Bronze casting has evolved significantly at JC Investment Casting & Machining Manufacturer, driven by the use of advanced alloying techniques. By introducing elements like tin, aluminum, silicon, manganese, and lead, JC enhances the mechanical properties, machinability, and mold filling capabilities of bronze. This results in superior castings with consistent quality, lower waste, and faster turnaround times. JC’s investment casting process incorporates precise alloy melting, advanced mold design, and rigorous quality control, ensuring that each batch meets industry standards and specific client needs. The strategic selection of alloys enables JC to deliver bespoke solutions for a wide range of applications, from marine propellers and industrial valves to artistic sculptures. Through continuous research, innovation, and collaboration, JC maintains a leading position in alloyed bronze casting, expanding into new global markets and setting benchmarks for efficiency and sustainability. The commitment to training and customer support further drives JC’s reputation for excellence in investment casting and machining services.

The Evolution of Bronze Casting at JC

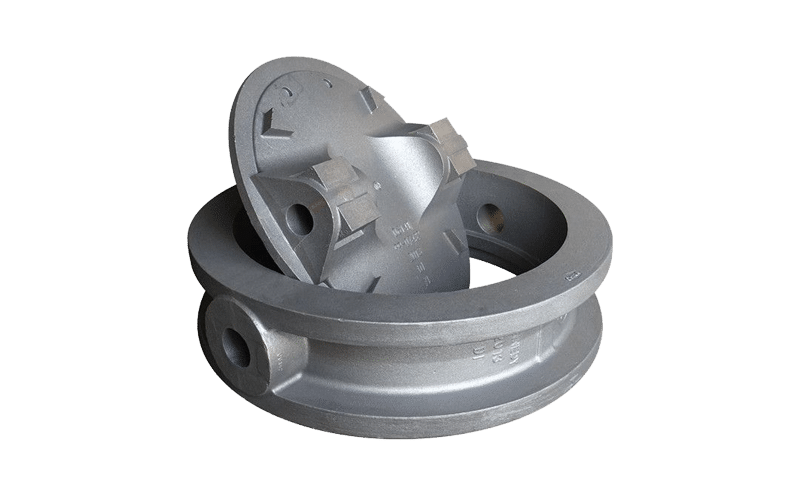

Bronze casting has been a pivotal process in manufacturing, finding its origins thousands of years ago. Today, JC Investment Casting & Machining Manufacturer stands at the forefront of innovation, leveraging new alloy compositions to enhance efficiency and pour quality. The integration of specific alloying elements into bronze has dramatically improved the casting process, yielding better mechanical properties, smoother finishes, and higher overall output. This article explores how JC has redefined the bronze casting service by utilizing advanced alloy combinations and optimized production techniques.

The Role of Alloying in Bronze Casting

Why Alloys Matter

Alloying is the process of combining metals to obtain desired properties that pure metals cannot provide. In bronze casting, copper is the primary element, but the addition of tin and other metals like aluminum, silicon, or manganese creates alloys with enhanced performance. JC’s expertise in selecting and manipulating alloy compositions allows the company to tailor bronze properties to meet stringent customer requirements.

Common Alloying Elements in JC’s Bronze Casting

- Tin: Increases hardness and corrosion resistance.

- Aluminum: Improves strength-to-weight ratio and enhances machinability.

- Silicon: Adds fluidity for better molding and casting capability.

- Manganese: Boosts wear resistance and impact strength.

- Lead: Used in controlled amounts for improved lubrication, especially in bearing applications.

Efficiency Gains from Alloyed Bronze Casting

Superior Mechanical Properties

JC’s alloyed bronze provides exceptional mechanical properties, leading to reduced failure rates and longer component lifespan. By selecting the optimal blend for each application, JC ensures castings offer improved tensile strength, toughness, and fatigue resistance. This translates to fewer re-castings and repairs, boosting the overall efficiency of the manufacturing process.

Enhanced Machinability and Post-Casting Operations

The addition of specific alloys can decrease the time required for machining and finishing. For example, silicon bronze is well-known for its ease of machining, and JC’s investment casting process leverages this trait for fast turnaround times. This results in lower operational costs, less tool wear, and higher throughput, ultimately benefiting customers with shorter delivery schedules.

