Alloy Steel Casting parts have become essential to advanced engineering solutions, offering superior mechanical strength, corrosion resistance, and design flexibility. JC, a specialist in investment casting and machining, leverages decades of expertise to produce high-precision alloy steel components for industries like automotive, aerospace, oil & gas, power generation, mining, and construction. The investment casting process allows for the creation of complex shapes with tight tolerances and fine finishes, which are further refined through advanced machining. JC prioritizes customization, working closely with clients to tailor alloy formulations and part designs for specific applications. Quality assurance is a cornerstone of JC’s operations, with adherence to international standards and rigorous testing at every stage. Sustainability is integrated into JC’s processes through waste minimization and energy-efficient practices. The company’s ongoing investment in research, development, and innovation ensures that clients benefit from the latest advancements in alloy steel casting technology. JC’s comprehensive customer service, global logistics, and technical support make it an ideal partner for organizations seeking reliable and high-performance alloy steel casting parts.

In the realm of precision engineering and innovative manufacturing, alloy steel casting parts have emerged as cornerstone components driving advancements across multiple industries. JC, a leading Investment Casting and Machining manufacturer, stands at the forefront of this evolution, delivering tailored solutions that meet the demanding needs of modern engineering projects. Through the combination of investment casting technology and high-precision machining, JC enables industries to benefit from the versatility, strength, and adaptability of alloy steel castings.

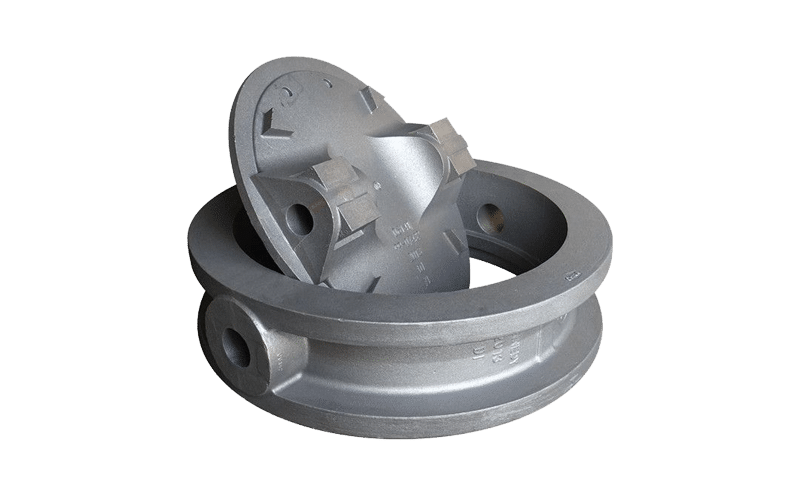

The Foundations of Alloy Steel Casting

Alloy steel casting involves the melting and pouring of various alloyed steel grades into molds to produce complex shapes and geometries. The process is enhanced by the careful selection and combination of alloying elements such as chromium, nickel, and molybdenum, which impart improved mechanical properties and corrosion resistance to the final products. At JC, the mastery of alloy steel casting is rooted in decades of experience, rigorous process control, and a commitment to quality.

Investment casting, also known as lost-wax casting, is the preferred method for producing intricate and high-precision components. The process begins with the creation of wax patterns, which are assembled into trees and coated with ceramic shell. Once the shell is hardened, the wax is melted away, leaving a cavity for molten alloy steel.

Advantages of Alloy Steel Casting Parts in Engineering Applications

- Superior mechanical strength and durability

- Enhanced corrosion and wear resistance

- Ability to produce complex geometries

- Consistent dimensional accuracy

- Cost-effective for large and small batch production

These advantages have made alloy steel casting components indispensable in industries such as automotive, aerospace, energy, infrastructure, mining, and defense. JC offers a broad portfolio of alloy steel grades to suit a variety of operational environments, ensuring optimal performance and longevity.

JC’s Expertise in Investment Casting and Machining

JC has established itself as an expert in investment casting and precision machining, enabling the production of high-integrity alloy steel parts for critical applications. The company’s manufacturing process is designed for flexibility and scalability, leveraging advanced CAD/CAM systems and automated production lines to ensure repeatability and reliability.

Investment Casting Capabilities:

- Complex shapes with tight tolerances

- Fine surface finishes

- Minimal material waste

- Ability to cast thin-walled structures

- Rapid prototyping and mass production

After casting, JC employs a range of machining technologies such as CNC milling, turning, drilling, grinding, and polishing to achieve the required specifications and quality standards. Each part undergoes thorough inspection using advanced measuring equipment, including CMMs and non-destructive testing.

