Ductile iron has rapidly developed as cast iron material after gray cast iron. JC ductile iron foundry is one of the most modern Ductile Iron Foundries in China. We can manufacture and provide high-quality ductile iron castings at competitive prices throughout China market and around the world. Now, let’s start with the Ductile Iron casting raw materials—Ductile Iron!

What is Ductile Iron?

Ductile Iron is also called ductile cast iron, spheroidal graphite cast iron, or nodular cast iron. It is a kind of high-strength, graphite-rich cast iron material for iron castings.

Ductile iron has the content of the spherical (round) graphite structures in the metal. So its impact and fatigue resistance, elongation, and wear resistance durability and elasticity are good. Its mechanical properties far exceed those of standard cast irons.

Ductile iron is an alloy of carbon and iron. Its comprehensive performance is like steel. For the same section size. its weight is about 10 percent less than steel.

What is Ductile Iron made?

Ductile iron is not from iron or steel scrap. It is made primarily from the crude iron that is produced by smelting ore in a blast furnace.

Commonly it is called ‘pig iron.’ Pig iron content is about 90% iron with high carbon. Its chemical properties are very stable. Using a blast furnace, the pig iron is melted down and has carbon forced into the material beyond its normal capacity.

When the metal cools in its cast, Silicon, sulfur, and manganese help the excess carbon form the spherical graphite nodules. This process creates a durable, wear-resistant metal-Ductile Iron.

After chemical analysis of ductile iron, there are a few main elements were found:

What are the Compositions of Ductile Iron?

| Compositions | Contents |

| Iron | 94% |

| Carbon | 3.2 – 3.60% |

| Silicon | 2.2 – 2.8% |

| Manganese | 0.1 – 0.2% |

| Magnesium | 0.03 – 0.04% |

| Phosphorus | 0.005 – 0.04% |

| Sulfur | 0.005 – 0.02% |

| Copper | <= 0.40% |

Note:

- To improve the strength of ductile iron, additional tin or copper can be added.

- To improve corrosion resistance, copper, nickel, or chromium can replace anywhere from 15-30% of the iron.

The benefits and advantages of Ductile Iron

One of the major advantages of this production process is how easy ductile iron is to cast, and how cheap it is compared to other similar metals, such as steel.

Ductile iron is very strong compared to regular cast iron (gray iron). The tensile strength of cast iron is 20,000 – 60,000 psi. But the ductile iron starts at 60,000 psi and can reach 120,000 psi. The yield strength of ductile iron is generally 40,000 – 90,000 psi. But the cast iron yield strength is too low to measurable.

Ductile iron has a graphite content. So it has excellent wear resistance. When something rubs against ductile iron, the ductile iron wears away much slower than many other metals. The wear resistance is partly from the graphite structures. Its function is like a dry lubricant on the iron.

Although ductile iron is harder to work with than regular gray cast iron, Ductile iron dissipates heat very well. It can be machined fairly easily.

Advantages of Ductile Iron There are several advantages that ductile iron provides designers:

- 1.Easy to cast and machined.

- 2.Excellent strength to weight ratio.Hardness than regular cast iron (gray iron)

- 3.Much lower cost than steel.

- 4.Good ability to dissipates (gets rid of) heat very well

- 5.Ductile iron provides a designer with an exceptional combination of toughness, low-cost manufacturing, and reliability.

Properties of Ductile Iron

To create different grades of ductile iron, it must control the matrix structure around the graphite during the casting process or through subsequent heat treatment.

In order to create the desired matrix (microstructures), The minor compositional differences between the different grades of ductile iron exist

Ductile iron can be considered as steel with graphite spheroids dispersed throughout its matrix. The qualities of the metallic matrix in which the graphite spheroids are suspended have a significant effect on ductile iron’s properties. But the graphite spheroids themselves do not.

There are several matrices found in ductile iron. The unique microstructure of each metal changes its physical properties.

The most common being as below:

- 1.Ferrite: a pure, ductile, flexible iron with little strength. This matrix has poor wear resistance. But high impact resistance and good machinability.

- 2.Pearlite: a mechanical mixture of ferrite and iron carbide (Fe3C). It is relatively hard, with moderate ductility. It has high strength, good wear resistance, moderate impact resistance, and good machinability.

