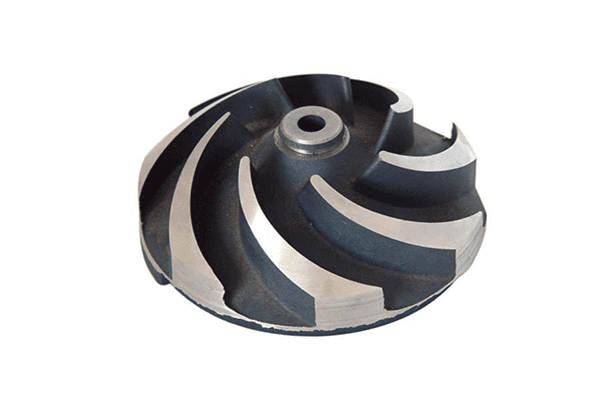

The pump impeller converts the mechanical energy into the static pressure energy and dynamic pressure energy of the conveying fluid. It is a bladed roulette. The manufacturing method of the impeller is usually casting or welding. The material can be selected according to the working environment. There are many impeller types. It can be divided according to the impeller shapes, structures and working modes.

As a pump foundry, we have produced various types of impellers. This article will explain in detail the variety of impeller types.

According to the structure

According to the impeller structure, it can be divided into channel impeller, vane impeller, spiral centrifugal impeller, and swirl impeller.

Channel impeller

The channel impeller has no blades. Also known as a bladeless impeller. There are one or two curved flow passages from the inlet of the impeller to the outlet of the impeller.

The channel-type impeller has a wide flow path and can pass through large solid particles. So, it is also very suitable for conveying fluids containing large particles of impurities or long fibers.

The flow channel impeller can be divided into single flow channel impeller and double flow channel impeller according to the number of flow channels. Among them, the double-channel impeller is well balanced and runs smoothly. Under normal circumstances, the design of sewage pumps generally adopts a double-flow impeller structure.

Advantages of channel impeller

- -The channel impeller have excellent anti-clogging performance.

- – The channel impeller also has the characteristics of good wear resistance and high efficiency.

vane impeller

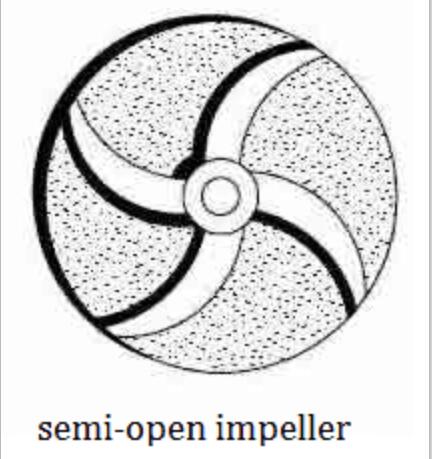

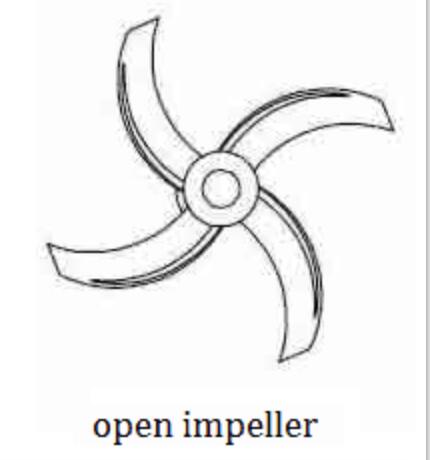

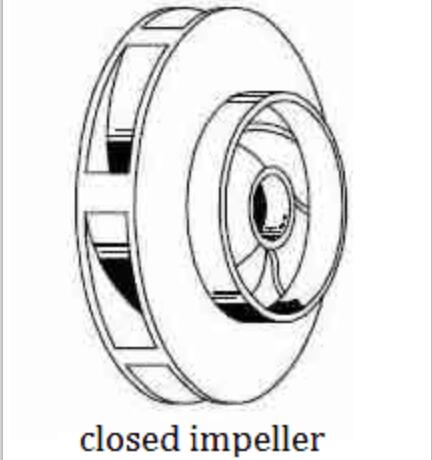

According to the impeller blades, Vane impellers can be divided into open impellers, closed impellers, and semi-open impellers.

