What is Duplex Stainless Steel Casting?

Duplex Stainless Steel Casting is the casting process that takes duplex stainless steel as the raw material. It is stainless steel casting which is made from a mix of 50% to 50% austenitic and ferritic phases. So it is also called austenitic-ferritic stainless steel casting. This grade casting has a high level of strength and good corrosion resistance. Especially in sea water environment applications. At the same time, these alloys also have good toughness at lower temperatures. The higher strengths provide erosion resistance.

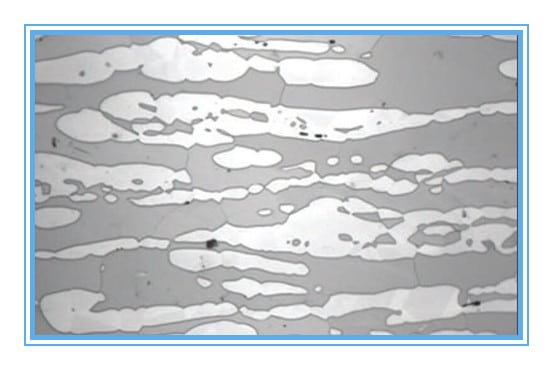

Duplex stainless steels are called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel. The picture shows that the white austenitic phase as “islands” surrounded by the grey ferritic phase. When duplex stainless steel is melted. It solidifies from the liquid phase to a completely ferritic structure. When the material cools to room temperature, about half of the ferritic grains transform to austenitic grains (“islands”). The image blowing shows a microstructure of roughly 50% austenite and 50% ferrite.

Duplex stainless steel and Super Duplex stainless steel are different.

By combining the best aspects of both ferritic and austenitic stainless steel, duplex steel get high strength and great corrosion resistance. For example, resistance to stress corrosion cracking.

Super duplex casting is more complex and more highly alloyed than duplex casting. They offer higher strength and resistance to corrosion. So they are suitable for extremely demanding usages. The Super duplex castings can meet the demands of tough environments. Such as application in desalination plants and usages in the oil and gas industries.

One of the Typical duplex stainless steel grades representatives is 2205 duplex stainless steel. Super Duplex Stainless Steel 2507 is representative of Super Duplex stainless steel.

Characters of Duplex Stainless Steel Casting

1-Strength

Duplex stainless steel casting is about twice as strong as regular austenitic or ferritic stainless steel casting.

2-Toughness and ductility

Duplex stainless steel castings have better toughness and ductility than ferritic stainless steel castings. But, they do not reach the excellent performance of austenitic stainless steel castings.

3- Corrosion resistance

Different from all stainless steel, corrosion resistance is depending on the composition of the stainless steel castings. For chloride pitting and crevice corrosion resistance, their chromium, molybdenum, and nitrogen content are most important. Duplex stainless steel casting has a range of corrosion resistance. It is similar to the range for austenitic stainless steel castings. i.e.Type 304 or 316 to 6% molybdenum stainless steel castings.

4- Stress corrosion cracking resistance

Duplex stainless steel shows good stress corrosion cracking resistance. It inherited a property from the ferritic side. Under certain circumstances of chlorides, humidity, elevated temperature, Stress corrosion cracking can be a problem for standard austenitic castings. Such as 304 and 316 stainless steel castings.

5- Cost

Duplex stainless steel castings nickel and molybdenum contents are lower than their austenitic counterparts of similar corrosion resistance. Because of the lower alloying content, duplex stainless steel can be lower in cost. Especially in high alloy surcharges. Additionally, it may often be possible to reduce the section thickness of duplex stainless steel. Due to its increased yield strength compared to austenitic stainless steel. The combination can reduce the cost and weight savings compared to a solution in austenitic stainless steel.

2205 Duplex Stainless Steel

2205 Duplex Stainless Steel is a nitrogen-enhanced duplex stainless steel casting process. It is mainly used for applications requiring high strength and excellent corrosion resistance. It is combined to improve resistance to stress corrosion cracking, pitting, and crevice corrosion. Duplex 2205 Stainless Steel Castings provide nearly double corrosion resistance performance in other austenitic stainless steels.

2205 duplex stainless steel datasheet

| Composition | Content | |

| C | 0.03 | Max |

| Mn | 2 | Max |

| Si | 1 | Max |

| P | 0.03 | Max |

| S | 0.02 | Max |

| Cr | 22.0-23.0 | |

| Mo | 3.0-3.5 | |

| Ni | 4.5-6.5 | |

| N | 0.14-0.20 |

2205 duplex stainless steel castings applications:

| Food processing equipment |

| Marine Boat Equipment |

| Chemical process vessels, heat exchangers, and piping |

| Oil field piping and heat exchangers |

| Bleach washers, chip pre-steaming vessels, and pulp mill digesters |

| Glass fittings and Glass Spigot |

Stainless-Steel-Glass-Spigot-Surface-Finish-Mirror-Polishing

SS2205-Stainless-steel-glass-spigot-profile

Stainless-Steel-Glass-Spigot-Surface-Finish-Satin-Polishing

Douplex Stainless Steel Castings Foundry

We manufacture a wide range of super duplex stainless steel castings. We are specialized in the customized production of duplex stainless steel castings and OEM. Our manufacturing capability of duplex stainless steel casting weight ranges from 1g to 100kgs. The minimum wall thickness is 1.6mm.

We have a stainless steel foundry fully equipped and machining factory. They ensure the qualified finished products each time. Besides stainless steel castings manufacturing, we also offer sand molding, chemical analysis, heat treatment, CNC Machining, and many other value-added services. From samples, drawings, and customer-supplied patterns, even we can organize pattern-making and the machining of castings. Once you placed the order with us, the rest work will be done by our team.