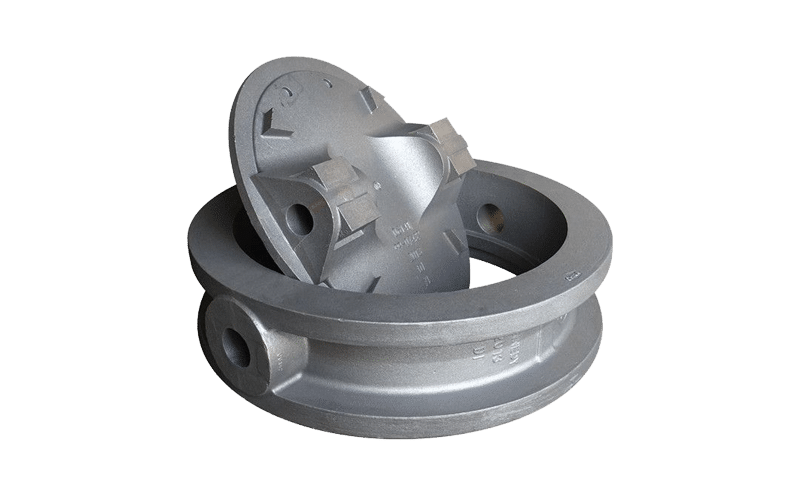

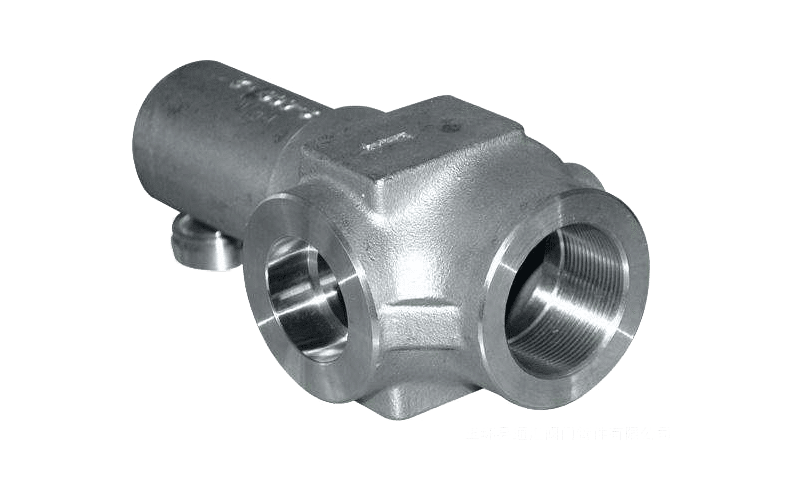

We can Supply the Best Castings for You.

Technic: Sand Casting, Wax Lost Investment Casting, Water Glass Casting, CNC Machining

Materials: Steel Casting, Iron Casting, Aluminum Casting…

Category: Medical, Aerospace, Chemical,Machinery, Construction…

About us

—— JC casting Foundry

Founded in 1997, JC Casting is a Global Investment Casting manufacturer and Supplier. We have 2 own factories and 2 partner factories in China. We focus on investment casting, sand casting, and machining technic. The raw materials range from Iron, Aluminum, Stainless Steel to Carbon Steel, Alloy Steel, and Non-ferrous alloy.

The supplying capability is also from single producing to OEM, ODM, design solution, manufacturing, inspection service. We have serviced more than 600 clients. They are from different industries, such as Construction, Machinery, Electronic, Medical, Petroleum, etc.

Featured Properties

We Can Help You

What Are You

Looking For?

Investment Casting products are used in various industries. JC Casting’s production skills and quality control are in the forefront of clients’ demand and changes!

First-class Professionals

Services

Some Feedback

What Our Clients Say

Listen to the voice of customers!

Get a supplier worth having

600+

Happy Clients

12 + years of cooperation proves that JC is a qualified supplier.

—–John Wilson

JC Casting‘s success is from their profession and services. Especially from their caring to client’s

——Wolfgang

From 10 pcs samples to today’s container order, both of us grow up together!

———Frank Schneider