- 3.Pearlite/Ferrite: a structure consisting of a mixture of pearlite and ferrite, and the most common matrix for commercial grades of ductile iron.

Standard specification for ductile iron castings.

ASTM A536 refers to the standard specifications for ductile iron castings. As per Ductile iron grade, it offers different properties.

A536 Grade 60-40-18 has maximum ductility, excellent machinability, and low-temperature toughness.

A536 Grade 120-90-02 has very high strength and wear resistance (though not as wear-resistant as our chrome white irons).

If you need moderate ductility and impact resistance, coupled with high strength, ASTM A536 Grade 80–55–06 is a good choice.

Our ductile iron castings meet the ASTM A536 standard. This ensures that our customers obtain the engineered properties required for their specific application. All of our castings are manufactured with the latest heat treatment/chemistry design and controls.

We offer several grades of ductile iron casting, including:

- ASTM A536 Grade 60-40-18

- ASTM A536 Grade 65-45-12

- ASTM A536 Grade 80-55-06

- ASTM A536 Grade 100-70-03

- ASTM A536 Grade 120-90-02

- Solid Solution Ductile Iron

- Low-Temperature Impact Resistant ASTM A536

- We also pour austenitic ductile iron.

What is Ductile Iron Used For? (main Applications)

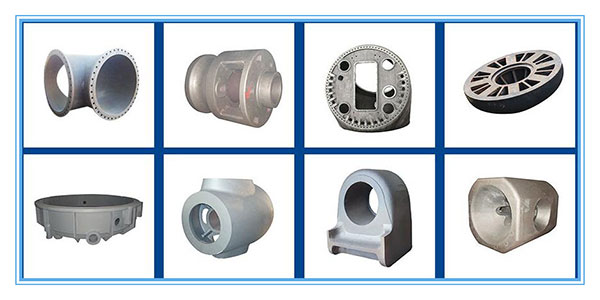

Ductile iron has better strength and ductility than gray iron. These properties allow it to be used in a wide variety of industrial usages. Because of its strength and malleability, it is most commonly used by plumbing manufacturers in pipes and pipe fittings. It is also popular in the automotive industry. Such as in engine connecting rods, cylinders.

Because it does not fracture like gray iron. Ductile iron is also safe to use in impact protection. such as bollards. Ductile iron is great for use where you need strong metal with wear resistance.

Here is a sample list of things made from or contain ductile iron:

- Pipe and pipe fittings (almost 50% of ductile iron sold in the US is for pipe and fittings)

- Axles

- Connecting rods (like in engines)

- Crankshafts

- Cylinders

- Disc brake calipers

- Gears and Gear Boxes

- Housings and manifolds

- Idler arms

- Large Machines

- Machine Tooling

- Spindle supports

- Steering knuckles

- Suspension system parts

- Truck axles

- Valves (especially high-pressure valves)

- Wheel hubs

- wheels,

- gearboxes,

- pump housings,

- Automotive components

- machine frames for the wind-power industry, and many more.

PS:

What is the difference between Ductile Iron and Cast Iron?

Cast iron refers to all iron parts that can be cast. Its carbon content is high. When Cast iron refers to gray iron. The cast parts with weaker iron structures containing graphite flakes. Ductile iron must specifically have the spherical graphite structure in the metal.

Regular cast iron or gray iron cost is cheaper. Machining is very easy. And the strength can be added by heat treating. Gray iron lacks the strength and durability of ductile cast iron. Actually, Ductile iron castings cost is not much more expensive than gray iron castings. If you want better Iron casting, ductile iron should be a good choice.

Conact us forCustom Casting Services

JC Casting Foundry works with clients from all over the world. We determine the best material for each custom casting. Request a Quote to get more information on how our casting service.JC Casting has an open capacity for new projects for both large and small castings.

We customize most of the commonly used grades of gray iron and ductile iron. If you have a request for new projects, kindly send us the drawings and specifications today. We will provide timely feedback and/or quotations.

If you are experiencing a crisis with your current supply chain or want to find a new potential supplier, Call us at +86 181 054 67890. We have the management horsepower to quickly step into the breach.