Difference Between Casting mold and Die-casting mold

Mold is an important part of the investment casting process.There are different classification of Casting mold and Die-casting mold.Many friends are not aware of the difference between casting molds and die-casting molds. Even thought that there is no difference between them. In fact, there is a fundamental difference between the casting mold and the die-casting mold. We will briefly introduce this point below. Hope it is useful.

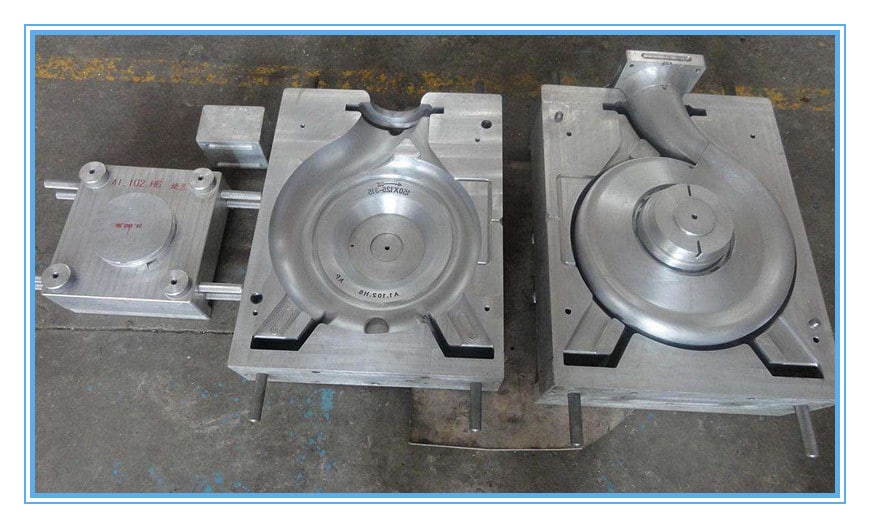

Casting mold

Casting mold: refers to the structural shape of the part in advance in order to obtain the structural shape of the part. Then the mold is placed in the sand mold, and then a cavity with the same structural size is formed in the sand mold. Further, a fluid liquid is poured into the cavity. After the liquid is cooled and solidified, a part identical to the shape of the mold can be formed.

The casting mold drives the injection head through the hydraulic cylinder to press the molten metal into the mold cavity at a high speed. Since it is oil pressure and high pressure, it is commonly called the casting mold process.

Die-casting mold

Die-casting mold: It is a method of casting liquid die forging. A process completed on a special die-casting die forging machine. Its basic process is: the metal liquid is first filled into the cavity of the mold at low speed or high speed. The mold has a movable cavity surface. It is pressed and forged with the cooling process of the molten metal, thereby eliminating the shrinkage of the blank. Loose defects also cause the internal structure of the blank to reach the forged broken grain. The overall mechanical properties of the blank are significantly improved

Die-casting molds are the three major elements of die-casting production and are indispensable. The so-called die-casting process is to combine these three elements organically. It enables the stable and rhythmic and efficient production of qualified castings. The appearance of the castings, the inherent quality, the size conforms to the drawings or the requirements of the agreement, and even more. high quality.

From the above, there are many different ways of casting mold and die-casting mold. Therefore, the choice of the mold method for users need to consider their own actual situation. Only by choosing the right way, you can get the ideal casting and save money.