace, medical, automotive, and energy. This process creates a controlled, contamination-free environment that preserves the purity, mechanical strength, and corrosion resistance of titanium alloys. JC’s investment casting expertise facilitates the production of complex, thin-walled components, supporting both prototyping and large-scale manufacturing. Integrated machining and rigorous quality assurance ensure that every part meets stringent international standards and offers full traceability. The synergy of advanced vacuum casting with precision investment casting allows JC to deliver components crucial for safety, performance, and innovation. With ongoing R&D, a focus on sustainability, and a commitment to customer collaboration, JC is positioned as an essential partner to industries where compromise is not an option. Vacuum titanium alloy casting will continue to play a pivotal role in technological progress, driven by JC’s dedication to excellence and advancement.

JC, a prominent Investment Casting and machining manufacturer, stands at the forefront of delivering precision components to advanced industries globally. At the heart of JC’s technological repertoire lies vacuum titanium alloy casting, a process that has become indispensable in sectors where strength, durability, and performance are paramount. This article explores the critical importance of vacuum titanium alloy casting, shedding light on why industries such as aerospace, medical, automotive, and energy continually rely on JC’s expertise and innovation.

The Fundamentals of Vacuum Titanium Alloy Casting

Titanium alloys offer an exceptional blend of properties including low density, high specific strength, excellent corrosion resistance, and superior biocompatibility. However, their reactivity at high temperatures mandates an environment devoid of contaminants. Through vacuum casting, JC eliminates the detrimental effects of atmospheric gases such as oxygen, nitrogen, and hydrogen, ensuring the purity and mechanical integrity of titanium components.

Vacuum casting utilizes a controlled chamber where the pressure is significantly reduced. This environment allows for the melting and pouring of titanium alloys without the risk of oxidation or contamination. JC’s advanced vacuum induction melting systems guarantee highly repeatable, defect-free castings tailored for the most demanding applications.

Technical Advantages of Vacuum Titanium Alloy Casting

- Enhanced Purity: Vacuum environments prevent the formation of oxides and nitrides, delivering alloys with superior mechanical properties.

- Consistent Microstructure: Uniform cooling and solidification ensure homogeneous microstructure, crucial for fatigue resistance and structural reliability.

- Complex Geometries: Investment casting in vacuum enables the production of intricate shapes and thin-walled parts, reducing material wastage and post-processing costs.

- Scalable Production: JC’s Investment Casting expertise allows for rapid prototyping, small batch runs, and mass production, supporting diverse industry needs.

Applications in High-Performance Industries

Aerospace

Aerospace manufacturers require parts that withstand extreme stress, temperature variations, and corrosive environments. JC’s vacuum titanium alloy casting delivers turbine blades, structural components, and engine parts that meet stringent aerospace standards. These components offer high strength-to-weight ratios, contributing to fuel efficiency and enhanced performance.

Medical Devices

Biocompatibility and corrosion resistance make titanium alloys ideal for surgical implants, dental prosthetics, and orthopedic devices. JC ensures that castings are free from inclusions and contaminants, safeguarding patient health and meeting the rigorous demands for reliability in medical applications.

