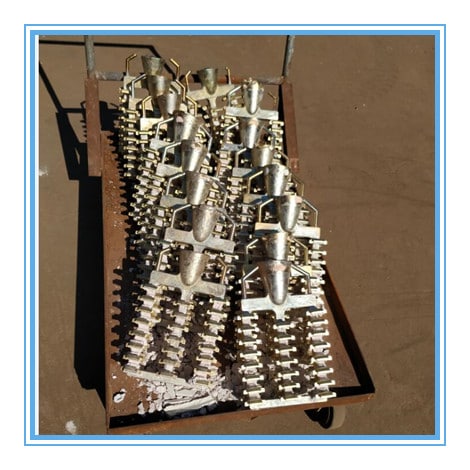

Brass investment casting is a process that creates parts through the metallic replication of wax models. Investment casting using molten brass results in a final product that is very smooth and detailed without flash or parting lines. This technique can create parts that are precise and lightweight.

JC Metal is a brass investment casting company and supplier. We can supply brass investment castings as per your design or specifications.

Brass Investment Casting

Almost any castable metal may be an investment cast. Brass investment casting is also by this process in our brass foundry.

The Brass Casting is be produced by lost wax investment casting process or die casting process.

The first step in investment casting is creating a master die out of wax. This wax pattern can be carved by hand or machine or maybe produced through brass casting molds. The die is a replica of the part that is to be produced. It is attached to a wax rod called a sprue. Several hundred wax patterns may be attached to the same sprue or it may be a single pattern. When the master dies are firmly attached, the assembly is inverted and dipped into a ceramic slurry called the investment. It may be dipped multiple times to achieve an even coating and the desired thickness. An alternative method is to mount the assembly in a flask and to pour in the investment. The investment is then left to dry, which requires many hours unless the process is aided by a fan or vacuum. After it has dried completely, the assembly is inverted and baked in an oven or furnace to melt or vaporize the wax. The mold is heated more than necessary to guarantee that there is no moisture or residual wax inside that would interfere with the liquid brass that is then poured into the space left by the wax. To thoroughly fill the mold, the molten metal can be drawn in through vacuum, positive air pressure, or centrifugal casting methods. Sometimes the force of gravity is enough. The brass cools and once it has hardened into a solid, the investment mold is removed to release the brass casting inside.

Materials for Brass Investment Casting we can make

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

Advantages of Brass Investment Casting

| Smaller diameter holes than forging, sand casting, and die casting |

| Tolerances within +/- .005 inches per linear inch |

| More environmental friendly |

| Highly complex dimensional geometry |

| No tooling cost |

| The typical surface finish of 175 RMS micro-inch |

| We can supply all kinds of machining products according to drawing, sample, or specific industry standards. |

| Many international advanced-level types of equipment such as CNC machining center, CMM, testing equipment, and so on. |

| OEM services and precise dimension, processing make sure the part is perfect in every way. |

Brass castings are used in many applications

Brass Investment Casting parts are used industrially, commercially, and domestically every day. Although Investment casting has been used for hundreds of years. But it is finding modern use in a wide variety of applications. Including dental and medical tools, engines, couplings, fittings, pipes, propellers, and thousands of other examples in the plumbing, aerospace, automotive, dental, medical, chemical, electrical, construction, mining, food processing, telecommunication, military, sports, precision parts, other industries.

Brass Investment Casting Supplier

We have Brass Casting Foundry and can offer Brass Copper Cast parts machined castings at very good prices! Besides, we have Copper Castings, Bronze castings for supplying, the weight can be up to 10 kilograms.

We undertake custom Brass casting Copper castings, Aluminium Bronze Castings, Aluminum Bronze casting, Beryllium Copper castings investment casting. Kindly contact us with your specs for a quote on requirements for Brass Castings and brass casting service