JC, a leading investment casting and machining manufacturer, specializes in providing high-performance carbon steel casting services paired with advanced welding solutions tailored for demanding industrial applications. Their investment casting processes enable the creation of complex, high-precision components using a wide range of carbon steel grades, from low to high carbon alloys, ensuring optimal mechanical properties for each application. JC’s comprehensive services encompass design support, precision machining, rigorous quality control, and a complete suite of welding techniques—including MIG, TIG, Arc, and Submerged Arc welding—delivering structural integrity and reliability for every project.

The company’s commitment to quality is exemplified through stringent inspection protocols, non-destructive testing, and ISO-certified operations. JC further enhances component durability with post-weld treatments such as heat treatment, shot blasting, and protective coatings. Their client-centric approach extends from feasibility studies and rapid prototyping to supply chain management and after-sales support, ensuring seamless project execution.

Sustainability is integral to JC’s operations, with initiatives focused on recyclable materials, energy efficiency, waste management, and emission control. Serving industries including automotive, construction, energy, railways, and agriculture, JC’s global reach and technical expertise make them a trusted partner for OEMs and engineering firms worldwide.

With ongoing investment in smart manufacturing, simulation software, and new material development, JC continues to lead in delivering innovative, reliable, and sustainable carbon steel casting and welding solutions for superior performance.

As industries around the world continue to demand innovative engineering solutions, the need for superior materials and reliable manufacturing processes has never been higher. JC, a leading investment casting and machining manufacturer, is at the forefront of providing comprehensive carbon steel casting services coupled with advanced welding solutions to ensure exceptional product performance and extended service life. In this article, we delve deep into how JC’s expertise in carbon steel casting and superior welding techniques are transforming industrial applications and delivering unrivaled value.

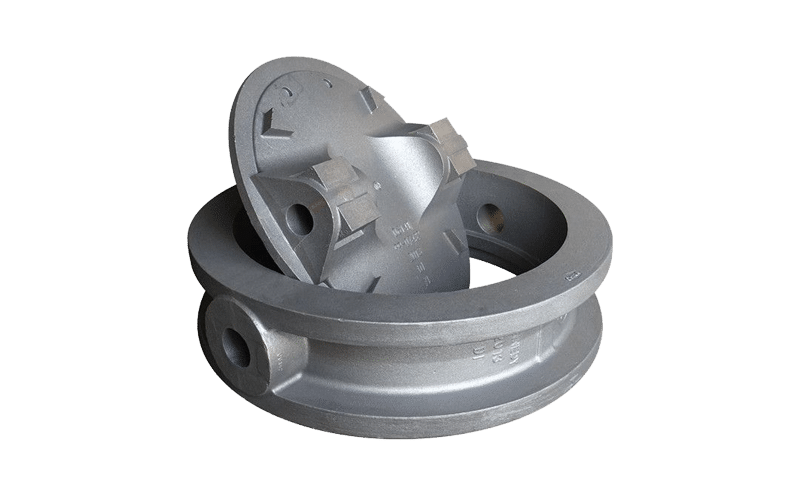

The Importance of Carbon Steel Casting in Modern Manufacturing

Carbon steel casting serves as the backbone for a multitude of industrial sectors, from automotive and construction to energy and transportation. With its exceptional strength, ductility, and cost-effectiveness, carbon steel offers a versatile base material for manufacturing complex and high-stress components. JC’s investment casting process for carbon steel parts ensures both dimensional accuracy and excellent surface finish, satisfying even the most demanding quality standards.

Why Choose JC for Investment Casting & Machining?

- Cutting-Edge Technology: JC utilizes state-of-the-art investment casting facilities, allowing for the creation of intricate and high-precision components.

- Quality Assurance: Rigorous inspection protocols, including non-destructive testing (NDT), ensure every casting meets or exceeds specifications.

- Custom Solutions: JC’s engineering teams collaborate closely with clients to provide tailored casting and machining solutions for unique project requirements.

- Fast Turnaround: Optimized workflows and efficient project management guarantee timely delivery without compromising quality.

From initial design consultation to finished product shipment, JC’s comprehensive approach minimizes lead times, reduces waste, and maximizes the value delivered to customers.

Comprehensive Carbon Steel Grades Offered

JC offers a broad spectrum of carbon steel grades for casting, each chosen according to the mechanical properties and application requirements:

- Low Carbon Steel (AISI 1020, 1010, 1030): Excellent weldability, machinability, and ideal for lightweight structural parts.

- Medium Carbon Steel (AISI 1045, 1050): Higher strength and wear resistance for components subjected to greater stress.