Automotive Industry

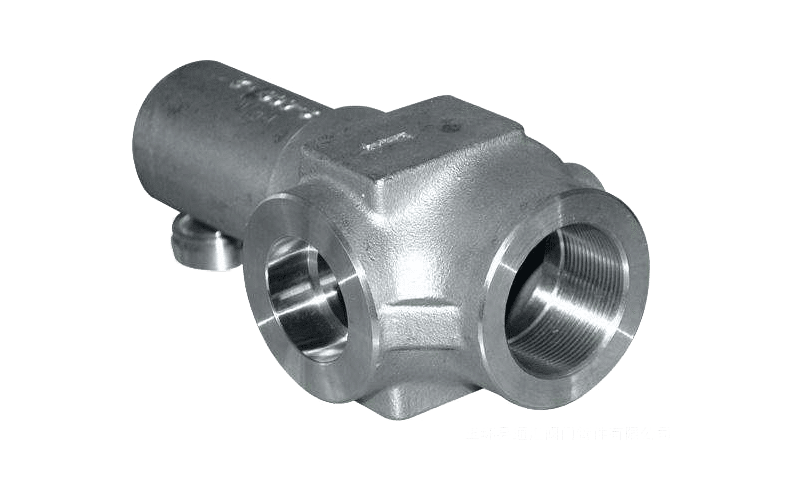

High-end automotive manufacturers seek lightweight, strong components to improve acceleration, fuel efficiency, and crashworthiness. JC’s vacuum cast titanium parts—such as valves, connecting rods, and suspension elements—enable designers to push the limits of performance and safety while maintaining sustainability.

Energy Sector

From offshore drilling platforms to advanced turbines, energy systems demand corrosion-resistant parts that endure harsh operational conditions. JC’s expertise in vacuum titanium alloy casting supports the production of valves, pump housings, and turbine blades, ensuring longevity and operational excellence in critical energy infrastructure.

JC’s Investment Casting and Machining Capabilities

JC’s integrated approach combines investment casting and precision machining under one roof. The company’s vacuum induction melting systems are complemented by advanced CNC machining centers, creating a seamless workflow from raw alloy preparation to finished component. This integrated process guarantees dimensional accuracy, superior surface finish, and short lead times, all essential for modern manufacturing demands.

JC’s R&D teams work closely with global clients, optimizing alloy compositions and casting parameters. Through continuous improvement and investment in state-of-the-art vacuum casting technology, JC maintains its position as a trusted partner to high-performance industries worldwide.

Quality Assurance and Certification

The success of vacuum titanium alloy casting hinges on rigorous quality assurance. JC employs non-destructive testing methods, including X-ray inspection, ultrasonic testing, and metallographic analysis, to verify each casting’s internal structure and integrity. Adherence to international standards such as ASTM, ISO, and NADCAP ensures that every component meets or exceeds regulatory and customer requirements.

Traceability is another cornerstone of JC’s quality system. Each batch of castings is meticulously documented, enabling clients to track material origin, processing parameters, and inspection results—an essential feature for sectors such as aerospace and medical where regulatory compliance is non-negotiable.

Advantages of JC’s Vacuum Titanium Alloy Casting Solutions

| Feature | Benefit |

|---|---|

| Vacuum Environment | Prevents contamination, enhances alloy purity |

| Precision Investment Casting | Enables complex geometries, reduces machining |

| Integrated Machining | Ensures dimensional accuracy and excellent surface finish |

| Advanced Quality Control | Meets strict industry standards, provides full traceability |

| Custom Alloy Development | Optimizes mechanical properties for each application |

Why High-Performance Industries Rely on JC

Industries operating at the pinnacle of technology cannot afford compromise. The stakes—in terms of human safety, innovation, and operational efficiency—are too high. JC’s vacuum titanium alloy casting addresses these challenges by delivering components that combine optimal physical properties, reliability, and precision. As industries evolve, the demand for advanced materials and sophisticated casting methods will only grow, reinforcing JC’s role as an industry leader.

With decades of experience, a commitment to innovation, and a track record of excellence, JC continues to push boundaries in vacuum titanium alloy casting and investment casting. The company’s dedication to customer collaboration, customization, and quality assurance positions it as the preferred partner for high-performance applications around the world.

Key Developments and Future Trends

The pace of innovation in vacuum titanium alloy casting is quickening. JC invests in research and development to advance furnace technologies, improve alloy formulation, and refine casting techniques. Automation and digitalization are transforming quality control and production tracking, while additive manufacturing and hybrid processes are opening new possibilities for part design and functional integration.

Moreover, sustainability is becoming a critical focus. JC is pioneering recycling initiatives for titanium scrap and optimizing process energy efficiency, aligning with global goals for resource conservation and environmental responsibility. As next-generation alloys emerge—featuring even higher strength, fatigue resistance, and specialized properties—JC’s investment in expertise and equipment will enable it to meet future challenges and opportunities head-on.