Prototyping is an essential pillar of JC’s success as a leading Investment Casting & Machining manufacturer. The article details how prototyping bridges the gap between design and production by providing early, tangible models that validate design intent, optimize manufacturing processes, and ensure dimensional accuracy. Through 3D printing, CNC machining, and traditional methods, JC creates prototypes that facilitate risk mitigation, cost reduction, and enhanced client collaboration. Real-world case studies from aerospace, automotive, and medical sectors highlight the value of iterative prototyping in achieving superior product performance and faster time to market. Prototyping synergizes with JC’s advanced machining capabilities, ensuring end-to-end quality and innovation. Although challenges exist, such as material differences and added lead times, JC overcomes them through efficient processes and clear communication. As digital technologies and customer expectations evolve, JC remains ahead by investing in next-generation prototyping tools. Ultimately, prototyping is not just a developmental stage for JC—it’s a strategic advantage that guarantees precision, quality, and customer satisfaction in every investment casting project.

Introduction to JC and the Investment Casting Landscape

In the competitive world of advanced manufacturing, JC stands out as a trailblazing Investment Casting & Machining manufacturer. As global markets demand ever-increasing quality and sophistication in metal components, precision and innovation are not mere advantages—they are necessities. Among the arsenal of strategies that JC employs to meet and exceed client expectations, prototyping holds a pivotal position. This article explores why prototyping is integral to the success of precision casting services, particularly highlighting JC’s approach and expertise in leveraging prototypes for Investment Casting and secondary machining.

The Fundamentals of Investment Casting and the Prototype Process

Investment casting, also known as lost-wax casting, is a manufacturing technique that enables the creation of intricate, high-precision metal parts. The process involves creating a wax model, surrounding it with a ceramic shell, melting out the wax, and finally pouring molten metal into the cavity to form the final product. While the method itself is renowned for its precision, the margin for error can be slim, especially when tolerances are tight and the end application is critical. Prototyping bridges the gap between conceptual design and flawless production, ensuring that each step aligns perfectly with design intent and production requirements.

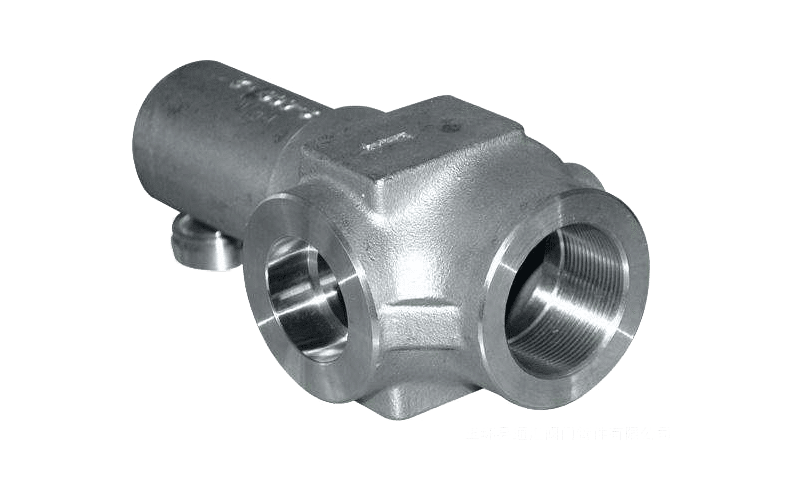

automotive castings

Investment Casting industries served

investment casting tolerance

Role of Prototypes in Precision Casting

The prototype stage provides more than just a physical preview of the final product. For JC, prototyping is indispensable for:

- Design Validation: Quick physical models allow engineers and clients to verify whether the part’s design will perform as required in real-world situations.

- Process Optimization: The prototype acts as a test case, highlighting potential challenges in the wax pattern, shell building, metal pouring, and cooling, allowing process parameters to be adjusted before full-scale production.

- Dimensional Accuracy: Prototypes reveal discrepancies between CAD models and physical components, ensuring critical tolerances are achieved.

- Cost Reduction: Early identification and correction of design or process flaws minimizes expensive rework and wasted materials.

- Customer Collaboration: Tangible prototypes facilitate clear, effective communication between JC and its clients, ensuring mutual understanding and satisfaction.

Prototyping Methods Employed by JC

JC leverages a diverse suite of prototyping techniques to support its investment casting and machining services. Selection of methodology depends on part complexity, desired turnaround time, and material requirements. The most common approaches include:

- 3D Printing: Additive manufacturing technologies such as SLA, SLS, and DLP are used to rapidly create wax or resin patterns for complex geometries, significantly cutting lead times and enabling iterative design changes.

- CNC Machining: For prototypes requiring tight tolerances or metallic properties, JC employs CNC machining to produce samples from actual or similar alloys, allowing for thorough performance testing.

- Traditional Wax Pattern Prototyping: Handcrafted or injection-molded wax patterns remain a reliable choice for certain prototypes, especially where material properties or surface finish are paramount.

