Casting VS Machining

The production of different products is vital in industries and trades. It is then important to consider the methods of manufacturing to use. It is best to choose the most appropriate method to use to produce the required product. For metals and plastics, manufacturers have methods like casting and machining. Both manufacturing procedures are important and purposeful. But what makes them different from one another? Let this article introduce the concepts of casting and machining.

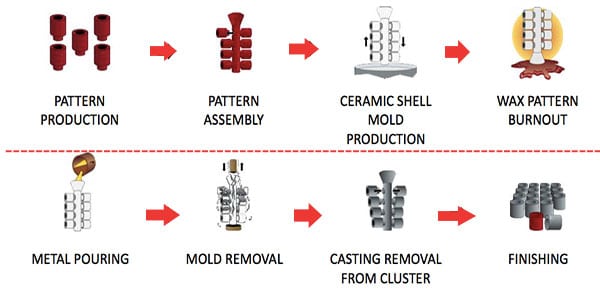

Casting

Casting or more known as cast molding involves making a tool into a required shape and form. This requires pouring molten material into the mold and allow it to solidify. Then comes the removal of the solidified material. Performing finishing procedures will follow to create the required product. Casting relies on the highs and lows of temperature as it needs to melt the material to pour into the cavity. Even from way back, industries are already using casting. They consider this a reliable manufacturing method for many industries and trades.

Machining

Modernization is never far from manufacturing. Machining is producing a product with the use of high-precision machines. It is faster, easier, accurate but more costly. There are already a lot of industries that rely on this manufacturing process. It is because it shows to be a more improved way to produce products. The machines are usually controlled by programs and software. These prompt the tools and machines to perform the process.

Both manufacturing methods produce the required outputs. But of course, there will always be similarities and differences. Here are a few comparisons between the two.

4 points of Casting VS Machining

Cost

For manufacturers and industries, the cost is one of the important factors to consider. It is easy to say that machining is costlier because it uses modern machines and tools. But different factors affect the cost of manufacturing. When checking on the cost, you may have to look at the price of the material, tools to use, and production volume. There are calculations needed to get the cost. But most of the time, the manufacturers know which method will cost more. This depends on the product that they produce.

Lead Times

If a customer or industry needs a product in bulk or a rush, then the lead times will matter a lot. Products produced using the machining method are faster and in big quantities. Machining can provide better lead times. This is when compared to the casting method of manufacturing.

Material Varieties

To produce a lot of products, the method should be able to use different materials. Both methods can use different materials for production. Machining and casting can use many different materials. Among these are metals, iron, aluminum, steel, and many others. Both of these manufacturing methods are versatile and flexible. This is why both can process different materials to produce products and components.

Quality

The quality of the product will rely on the properties that it has obtained during the process. Machining products have a better finish and a smoother texture. But casting products have a more solid composition. There are so many properties to consider when checking the quality of the products.

Both machining and casting processes are useful. Also, both can produce the products needed by industries and trades. They also create the best quality of products with the right properties. This allows the products to perform their roles well. Today, machining and casting are being used in many industries. It is because there are products that need the procedures done in casting. But some should go through machining. In the world of manufacturing, both processes are vital and efficient.

Casting and Machining are Complementary processes to each other in investment casting. Once the precision of investment casting can not fulfill the finished component requirement. Machining operations will be chosen. Machining can help to achieve more precise dimensions.it also can make the surface finish better.

JC Casting Factory

we are an investment casting foundry with 2 factories. 1 is the foundry. another 1 is the machining factory. At our foundry use last wax casting technology, Sand casting, and die casting. We can produce alloy steel casting, Stainless steel casting, carbon steel casting, Iron casting, Aluminum Investment casting, and so on. One of the benefits of the casting process is the ability to create complex shapes and internal passageways within the mold. It is are not possible for machining.

But In many cases, casting is not enough for some special shapes and dimensions. It needs machining. Many factors can determine whether the stainless steel castings will be machined. It includes casting process, complexity, and dimensional and surface finish requirements. Once the precision of stainless steel casting can not fulfill the required finished component. Machining operations will be chosen. If the tolerances for dimension and size are too tight for the casting process, the feature or hole must be machined. A nicer surface finish is important in applications when the part is meant to create a seal with another component or assembly.

Our Casing Ability

- Casting Materials Range: Stainless Steel, Steel alloy, Low Alloy Steel, Cast Aluminum, Aluminum Alloy, Carbon Steel, Super Alloy

- Technic: Was Lost Investment Casting, Sand Casting, Die Casting

- value-added services: Heat Treatment, Surface Treatment, Non-Destructive Testing Serviceb, 3D printing

Our machining factory

Machining equipment: CNC Machine. (5 sets). Lathe: (25 sets ). They are from Japan or Taiwan.3 in 1 drilling machine (10 sets). Testing equipment: Coordinate Measuring machines ( CMM )and others.

Most of our casting products are medical requirements and semiconductor equipment. On the high precision stainless steel castings machining, we have enough experience. We can handle a variety of parts, from manual turning & milling to complex multi-task CNC machining services. Our specialized turning & milling processes enable us to manufacture machined stainless steel castings with intricate geometry. At the same time maintaining high precision and accuracy. We can manufacture complex parts that require precision milling, drilling and turning.

With our foundry and machining factories, we can control the casting price well. If you look for investment casting and machining services in China. We are a good choice.