Stainless Steel Heat Treatment Process and Cautions

Stainless steel has been invented in the early 20th century for less than a hundred years. However, the situation of its development and application is extremely rapid. Especially since the late 1960s. The world’s stainless steel production has maintained an average annual growth rate of 4%. The application range of stainless steel has gradually expanded to various areas of the national economy. An important factor in the rapid development of stainless steel is its resistance to corrosion and the stainless steel heat treatment process. The advantages and disadvantages of the stainless steel heat treatment process have a great influence on the corrosion resistance and heat resistance of stainless steel. It also plays a decisive role in the processing properties of stainless steel.

Therefore, the Stainless Steel Heat Treatment Process has always been in a very important position in the production process of stainless steel.

Characteristics of Stainless Steel Heat Treatment Process

Stainless steel is a special type of steel. The Nickel and chromium content in steel is high. Due to the existence of alloying elements, such as nickel and chromium, heat treatment has the characteristics that ordinary steel heat treatment does not have.

The Stainless Steel Heat Treatment Process is to change its physical properties, mechanical properties, and residual stress. Restores corrosion resistance that is severely affected by pre-processing and heating. The aim is to get the best performance of stainless steel. Or the stainless steel can be further cold and hot processed.

The so-called heat treatment is to carry out the corresponding annealing, quenching and tempering, normalizing. It causes the like for different tissues and different types of stainless steel.

- 1. The heating temperature is higher and the heating time is relatively longer.

- 2. The thermal conductivity of stainless steel is low. The temperature uniformity is poor at low temperatures.

- 3. The austenitic stainless steel has a high-temperature expansion.

- 4. The furnace atmosphere control is very important. It can prevent the occurrence of carburizing, nitriding and decarburization, and peroxidation.

- 5. The surface gloss of stainless steel has a decisive influence on the use and price of the product. The iron oxide produced during heat treatment will seriously affect the surface gloss.

Be sure to avoid scratching the stainless steel surface and prevent deformation during heat treatment.

Different Stainless Steel Heat Treatment Process and purpose

Stainless steel types include austenite, martensite, and ferrite according to its structure. (In addition, there are precipitation hardening types, ferritic austenite types, etc.).

The heat treatment of these three types of stainless steel is different in both the treatment method and the purpose.

1. Austenitic Stainless Steel Heat Treatment Process

This type of stainless steel is the most widely used and the most used.

It is characterized by austenite structure at normal temperature and no phase change occurs. It cannot be hardened by heat treatment. But, it can be hardened by cold working.

The common Austenitic Stainless Steel Heat Treatment Process is solution treatment.

Details:

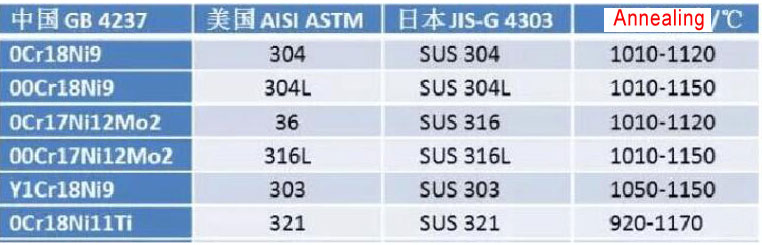

The representative steel grade for austenitic stainless steel is 18-8 steel (304). Because it is an austenitic structure, it is non-magnetic and has no hardenability. Since the steel species do not undergo a phase change, the heat treatment is to heat to a high temperature (generally above 1000 ° C). The austenite recrystallizes at the same time as the carbides produced during processing. The phase decomposed material is solid-dissolved into the austenite. Then, it is rapidly cooled to maintain the austenite in which the carbon is in a solid solution state to a normal temperature. This process is a solution treatment. Table 1 shows the reference annealing temperatures for austenitic stainless steels.

The heating temperature of the austenitic stainless steel is mainly determined by the solid solution rate of the carbide. It has been pointed out that it takes 3 minutes for the carbide of 304 steel to solidify at 1065 °C. It takes 1.5 minutes at 1176 °C and 10 minutes at 1000 °C. From this point of view, the higher the heating temperature, the better. But, the high heating temperature may cause defects such as excessive grain growth and thickening of the scale. Because austenitic stainless steel cannot refine grains by phase transformation. If the grain size is too large, the tensile strength of the material will be significantly reduced.

