What is a Butterfly valve? It consists of a valve housing and a valve body. A flap having a rotatable disc shape or a double flat shape. Its function is to cut off the water flow. Its axis of rotation is perpendicular to the direction of water flow. When the valve body plane is in a state perpendicular to the water flow direction, the valve is closed. The butterfly valve has a rotatable disc or double flat valve. Suitable for large diameters and low heads. At present, the largest diameter has been used above 800cm, and the maximum head is 200 meters.

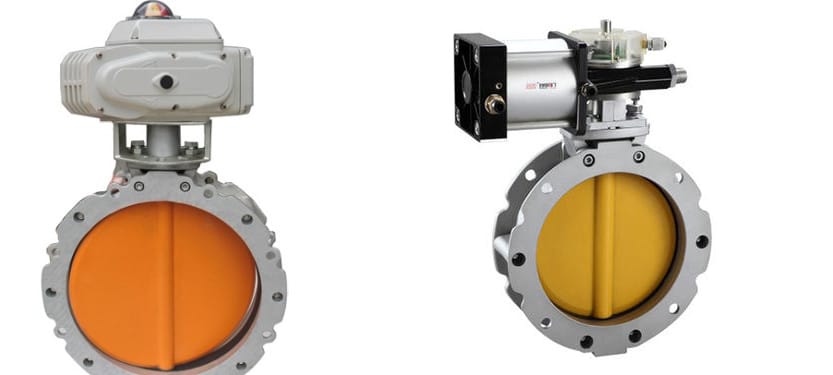

We are a Butterfly Valve manufacturer in China. We can OEM Butterfly Valve parts and Butterfly Valves casting as your request. Our superior butterfly valve is double eccentric in design. It can work the weight for up to 700 PSI. Our versatile butterfly valve has an adaptable elastic seat. This compose would work the weight for up to 232 PSI. Our pericentric butterfly valve is ordinarily designed with metal seating. It works the weight for up to 1450 PSI.

Applicable conditions Valves on the inlet pipe of large and medium-sized turbines.

Butterfly Valve Main components

1) Valve body. The function is a part of the water passage, through which the water flows, supports the weight of the valve, withstands the operating force and torque, and transmits the water pressure.

2) The door. The effect is to cut off the water flow when it is closed. Requires sufficient strength. When it is opened, the hydraulic loss is small in the center of the water flow, and it has good hydraulic characteristics.

3) Shaft and bearing: support the weight of the valve.

4) Locking ingots. The valve of the butterfly valve requires a lock ingot when it is fully closed or fully open.

5) Bypass valve and bypass pipe: reduce the torque when the main valve is opened, and eliminate the vibration under the moving water.

6) Air valve. When closing, the air is supplied to the butterfly valve. Prevent the steel pipe from being damaged by the vacuum. Exhaust when the forward valve is opened and filled with water. The valve has a hollow float suspended below the pilot piston and the hollow float is on the surface of the volute or tube. In addition, the vent is open to the atmosphere to vent or vent the volute and duct. When the pipe and the volute are filled with water, the pontoon floats to the limit position. The volute and the pipe are isolated from the atmosphere to prevent the water from overflowing.

7) Expansion joints. Easy to install and overhaul, the steel pipe has room for expansion and contraction when the temperature changes.

8) Sealing device. Prevent water leakage between the living body and the valve. The rubber band is mounted on the valve body or the valve. When the shutter is closed, compressed air is rushed into the shroud, and the shroud expands to seal the gap between the circumferences. Before the valve is opened, it should be vented and the belt retracted before the valve can be opened. The compressed air pressure in the shroud should be greater than the maximum head (excluding the water hammer boost value) (2-4)*10^5Pa. When not in air pressure or water pressure, the gap between the shroud and the shutter is 0.5-1mm.

Product Types

Concentric Disc, Double Off-Set Disc, Triple Off-Set Disc, Double(both) Flanged Ends, Wafer Type Ends, Lug Type Ends, Butt Welded Types Ends.

How Does It Work?

The butterfly valve, having a level round disk, is positioned in the center of the pipe, and the disk has a rod through it that is attached to a handle outwardly of the valve. This valve works by rotating the handle and turning the disk over either in a parallel position or opposite to the flow. Dislike the ball valve, the disk in the butterfly valve is dependably there inside the flow; along these lines, a sort of weight drop is constantly instigated in the flow, despite the situation of the valve.

Butterfly Valve manufacturer and foundry

At our Investment Casting Foundry, we can offer a custom silica sol investment casting service. For a variety of butterfly valve bodies and discs for a diverse range of applications. Most butterfly valve body and disc materials are from stainless steel. Stainless steel butterfly valve casting is also our advantages product. Our Casting tolerance of stainless steel butterfly valve body and disc can be controlled with ISO 8062 CT5-6 level. Each product can provide related testing reports.

Besides stainless steel casting, our foundry can also supply value-added services to our customers include Rough or precision machining, heat treatment, surface treatment, custom package, fast shipping, etc. If you have any inquiry on stainless steel investment casting for butterfly valve body & disc or other valve castings, kindly contact us freely.