Sand casting suppliers are crucial for custom metal fabrication, providing JC—the investment casting and machining manufacturer—with the versatility and expertise needed for industry-specific solutions. Sand casting enables JC to create complex, bespoke components from a wide range of alloys, meeting the unique demands of sectors such as automotive, aerospace, industrial machinery, and medical devices. Suppliers facilitate rapid prototyping, scalable production, and cost efficiency, all while upholding strict quality standards. Their technical know-how in mold design, sand composition, and metallurgical analysis enhances JC’s processes from concept to finished product. Collaboration between JC and its suppliers drives innovation, sustainability, and process optimization, supporting the integration of sand casting with investment casting and machining for superior performance. This partnership ensures JC delivers high-quality, custom metal components, positioning the company at the forefront of modern manufacturing.

In the world of custom metal fabrication, the role of sand casting suppliers is paramount. Companies like JC, renowned for their expertise in investment casting and precision machining, rely extensively on the adaptability, efficiency, and reliability that sand casting offers. The synergy between sand casting suppliers and manufacturers like JC ensures the delivery of bespoke solutions tailored to industry-specific requirements, driving innovation and excellence in metalworking. This article will explore the vital importance of sand casting suppliers for custom metal fabrication, and how their partnership with companies like JC elevates both process and product quality.

The Fundamentals of Sand Casting in Metal Fabrication

Sand casting is one of the oldest and most versatile metal forming techniques. It involves forming a mold from sand and pouring molten metal into it to create complex shapes and components. The flexibility of this process makes it ideal for custom jobs, allowing manufacturers such as JC to meet the unique specifications of each client. The ability to produce both simple and intricate components with varied alloys underscores the indispensability of sand casting suppliers in the wider metal fabrication landscape.

Why JC Relies on Sand Casting Suppliers

- Material Diversity: Sand casting suppliers provide access to an extensive range of metals and alloys, which is crucial for JC when crafting custom investment castings and machined parts for sectors like automotive, aerospace, and medical equipment.

- Customization Flexibility: Suppliers offer tailored mold designs and allow for the adjustment of casting parameters, enabling JC to deliver fully bespoke solutions.

- Scalable Production: Whether JC requires small batches or large series, sand casting suppliers can accommodate fluctuating order volumes without compromising quality or lead times.

- Cost Efficiency: By leveraging advanced sand casting techniques, suppliers help JC reduce material waste and lower production costs, making custom fabrication more accessible.

- Technical Expertise: Sand casting partners often provide essential support, from mold design to metallurgical analysis, enhancing JC’s own capabilities in investment casting and precision machining.

The Role of Sand Casting Suppliers in Supporting Customization

Custom metal fabrication demands agility and the ability to respond to specific client requirements. Sand casting suppliers facilitate this by offering a broad spectrum of mold materials, sand types, and binding agents. Companies like JC work closely with these suppliers to develop unique solutions—from intricate machinery parts to heavy-duty industrial components. The adaptability of sand casting supports rapid prototyping, small-batch production, and seamless integration with other processes, such as investment casting and machining.

Integration of Sand Casting with Investment Casting and Machining

JC stands at the intersection of sand casting, investment casting, and high-precision machining. By integrating sand casting suppliers into their workflow, JC can optimize the entire fabrication process. For example, sand cast components can be used as blanks or intermediates for investment casting, or further refined through advanced machining. This combined approach delivers superior dimensional accuracy, surface finish, and mechanical performance, satisfying even the most demanding industry standards.