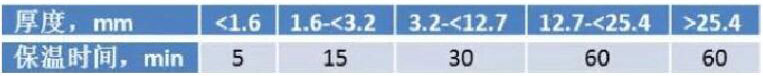

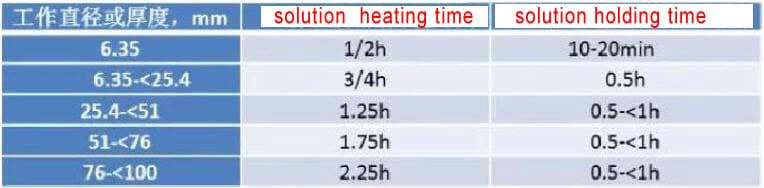

About heating time, the thermal conductivity of stainless steel is low (especially at low temperatures). After rising to high temperatures (700-800 ° C), the thermal conductivity is improved. So, for austenitic stainless steel with a large cross-section, it is necessary to preheat to 700 to 800 ° C, and then heat up quickly. For austenitic stainless steels with small cross-sections (such as strips). If the heating rate is too slow, the carbides will be analyzed and the solid solution time will be too long. The American company Amcor has developed a classic heating schedule (see Table 2, Table 3). Since chromium-based oxides formed by chromium in stainless steel are difficult to remove in pickling. The formation of chromium-based oxides is controlled during heat treatment. Stainless steel with special requirements, heat-annealing can be used.

Table 2: Austenitic stainless steel solution treatment holding time

Table 3: Austenitic stainless steel solution treatment heating time

To prevent the precipitation of solid solution carbides, the cooling rate is also important. In particular, at 600 to 700 ° C, carbides are precipitated and sensitized. So, rapid cooling must be performed. Due to the low thermal conductivity of austenitic stainless steel. The cooling of the central part is still very slow for materials with a large cross-section. No matter how fast. Sensitization is often caused by a large amount of precipitation of carbides. So, in actual production, materials with large cross-sections are generally considered to be stabilized austenitic stainless steels with elements. Such as Ti and Nb. Because elements such as Ti and Nb have a high affinity for carbon. Such stabilized austenitic stainless steels (such as 321, 347, etc.). It can be quenched without water quenching or other rapid cooling measures.

2. Ferritic Stainless Steel Heat Treatment Process

This type of stainless steel generally does not have a ν-α transition. It is a ferrite structure at high temperature and normal temperature and has no phase change. But, when the steel contains a certain amount of austenite forming elements. Such as carbon and nitrogen, an austenite structure can be formed at a high temperature.

Ferritic stainless steel cannot be strengthened by heat treatment, and can only be annealed to drop internal stress and help further processing.

Details

Ferritic stainless steel is based on chromium as the main alloying element. Its content is 12% to 30% Cr. This type of steel is a single-phase structure with no phase change and strong magnetism. Its typical representative steel grade is 430.

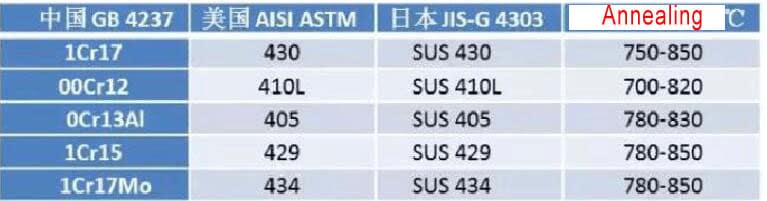

In the United States in the 1960s, cheap stainless steel 409 was developed to reduce the cost of stainless steel. Widely used in silencers and sewer pipes for automobiles and motorcycles. It is also ferritic stainless steel. This steel grade has no hardenability and cannot be hardened by heat treatment like austenitic steel. Moreover, the grain growth due to heating is faster than the austenitic steel and the grain size is large. So, grain growth and austenite transformation occur during heat treatment. The heating temperature should not be too high. The maximum heating temperature of the general annealing does not exceed 850 °C. Table 4 shows the reference annealing temperature for ferritic stainless steel.

Table 4: Reference annealing temperature of ferritic stainless steel

When annealing ferritic stainless steel, it is necessary to shorten the residence time in the temperature range of 370 to 550 °C. Especially for high chromium ferritic stainless steel. If the material stays too long in this temperature range, brittleness at 475 °C is easy to occur. That is, the hardness is increased, and the elongation is drastically reduced, even zero. At the same time, the corrosion resistance of the material is also reduced. Experiments have shown that the tensile strength of the material increases by 50% at room temperature after heating for 27 hours at 475 °C. Yield strength increased by l50%. The elongation is zero. Also, the steel grade has poor weldability (the grain in the weld heat-affected zone is coarse and brittle).

3. Martensitic Stainless Steel Heat Treatment Process

This type of stainless steel has a distinct phase change point. It is an austenite structure at high temperatures, and martensite transformation can occur during cooling. It transforms into a martensite structure and hardens.