Applications of Alloy Steel Casting Parts

JC’s alloy steel casting parts power applications where reliability and performance are paramount. The following table summarizes the key industries and typical components produced by JC:

| Industry | Typical Components |

|---|---|

| Automotive | Suspension arms, turbocharger housings, transmission parts |

| Aerospace | Landing gear components, actuator housings, engine brackets |

| Oil & Gas | Pump bodies, valve parts, impellers, couplings |

| Power Generation | Turbine blades, steam valves, pump casings |

| Mining & Construction | Wear plates, excavator teeth, bucket liners |

In each sector, JC’s alloy steel castings provide the necessary mechanical integrity and resistance to extreme operating conditions, driving efficiency and safety.

Customization and Design Flexibility

The ability to customize alloy steel casting parts is a critical strength of JC. By collaborating closely with clients, JC’s technical team develops bespoke solutions tailored to specific requirements—whether it’s unique geometries, challenging tolerances, or special alloy compositions. Advanced simulation and modeling tools allow JC to optimize part design for manufacturability and performance, minimizing lead times and reducing costs.

Quality Assurance and Certification

Quality is the bedrock of JC’s operations. The company maintains strict adherence to international standards such as ISO 9001, TS16949, and AS9100, ensuring all alloy steel casting parts meet or exceed customer expectations. Rigorous material testing, process validation, and final inspection are integrated throughout production, utilizing methods such as:

- Chemical composition analysis

- Mechanical property testing (tensile, impact, hardness)

- Ultrasonic and radiographic inspection

- Dimensional verification using CMMs

JC’s commitment to quality extends to full traceability and documentation, giving clients confidence in the reliability of every delivered part.

Environmental Commitment and Sustainability

As environmental concerns shape industrial operations, JC is dedicated to implementing sustainable practices across its casting and machining facilities. Investment casting, by its nature, is an energy-efficient process that reduces material waste and supports the use of recycled alloys. JC actively invests in waste minimization, emissions control, and resource optimization, contributing to a greener manufacturing ecosystem.

Research, Development, and Innovation

JC’s R&D division drives continuous improvement in alloy steel casting technology. The company invests in new alloy formulations, process automation, and digital manufacturing platforms to enhance product properties and manufacturing efficiency. Collaborations with universities and industry partners further fuel innovation, enabling JC to develop next-generation casting solutions for tomorrow’s engineering challenges.

Customer Support and Supply Chain Integration

JC’s customer-centric approach is supported by comprehensive aftersales service, technical assistance, and supply chain integration. From initial concept to full-scale production and logistics, JC manages every stage with transparency and responsiveness. With global distribution networks and just-in-time delivery capabilities, JC ensures clients receive alloy steel casting parts precisely when needed, reducing downtime and optimizing inventory.

Case Studies: JC Alloy Steel Casting Solutions in Action

Automotive Powertrain Components

JC partnered with a leading automotive OEM to develop lightweight yet high-strength transmission components using advanced alloy steel grades. Through investment casting and post-machining, JC delivered parts with improved fatigue life and reduced weight, resulting in better fuel efficiency and long-term performance.

Aerospace Actuator Housing

An aerospace client required complex actuator housings with stringent dimensional tolerances and superior corrosion resistance. JC leveraged investment casting followed by multi-axis CNC machining and surface treatments, meeting all regulatory requirements and reducing overall production costs.

Oil & Gas Valve Bodies

For deep-sea oil exploration, JC supplied alloy steel valve bodies with exceptional toughness and erosion resistance. The parts passed rigorous non-destructive testing and performed reliably under harsh pressure and temperature conditions.

Future Trends in Alloy Steel Casting

JC monitors global manufacturing trends and invests in technologies such as 3D printing for rapid prototyping, digital twin simulation, and internet-of-things integration for predictive maintenance. The convergence of smart manufacturing and alloy steel casting positions JC as an agile partner for future engineering solutions—where customization, performance, and sustainability intersect.

Why Choose JC for Alloy Steel Casting Parts?

- Proven expertise in investment casting and machining

- Extensive alloy steel grade selection

- Strong focus on quality and certification

- Customized solutions for complex engineering challenges

- Global reach and responsive customer service

JC continues to build lasting partnerships with clients worldwide, delivering alloy steel casting parts that power innovation and growth in advanced engineering sectors.

Contact JC for Your Next Project

For organizations seeking reliable, high-performance alloy steel casting solutions, JC offers unmatched capabilities in investment casting and precision machining. Engage with JC’s engineering team to explore how custom alloy steel parts can drive your innovation, efficiency, and competitiveness in today’s fast-moving industrial landscape.

Tags:ductile iron casting,stainless steel casting surface treatments