Among them, the semi-open impeller and the open impeller are convenient to transport fluids containing solid particles. The enclosed impeller operates efficiently. It can run stably for a long time. Closed impellers are not suitable for conveying fluid media containing large particles or long fibers.

Spiral centrifugal impeller

The blades of the helical centrifugal impeller are twisted, and each impeller has 1-2 twisted helical blades. The blades of the helical centrifugal impeller extend axially from the suction port. The radius of the blade gradually increases. Form a spiral flow channel. This vane design prevents clogging with solids.

Advantages of Spiral Centrifugal Impeller

- – When the fluid flows through the blades of the helical centrifugal impeller, it will not hit any part of the pump. This will not cause any damage to the pump

- – The helical centrifugal impeller has a helical propulsion effect. The passage of suspended particles is strong.

So, the helical centrifugal impeller is suitable for conveying fluids containing large particles and long fibers.

Swirl impeller

The swirl impeller is in the shape of a disc. The leaves are evenly arranged radially. When the impeller rotates, the liquid creates a swirling motion.

Swirl impeller advantages

- -The pump with swirl impeller has good non-clogging performance. Suitable for conveying fluid media containing large particles and long fibers.

- – During the operation of the swirl impeller, suspended particles or long fibers do not come into contact with the blades. The wear on the blades is light. Long-term operation will not cause the problem of decreased efficiency.

In terms of performance, swirl impellers are less efficient. The efficiency of the swirl impeller is only 70% of that of the ordinary closed impeller.

According to leaf form

According to the blade form, it can be divided into three types: open impeller, closed impeller, and semi-open impeller.

Closed impeller

The closed impeller is the common impeller of the pump. Manufacturing is more difficult. Its structure consists of three parts: wheel disc, wheel cover and blade. Closed impellers can be used to transport liquids with relatively low viscosity. Such as water, solution, etc.

Advantages of closed impellers

- – High efficiency of closed impeller. Under the same blade type and load conditions. The efficiency of a closed impeller is higher than that of a semi-open impeller.

- -Compared with the semi-open impeller, the controllability of the rotor shaft displacement of the closed impeller is better.-The closed impeller can run smoothly for a long time.

Semi-open impeller

There are two types of semi-open impellers: front semi-open impeller and rear semi-open impeller.

The front semi-open impeller is composed of a rear cover plate and blades. The impeller of this construction is less efficient. But its efficiency can be improved by equipping the seal ring with an adjustable clearance. The rear semi-open impeller is composed of a front cover plate and blades. It has basically the same working efficiency as the closed impeller. Besides to conveying fluid, the blades of the rear semi-open impeller also have the sealing function of the back blade or the auxiliary impeller.

Unlike open impellers. The semi-open impeller is suitable for conveying fluids containing suspended solids. Such as solid particles and fibers.

Advantages of semi-open impeller

- – The semi-open impeller is less difficult to manufacture and low in cost.

- – Under the same linear velocity of the impeller, the stress of the semi-open impeller is smaller than that of the closed impeller.

Open impeller

The mechanism of the open impeller is relatively simple, and there is no cover plate. Only blades and blade stiffeners. And it has fewer leaves. Only 2-5 pieces.The working efficiency of open impeller pumps is low. few applications. It is usually used to transport liquids with higher viscosity and slurries.

The casting of open impeller and semi-open impeller is more convenient. But, due to the fluid medium conveying solid particles, the solid particles corrode the flow channel, resulting in low work efficiency. And affect the life of the impeller.

According to the working method

According to the impeller working method, The impeller is divided into single-suction impeller and double-suction impeller.

Single suction impeller

A single-suction impeller means that the impeller sucks fluid from one side. Compared with the double suction impeller, the price of the single suction impeller is cheaper.

Double suction impeller

Double suction impeller is the impeller suction liquid from both sides. The double suction impeller can transport more fluid smoothly. It has excellent anti-cavitation performance.

Although the price of the double suction impeller is high, it is still the best choice.

Impeller Foundry

JC Casting is an impeller foundry in China, we can cast various types of impellers, pump housings and other pump components. If you need it, you can contact us at any time. [email protected]