Because of its high chromium content and good hardenability, various heat treatment methods, such as quenching and tempering, can be used.

In this paper, the heat treatment methods and characteristics of the three types of stainless steel, which are widely used, are discussed separately.

Deatils

The properties of martensitic stainless steel are significantly different from Ferritic stainless steel and Austenitic stainless steel.

As the name implies, it is transformed from a high-temperature austenite state to a cold (quenching) martensite structure. This type of stainless steel has a distinct phase change point. It can be hardened by quenching. Moreover, because of its high chromium content, good hardenability. It can adjust its strength and toughness in a wide range during tempering.

So, martensitic stainless steel can be used both for structural steel and tool steel.

When martensitic stainless steel is used as tool steel, it is quenched. For quenching, it is necessary to heat up to above the critical point. To solidify the carbide into the austenite. When the temperature is raised to solidify the carbide, the carbon diffusion rate is slow. To get a uniform austenite structure, the heat of the mouth is generally 50 ° C higher than the critical point temperature. And must also have a certain holding time. To fully and uniformly dissolve the carbide. Of course, if the heating time is too long and the heating temperature is too high, the martensite structure will be uneven. The retained austenite structure is increased, so that internal stress is generated due to poor expansion inside the material.

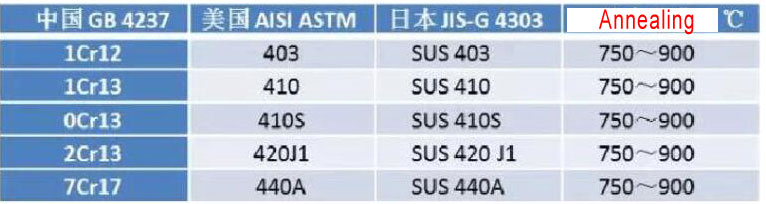

Martensite steel is a kind of hot crack-sensitive steel. The steel has a low thermal conductivity at low temperatures and is prone to cracking when heated rapidly. Thus, when processing large-section materials, they should be preheated and then rapidly heated. Table 5 shows the reference annealing temperature for martensitic stainless steel.

Table 5: Reference annealing temperature of martensitic stainless steel

When used as structural steel, it should be tempered (tempered state) based on quenching. Martensitic stainless steel has temper brittleness. The tempering temperature should generally not be lower than 580 °C. When cooling from the tempering temperature, oil cooling is generally used to avoid temper brittleness. Air cooling may also be used to get a higher yield limit. But, an important mechanical indicator of structural steel will have a lower impact value. It should be noted that the martensitic stainless steel should be tempered as soon as possible after quenching. If it cannot be tempered as soon as possible, the material is prone to cracks.

4. Precipitation hardening Stainless Steel Heat Treatment Process

Although austenitic, ferritic, and martensitic stainless steels are widely used, as structural steels. There are still some insurmountable defects. Austenitic stainless steel has a lower yield strength. Only about 200N/mm2. Not suitable for use as structural steel. Although the martensitic stainless steel can get a high yield strength by heat treatment such as quenching or tempering. But, its corrosion resistance is poor.

For applications requiring the most corrosion resistance and greatest strength, a new type of Cr-Ni stainless steel was developed. Precipitation hardened stainless steel (also known as PH stainless steel) has been developed.

Details

The heat treatment of this new type of stainless steel includes homogenization, full annealing, solution heat treatment, aging treatment, and transformation cooling. Its characteristics are:

- 1. The fully annealed state is soft and easy to reprocess.

- 2. The required mechanical properties can be obtained by appropriate aging treatment.

- 3. It has the same corrosion resistance as similar stainless steel. Improved performance against stress corrosion cracking.

- 4. Transition cooling is suitable for cooling below a certain temperature.

A commonly used precipitation hardening type of stainless steel is a martensite type, and its representative steel type is 631 (0Crl7Ni7A1). The heat treatment of the steel is first carried out by solution treatment. After the material is heated to 1000 ~ 1100 ° C, it is quickly cooled. Then, according to different mechanical properties, aging treatment is carried out at different temperatures. Such as 621 ° C, 565 ° C, 510 ° C aging.

Conclusion

The above analysis showing the Stainless Steel Heat Treatment Process is more complicated. Different heat treatment methods should be adopted according to the characteristics of different steel grades. This will meet the different requirements of users.

JC Casting is a China stainless steel casting manufacturer and supplier. We cast different types of stainless steel precision castings with different Stainless Steel Heat Treatment processes. And our engineers will confirm your end using of your products before we start producing. If you have any new inquiries, contact us today to get a prompt reply within 12 hours.