Improved Casting Yield and Material Utilization

Alloyed bronze tends to flow better into complex molds, minimizing defects such as porosity and cold shuts. JC’s R&D team continually tests new alloy formulations to maximize mold filling and minimize waste. The result is an increase in casting yield: more usable parts per batch, and less scrap metal generated. This efficient material utilization supports JC’s commitment to sustainability and cost-effectiveness.

JC’s Investment Casting Process: Alloy Integration

Precise Alloy Melting

JC employs state-of-the-art induction furnaces capable of maintaining accurate temperature controls. The melting process incorporates alloy elements in precise ratios, ensuring homogeneous distribution throughout the bronze. This uniformity is critical for consistent part quality and repeatable results, which are hallmarks of JC’s bronze casting services.

Wax Pattern and Mold Preparation

JC’s casting process starts with advanced CAD modeling and wax pattern production, enabling complex geometries and intricate surface details. Alloyed bronze’s improved flow and mold filling properties allow these intricate patterns to be faithfully reproduced in the final castings. JC’s engineers optimize mold design to take full advantage of the enhanced properties of alloyed bronze, ensuring high integrity and minimal post-cast work.

Quality Control and Testing

Each batch at JC undergoes rigorous quality testing, including spectrographic analysis to confirm alloy concentrations and mechanical evaluation for strength, ductility, and surface finish. By utilizing alloying technology, JC consistently delivers bronze castings of superior and repeatable quality. Non-destructive testing methods, such as ultrasonic or X-ray inspections, further validate the integrity of cast parts.

Machining Advantages with Alloyed Bronze

Tool Life Extension

Machining bronze alloys can be abrasive, but JC’s selection of alloying elements leads to a balance between hardness and machinability. This balance means that tools last longer during CNC machining operations, reducing replacement costs and downtime. With advanced toolpath strategies and continuous monitoring, JC maximizes machining performance even on high-volume jobs.

Surface Finish Quality

Bronze alloys from JC produce superior surface finishes after machining, which is vital for components requiring tight tolerances and minimal friction. The combination of alloy properties and precision machining ensures that cast and machined parts meet or exceed client specifications across a range of industries, from aerospace to marine.

Alloy Selection Strategies at JC

Application-Oriented Alloy Development

JC’s engineering team works closely with clients to determine the optimal alloy for each application. Factors considered include operating environment, mechanical load, corrosion potential, and post-processing requirements. Whether for ship propellers, pump components, or ornamental art, JC customizes alloy selection to fit the performance and budgetary needs of its customers.

Continuous Research and Improvement

JC invests heavily in research and development to keep up with evolving industry standards. Collaborations with metallurgical institutes and ongoing trials of new alloy combinations ensure the company remains ahead of competitors. The data collected from pilot projects feeds directly back into design optimizations and process improvements, creating a cycle of perpetual advancement.

Case Studies: Real-World Efficiency from Alloyed Bronze Casting

Marine Propeller Efficiency

A recent project involved casting large marine propellers using aluminum bronze. JC’s alloy expertise allowed for lighter, stronger propellers with superior resistance to saltwater corrosion. The result: extended service intervals and improved vessel performance.

Industrial Valve Components

For industrial valve manufacturers, JC provided silicon bronze castings with exceptional dimensional accuracy and reduced porosity. This led to valves with higher pressure ratings and longevity, minimizing maintenance costs for end-users.

Artistic Sculptures and Custom Orders

JC’s alloyed bronze enabled artists to realize intricate sculptures without the surface defects often associated with traditional bronze. The improved flow and reduced shrinkage delivered consistent results, empowering creative expression and customer satisfaction.

Future Trends: Alloy Innovation in Bronze Casting

Integration of Smart Alloys

JC is exploring the use of smart alloys that can self-heal minor cracks or change properties under external stimuli. These innovations promise to further enhance casting efficiency, reduce lifecycle costs, and introduce new functionalities for demanding applications.

