Container Corner Casting, Container Castings

What is the Container corner casting? Shipping Container corner castings are the corners of a shipping container. Corner casting is the structural department of a shipping container. Its function is connecting to other containers both horizontally and vertically as well as being connected to transport modes including ship, rail, and road.

We are the manufacturers of Corner Casting. Our standard container Corner Castings are made from special steel designed for low temperature working at -40°C. These Corner Castings can be customized as per our customer’s specifications. Besides the carbon steel material corner casting, we have corner fittings available in the 304 316 stainless steel Container corner and aluminum Container corner.

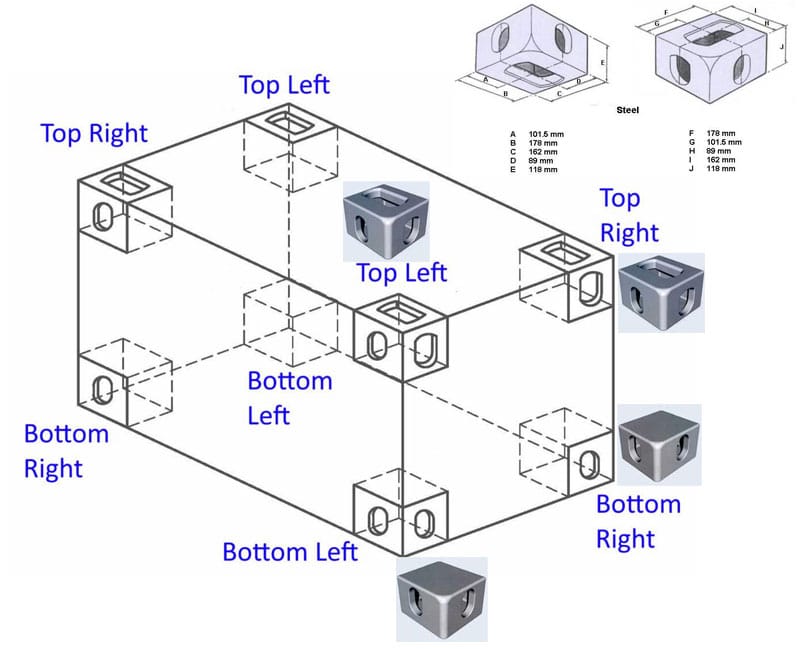

The types of Corner Casting.

A standard ISO container uses 8 corner castings consisting of Top Left, Top Right, Bottom Left, Bottom Right. 2 pcs of each part, Total is 8 pcs.

The top and bottom corner fittings are not exactly the same. The top corner fitting has an Acorn shape side hole whereas that of the bottom corner fitting is a semicircle.

Container Corner Castings ISO 1161 Details

- Material: High-Quality Casting Steel,or SCW490 material

- Size: 178mm x 162mm x 118mm, 7.01*2.44*4.65 inch

- Wall Thickness: 3/4 “

- Weight: 11KG per pcs, Each Set Comes With 8 pcs

- Standard Set: 8pcs/set,including 2TL,2TR,2BL,2BR

- Surface Treatment: Raw / Painting

- Certified and with dimensional requirements of ISO 1161, GL,BV,CCS,ABS,RINA,LR,NK,DNV etc.

- HS Code:7326909000

- Packing: 100 pcs are packed into one pallet, 250 sets into one 20ft container

- Applications: dry cargo container, refrigerated container, folding container, open top container, mobile home, steel structure

Cotnainer Corner Packing

Cast Steel Container Corner

Stainless Steel Casting Container Corner

Container Corner Casting

Our container corner castings are made by the Sand investment casting method.

Quality control

ISO container corner castings as the important part of the container, often withstand stacking, and the lifting, complex shape, General Casting forming, To ensure that performance requirements must be approved by the heat treatment up tp as follows result:

A normalizing (910°C) under the specimen yield strength, tensile strength, Elongation, progeny shrinkage, -40-degree temperature impact toughness, which must be completed in accordance with Classification Society requirement.

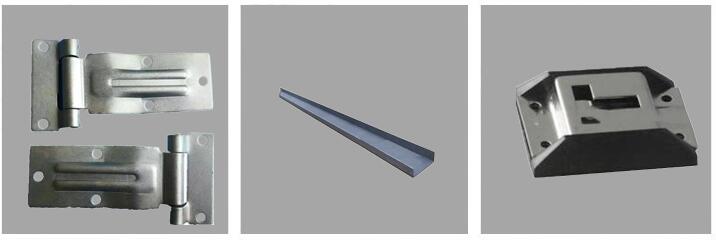

Related Products

Since the COVID 19 effects, the global container shortage is very severe. Most factories’ delivery extended. If you have any inquiries about container corners or container fittings, contact us today to get the latest news.