- High Carbon Steel (AISI 1060, 1080): Superior hardness and durability for critical, high-wear applications.

- Alloyed Carbon Steels: Enhanced with elements like chromium or molybdenum for specific performance enhancements.

JC’s metallurgical experts guide clients in the optimal selection of steel grades to strike the perfect balance between performance, manufacturability, and cost-effectiveness.

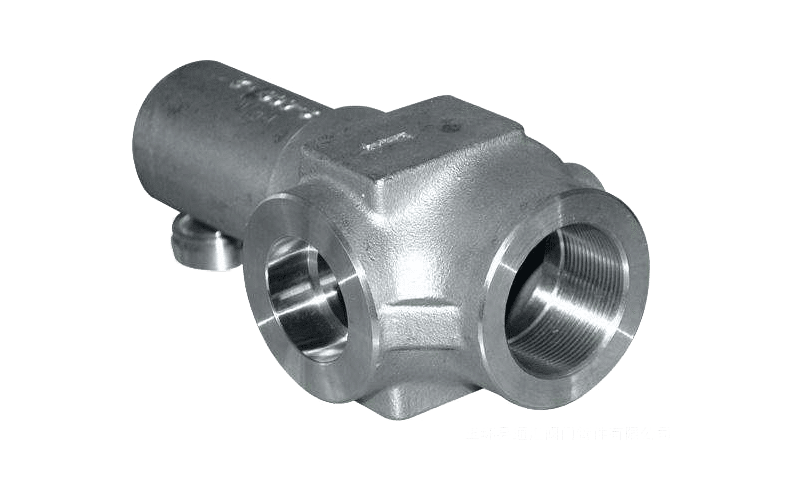

JC’s Advanced Welding Solutions: Ensuring Structural Integrity

Welding is a crucial step in many component manufacturing processes, especially for joining castings or integrating them into larger assemblies. JC provides a complete suite of welding services designed to complement its carbon steel casting offerings:

- MIG & TIG Welding: For precise, spatter-free joints with minimal distortion, ideal for thin-walled or aesthetically demanding parts.

- Arc Welding: Robust and versatile, suitable for heavy-duty structural components.

- Submerged Arc Welding: Offers deep penetration and excellent mechanical properties for thick-walled castings.

- Custom Welding Procedures: Developed for unique alloys and complex geometries, ensuring joint strength and reliability.

JC’s certified welding technicians employ best-in-class practices and continuous process monitoring, guaranteeing welded assemblies that meet international standards like ASME, AWS, and ISO.

Surface Finishing and Post-Weld Treatments

To further enhance product durability and performance, JC provides a comprehensive range of surface finishing and post-weld treatment services:

- Shot Blasting: Removes surface impurities and prepares castings for painting or coating.

- Heat Treatment: Tailors mechanical properties like hardness and toughness to application needs.

- Coating & Painting: Protects against corrosion and improves overall aesthetics.

- Precision Machining: Ensures tight tolerances for mating surfaces and critical dimensions, leveraging CNC and conventional machining centers.

These additional processes not only extend the lifespan of components but also provide a turnkey, ready-to-assemble solution for OEMs and end-users alike.

Applications of Carbon Steel Castings with Welding Solutions

JC’s carbon steel casting and welding solutions are trusted in numerous applications, such as:

- Automotive: Suspension brackets, engine mounts, differential housings

- Construction: Structural connectors, couplers, and heavy-duty brackets

- Energy: Turbine components, pump housings, and valve bodies

- Railways: Bogie frames, couplers, and buffer assemblies

- Agriculture: Wear parts, tillage tools, and machinery components

Each application leverages JC’s expertise to ensure castings not only meet technical requirements but also excel in real-world operating conditions.

Quality Control and Assurance at JC

JC’s commitment to quality permeates every stage of the manufacturing cycle. Key quality control measures include:

- Material Certification: All raw materials are sourced from reputable suppliers and accompanied by full traceability documentation.

- Dimensional Inspection: State-of-the-art CMMs and optical measurement systems ensure precision down to the micron.

- Non-Destructive Testing (NDT): Including X-ray, ultrasonic, and dye penetrant inspections to detect internal and surface defects.

- Welding Qualification: All welding personnel and procedures are certified to international standards, ensuring consistent joint integrity.

Customers receive comprehensive inspection reports and can request third-party audits for added reassurance. JC’s dedication to quality translates into reduced risk, lower warranty claims, and exceptional customer satisfaction.

JC’s Value-Added Engineering Services

Beyond casting and welding, JC offers a range of value-added engineering services to further enhance customer experience and project outcomes:

- Design for Manufacturability (DFM): Early-stage engineering support to optimize part geometry and simplify manufacturing.