Business Advantages of Prototyping in Precision Casting

For JC, the integration of prototyping into the casting workflow translates into tangible business benefits. These advantages extend to both the manufacturer and the client, reinforcing a partnership built on quality and trust. Key benefits include:

- Risk Mitigation: Prototypes help identify and address potential design or process issues before they escalate into costly production setbacks.

- Time Efficiency: The iterative cycle of prototyping and feedback accelerates the design-to-production timeline by ironing out kinks early in the process.

- Enhanced Innovation: Prototyping empowers JC’s engineers to experiment with new alloys, geometries, or functional features without the pressure of full-scale commitment.

- Market Responsiveness: The ability to rapidly prototype enables JC to adapt quickly to changing customer demands or industry trends, maintaining a competitive edge.

- Quality Assurance: Early physical samples serve as benchmarks for future production runs, fostering consistency and reliability.

Case Studies: JC’s Prototyping in Action

JC’s commitment to prototyping has yielded impressive results across diverse industries, from aerospace and automotive to medical devices and energy. Consider the following examples:

- Aerospace Component: A customer required a lightweight, high-strength component with complex internal channels. JC developed several iterations of the prototype using 3D printing, allowing both design optimization and functional testing. The final production run achieved zero defects and exceeded performance expectations.

- Automotive Turbocharger Housings: For a major automotive OEM, JC used CNC-machined prototypes to validate fit, flow, and mechanical properties before committing to full-scale investment casting. This mitigated risk and shortened the time to market.

- Medical Implants: Precision and biocompatibility are paramount in medical applications. Through prototyping, JC was able to fine-tune the surface finish and dimensional tolerances, ensuring both safety and regulatory compliance.

Prototyping and Machining: The Synergistic Value

Prototyping does not exist in isolation at JC. Instead, it’s intricately linked with state-of-the-art machining capabilities. After initial prototypes are created, secondary machining processes such as milling, drilling, and surface finishing are employed to achieve the required geometries, tolerances, and aesthetics. This integrated approach allows JC to:

- Refine Prototypes: Machining of cast prototypes allows for additional adjustments and perfection before full-scale casting.

- Validate Full Manufacturing Workflow: By simulating the entire production sequence, including machining, JC ensures that the final process is robust and repeatable.

- Offer End-to-End Solutions: Clients benefit by receiving not only cast parts but also fully finished assemblies, ready for immediate application.

Challenges in Prototyping for Precision Casting and JC’s Solutions

While prototyping delivers clear advantages, it is not without its challenges. Some common hurdles include:

- Material Differences: Prototype materials (e.g., resin or wax) may not perfectly replicate the properties of final cast metals. JC addresses this by supplementing prototyping with simulations and predictive modeling.

- Cost Management: Prototyping adds a layer of expense, but JC mitigates this through efficient, rapid prototyping techniques and scalability in production transitions.

- Lead Time: Even with rapid processes, prototyping can extend project timelines. JC balances speed with quality assurance through parallel process planning and advanced scheduling tools.

How JC’s Prototyping Empowers Customer-Centric Solutions

At JC, the prototyping process is designed with the customer in mind. From initial consultation through final validation, JC’s team maintains transparent communication, soliciting feedback and making iterative adjustments to ensure the final product precisely matches customer expectations. The collaborative journey is typically structured as follows:

- Requirement Gathering: JC works closely with clients to understand application needs, performance criteria, and cost considerations.

- Concept Prototyping: Early-stage models are produced for conceptual validation, allowing for design tweaks and alignment.

- Functional Testing: Prototypes are subjected to real-world testing and simulation to validate function and durability.

- Production Transition: Once a prototype is approved, JC seamlessly transitions to full-scale casting and machining, preserving lessons and refinements from the prototype stage.

Looking Forward: The Future of Prototyping in Precision Casting at JC

The landscape of precision casting is evolving rapidly, with new materials, processes, and digital technologies reshaping how manufacturers like JC operate. Prototyping remains at the center of this transformation. JC continues to invest in advanced prototyping tools—such as digital twin simulations, hybrid manufacturing platforms, and AI-driven process optimization—to further shorten development cycles, enhance customization, and deliver smarter, higher-performing cast components. With a steadfast commitment to innovation, JC ensures its prototyping services stay ahead of customer needs and industry trends.

Summary Table: The Impact of Prototyping in JC’s Precision Casting Workflow

| Benefit | Description |

|---|---|

| Design Validation | Early physical models confirm design intent and performance |

| Process Optimization | Enables adjustments to casting methods and parameters |

| Risk Mitigation | Reduces likelihood of costly errors in production |

| Customer Collaboration | Promotes clear communication and alignment |

| Faster Time to Market | Speeds up the transition from concept to production |

Key Takeaways for Manufacturers and Clients

For both JC and its customers, prototyping is far more than a preliminary step—it is the foundation upon which precision, quality, and commercial success are built. Through prototyping, JC not only validates and optimizes the casting process but also fosters innovation, reduces costs, and strengthens customer relationships. As the industry advances, JC’s dedication to state-of-the-art prototyping ensures its leadership in delivering world-class investment castings and machined components.