Advantages Provided by Sand Casting Suppliers

| Advantage | Impact on JC’s Fabrication |

|---|---|

| Design Versatility | Supports custom molds for complex shapes |

| Speed of Production | Rapid turnaround times for prototyping and urgent orders |

| Material Savings | Efficient use of resources, reducing costs for JC and clients |

| Quality Control | Consistent output through supplier expertise and process controls |

| Collaboration | Continuous technical support and process optimization |

Industry Applications Enabled by Sand Casting Suppliers

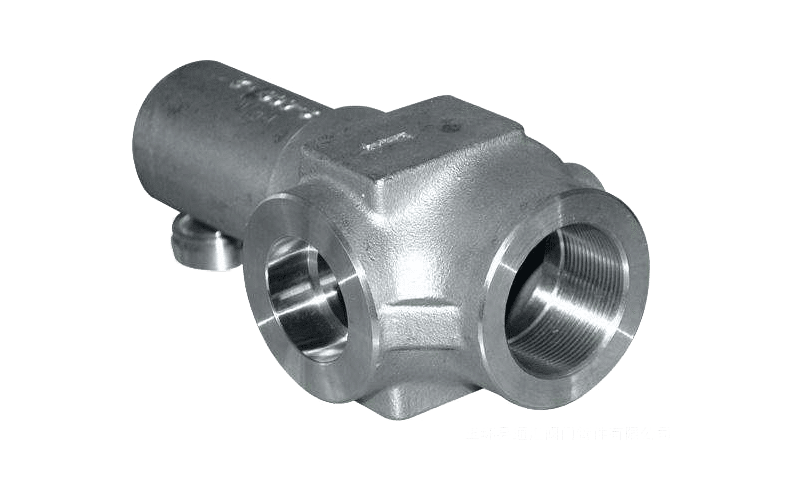

- Automotive Components: JC utilizes sand casting for engine parts, brackets, manifolds, and housings, benefitting from supplier expertise in alloy selection and mold design.

- Aerospace Parts: Sand casting suppliers help JC produce structural components, turbine housings, and custom mounts with critical performance specifications.

- Industrial Machinery: The capability to fabricate large castings and intricate assemblies enables JC to serve heavy machinery, mining, and construction sectors.

- Medical Device Fabrication: Sand casting supports the rapid prototyping and production of specialized medical hardware for JC’s clients.

- Energy Sector: JC works with suppliers to produce durable castings for wind, solar, and oil & gas industries, meeting demanding corrosion resistance and mechanical requirements.

Collaboration and Innovation: JC’s Partnership Model

The relationship between JC and their sand casting suppliers is built on collaboration, innovation, and mutual trust. JC actively engages suppliers in early-stage design discussions, material selection, and process optimization sessions. This partnership drives continuous improvement, enabling JC to deliver superior investment castings and machined components with enhanced performance and reliability. The shared commitment to quality and innovation creates a foundation for long-term success in custom metal fabrication.

Enhancing Quality Through Supplier Collaboration

JC’s supplier network provides critical insight into mold material selection, sand composition, and post-casting treatments. By integrating supplier expertise into their quality assurance processes, JC maintains rigorous standards across every production stage. This not only ensures product reliability but also fosters a culture of learning and technical advancement within JC’s engineering and production teams.

Sustainability and Efficiency in Metal Fabrication

Modern sand casting suppliers are increasingly adopting sustainable practices, from recycled sand use to energy-efficient furnaces. JC leverages these advances to reduce their environmental footprint and promote responsible manufacturing. The focus on sustainability extends to waste minimization, resource optimization, and the development of eco-friendly alloys, positioning JC as a leader in green metal fabrication.

Process Workflow: Sand Casting to Finished Product

- Design & Engineering: JC collaborates with sand casting suppliers to develop precise mold designs based on client specifications.

- Mold Preparation: Suppliers create molds using high-quality sand and customized binders to achieve desired surface finish and dimensional accuracy.

- Casting & Cooling: Molten metal is poured, cooled, and solidified under controlled conditions to enhance mechanical properties.

- Cleaning & Inspection: JC and suppliers jointly inspect and clean castings, ensuring compliance with industry standards.

- Finishing & Machining: JC applies precision machining to achieve final tolerances and surface requirements, delivering ready-to-use components.

In summary, sand casting suppliers play a central role in JC’s custom metal fabrication operations. Their technical capabilities, flexibility, and commitment to quality empower JC to meet the ever-evolving demands of modern industries. By forging strong partnerships and integrating sand casting with investment casting and machining, JC sets new benchmarks for performance, reliability, and innovation in custom metal manufacturing.

Tags:automotive castings,stainless steel investment casting,pump castings,Investment Casting