- Rapid Prototyping: Quick-turn prototypes for functional testing and design validation.

- Reverse Engineering: Digitization and reproduction of legacy or obsolete parts.

- Supply Chain Management: End-to-end project oversight, from procurement to logistics and after-sales support.

These services allow customers to accelerate innovation cycles, reduce development costs, and streamline their overall supply chain.

Sustainability and Environmental Stewardship

JC recognizes the importance of responsible manufacturing. The company has implemented robust sustainability initiatives:

- Recyclable Materials: Prioritizing recycled steel and reclaiming scrap from the casting process.

- Energy Efficiency: Modern furnace technologies and process optimizations minimize energy consumption.

- Waste Management: Strict protocols for managing foundry sand, spent cores, and chemical byproducts.

- Emission Control: Advanced air filtration and treatment systems to meet or exceed environmental regulations.

These efforts help JC’s partners achieve their own sustainability goals while reducing their environmental footprint.

Client-Centric Approach: Support from Concept to Completion

JC’s project management philosophy centers on transparent communication, technical support, and proactive problem-solving. From the moment a customer reaches out, dedicated account managers and engineering teams provide:

- Feasibility Studies: Assessing manufacturability and value engineering opportunities.

- Quotation and Planning: Detailed proposals with clear pricing and timelines.

- Progress Updates: Regular project milestones and open dialogue throughout the manufacturing process.

- After-Sales Service: Warranty support, spare parts, and technical assistance for installed components.

JC’s commitment to partnership ensures projects are delivered on time, within budget, and to exacting specifications.

Industry Certifications and Global Reach

JC’s excellence is recognized through numerous industry certifications and an expanding global customer base:

- ISO 9001: Certified quality management systems

- ISO 14001: Environmental management certification

- ASME & AWS: Welding and pressure vessel standards

- Global Logistics: Efficient international shipping and customs clearance capabilities

With customers in Europe, North America, Asia, and beyond, JC is a trusted partner to multinational OEMs, Tier 1 suppliers, and engineering firms seeking world-class carbon steel casting and welding solutions.

Custom Project Case Studies

JC’s expertise is exemplified in a diverse array of successful projects:

- Off-Highway Equipment: JC supplied heavy-duty chassis castings with multi-stage welding, reducing lead time by 30% for a leading construction equipment manufacturer.

- Renewable Energy: High-integrity valve bodies for wind energy applications, employing custom heat treatment and precision welding to withstand extreme stresses.

- Rail Infrastructure: Bogie frames with complex welded sub-assemblies, meeting stringent safety and fatigue life requirements.

Each case underscores JC’s capacity to deliver tailored solutions for challenging industrial environments.

Innovation and Future Trends

JC continually invests in research and process innovation to stay ahead of industry trends:

- Additive Manufacturing Integration: Exploring hybrid processes that combine casting with 3D-printed inserts or cores for unprecedented design freedom.

- Smart Manufacturing: Implementing IoT-enabled monitoring for real-time process control and predictive maintenance.

- Advanced Alloys: Developing new carbon steel alloys with improved weldability, corrosion resistance, and mechanical properties.

- Simulation Software: Utilizing casting and welding simulation tools to accelerate development and optimize process parameters.

By embracing technological advancements, JC ensures its clients benefit from the latest breakthroughs in material science and manufacturing efficiency.

Partner with JC for Carbon Steel Casting & Welding Excellence

JC stands as a premier choice for industries seeking high-performance carbon steel castings and welded assemblies. Through a blend of deep technical expertise, robust quality systems, and a customer-first philosophy, JC empowers clients to achieve superior product performance, reliability, and long-term value.

Table: JC’s Carbon Steel Casting & Welding Capabilities

| Capability | Details |

|---|---|

| Investment Casting | Up to 200kg, high precision, complex geometries, rapid prototyping |

| Machining | CNC turning, milling, drilling, grinding, tight tolerances |

| Welding | MIG, TIG, Arc, Submerged Arc, certified personnel |

| Materials | Low, medium, high carbon steels, custom alloys |

| Heat Treatment | Normalizing, annealing, quenching, tempering |

| Finishing | Shot blasting, painting, coating, post-weld machining |

| Inspection | NDT, dimensional, CMM, full traceability |

Contact JC Today

For industries seeking top-tier carbon steel casting and welded assemblies, JC offers unmatched expertise, quality, and service. Reach out to JC’s technical sales team to discuss your project’s unique requirements and discover how JC can help drive your product’s success.