Pipe fitting is a general term for components in the piping system. Its main function is the connection, control, direction change, split, seal, and support. We are a stainless steel pipe fitting supplier and manufacturer. Our foundry specializes in producing various custom pipe fittings with our stainless steel casting and machining capabilities.

Today, we will mainly introduce Pipe Fitting types, Pipe Fitting Materials, our Manufacturing process.

Pipe Fitting types

By Processing

Steel pipe fittings are pressure pipe fittings. According to different processing methods, it is divided into four categories, namely butt welding pipe fittings (both welded and non-welded), socket welding and threaded pipe fittings, flange fittings

By Usage

- 1. The pipe fittings used for connecting pipes are: flange, union, pipe hoop, clamp, ferrule, throat hoop, etc.

- 2. Pipe fittings changing the direction of pipes: elbows and elbows

- 3. Pipe fittings for changing pipe diameter: reducer (reducer), reducer elbow, branch pipe, reinforcement pipe

- 4. Add pipe fittings of pipeline branch: tee, cross

- 5. Pipe fittings for pipeline sealing: gasket, raw material tape, thread hemp, flange blind plate, pipe plug, blind plate, head, welding plug

- 6. Pipe fittings for pipeline fixation: snap ring, drag hook, lifting ring, bracket, bracket, pipe clamp, etc.

By Materials

- 1.Cast steel pipe fittings

- 2.Cast iron pipe fittings, welding elbow

- 3.Stainless steel pipe fittings

- 4.Graphite pipe fittings

- 5.Forged steel pipe parts

Our main pipe fittings are stainless steel pipe fittings.

Stainless steel pipe fittings are one type of pipe fittings. They are made of stainless steel and are called stainless steel pipe fittings.

Main stainless steel material: 304, 304L, 316, 316L. It includes stainless steel elbow, stainless steel tee, stainless steel cross, stainless steel reducer, stainless steel cap, and so on.

- Stainless steel elbows are used for pipe turning.

- The part of the flange used to connect the pipe to the pipe is connected to the pipe end, and the stainless steel tee is used for the place where the three pipes are collected.

- Stainless steel four-way tube is used in the place where the four pipes are assembled.

- Stainless steel reducers are used where two pipes of different pipe diameters are joined.

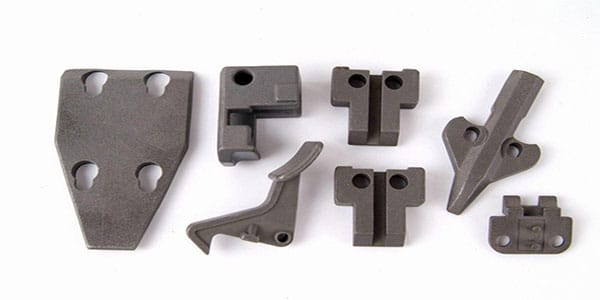

Our Pipe Fittings description

| product name | 40a 304 3r & 5r bends female threaded union rotary joint stainless steel pipe fitting |

| Material | Carbon steel ASTM A105, Stainless steel SS304/SS304L/SS316, Alloy |

| Standard | ASME, ANSI B16.11, MSS SP-79/83/95/97, JIS, B2316 |

| Pressure | Rating Threaded Fitting: 2000LB/3000LB/6000LB(Sch40, Sch80, Sch160) Socket Welding: 3000LB/ 6000LB/9000LB(Sch80, Sch160, xxs ) |

| Type | Forged Threaded Pipe Fittings(NPT/BSPT/BSPP), Socket Welded |

| Specification | Elbow, Tee, Cap , Flange, Pipe etc. |

| Size | 1/8″—4″ or customization |

| Connection | Thread, Socket welded |

| Shape | Equal, Reducing |

| Applications | Petroleum, Electric Power, Chemical Industry, Light Industry, Metallurgy, The shipping, Urban construction, and Other Professions |

Why do we choose stainless steel?

Stainless steel is one type of cast steel with a minimum of 10.5% chromium content by mass. Stainless steel casting has the features of highly corrosion-resistant and wear-resistant, provides excellent machinability, and is well-known for its shining appearance.

Our Pipe Fitting Manufacturing process

Our Pipe Fitting Manufacturing process is investment casting. The main process step as below.

- 1. Mould Preparing

- 2. Wax Model & Tree Assembly

- 3. Shell Making and Dewaxing

- 4. Casting

- 5. Cutting

- 6. Inspecting

For more process details of investment casting. Welcome, click here.

Pipe Fitting Supplier

JC casting is a Pipe Fitting Supplier in China. Besides the Main stainless steel pipe fittings, we also supply Cast Iron, Copper. Aluminum and Alloy Casting. Most pipe fittings are exported to AU,UK, Malaysia, Philippine, and so on. If you have any requests about Pipe Fitting, contact us freely.