Sustainability and Recyclability

Today’s manufacturing landscape demands sustainable solutions. JC focuses on developing bronze alloys that incorporate recycled materials without sacrificing performance. This not only lowers environmental impact but also aligns with global initiatives for responsible production.

Quality Assurance at JC

Certifications and Standards Compliance

JC’s commitment to quality is evident in its adherence to international standards such as ISO 9001 and ASTM specifications. Alloyed bronze castings undergo comprehensive testing and documentation, assuring customers of consistent excellence and reliability.

Customer-Centric Approach

The company’s customer support team works diligently to address specific casting challenges, recommend optimal alloy solutions, and provide after-sales service. This tailored approach, combined with alloy-driven efficiency, solidifies JC’s reputation as a trusted partner in investment casting and machining.

Advanced Technologies Supporting Alloyed Bronze Casting

Simulation and Modeling

JC leverages simulation software to predict alloy behavior during casting and cooling. These digital models help refine alloy compositions for maximum efficiency, reducing trial-and-error cycles and speeding up product development.

Automated Process Control

With automated monitoring and control systems, JC ensures that alloy mixing and casting parameters remain within tight tolerances. This minimizes human error and guarantees repeatable results, critical for large-scale production runs.

Collaborative Partnerships for Alloy Development

Supplier Relationships

JC works closely with raw material suppliers to source high-purity metals and alloying elements. These relationships allow for rapid integration of new materials, keeping JC at the cutting edge of alloy technology.

Industry Feedback Loops

Feedback from clients and industry partners informs JC’s ongoing alloy development efforts. This collaborative ecosystem ensures that JC’s alloyed bronze castings continue to meet the evolving needs of global markets.

Bronze Alloy Customization: Delivering Unique Solutions

Bespoke Alloy Formulations

JC’s metallurgical knowledge enables the creation of bespoke bronze alloys tailored for niche applications. Whether the requirement is enhanced magnetic properties, specific color hues, or ultra-high wear resistance, JC can deliver unique solutions that give clients a competitive edge.

Rapid Prototyping and Testing

Using investment casting and flexible alloy development, JC offers rapid prototyping services to validate material choices before full-scale production. This agile approach reduces risk and shortens time-to-market for new products.

Training and Workforce Development

Skilled Technicians

JC invests in continuous training for its workforce, ensuring technicians are proficient in the latest alloy casting and machining techniques. This investment pays dividends in efficiency, safety, and quality output.

Knowledge Sharing

JC actively publishes research findings, best practices, and case studies to foster industry-wide understanding of alloy benefits in bronze casting. This leadership role helps raise overall standards and promotes innovation in the field.

Challenges and Solutions in Alloyed Bronze Casting

Managing Alloy Complexity

While alloys offer many advantages, their complexity can introduce challenges in melting, mixing, and solidification. JC addresses these issues through advanced process controls, rigorous testing, and continuous improvement initiatives.

Maintaining Cost Efficiency

Certain alloying elements can be expensive. JC balances performance gains against material costs to ensure that clients receive the best value. Bulk purchasing agreements and recycling initiatives further optimize cost efficiency.

Global Impact and Market Expansion

Expansion into New Industries

With the efficiency gains provided by alloyed bronze casting, JC is able to penetrate new markets such as renewable energy, medical devices, and high-performance automotive components. Each sector benefits from the tailored properties and reliability of JC’s castings.

International Collaborations

JC partners with overseas companies to share alloy innovations and casting expertise. These collaborations facilitate technology transfer, open up new opportunities, and reinforce JC’s leadership position in investment casting and machining.

Summary Table: Alloy Benefits in JC’s Bronze Casting Service

| Alloying Element | Key Benefits | Typical Applications |

|---|---|---|

| Tin | Enhances hardness, corrosion resistance | Bearings, gears |

| Aluminum | Improves strength, machinability | Marine components |

| Silicon | Boosts casting fluidity | Valve parts, artistic works |

| Manganese | Increases wear resistance | Industrial machinery |

| Lead | Improves lubrication | Heavy-duty bearings |