CF8 VS CF8M STAINLESS STEEL FAQ

CF8M vs CF8 Stainless Steel Casting

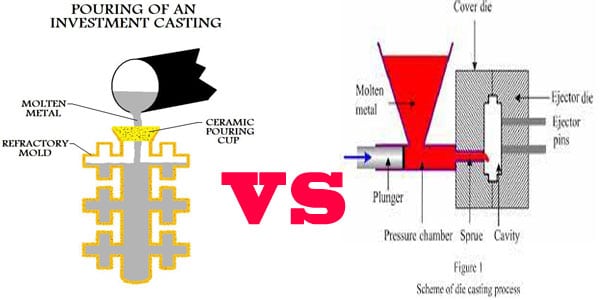

CF8 stainless steel and CF8M stainless steel are the common cast stainless steel grades in investment casting foundries. They are similar, but not complete the same. JC Casting Foundry focuses on the stainless steel casting method for more than 20yrs, we normally cast CF8 and CF8M stainless steel casting for many application industries.

This time, we will help you to understand the differences between these two alloys and casting. How to choose a suited alloy for your design.

CF8 Stainless Steel Casting

AISI 304 or CF8 stainless steel castings means the casting parts made of CF8 stainless steel. It is a general grade, belonging to austenitic stainless steel. It is widely used in the foundry industry. The standard composition of CF8 stainless steel is 18% chromium plus 8% nickel. It is non-magnetic. When the impurity content is high, it will occasionally show weak magnetism after processing. This weak magnetism can only be eliminated by heat treatment. It belongs to stainless steel whose metallographic structure cannot be changed by heat treatment.

In the international standard, the grades equivalent to CF8 stainless steel are: 1.4301, X5CrNi18-10, S30400, CF8 and 06Cr19Ni10. As one of the most widely-used materials of stainless steel, CF8 stainless steel castings play an important role in serving our customers.

CF8 is the equivalent investment cast alloy of AISI 304 stainless steel. It belongs to austenitic stainless steel that presents good strength and ductility. As the chemical composition of CF8 includes approximately 18% chromium and 8% nickel by weight, it is also known as 18/8 stainless steel.

For its good cavitation resistance, CF8 is the primary choice to cast stainless steel components. Such as pump impellers, some important parts for water handling application. It also provides strong oxidation resistance and corrosion resistance, especially in some special media. Such as hydrocarbons, liquid oxygen, organic liquids, nitric acid, sodium carbonate. So it is also an ideal cast alloy to produce some parts like stainless steel valves fittings, stainless steel flanges, stainless steel mixing agitators and propellers, stainless steel spray nozzles.

CF8M Stainless Steel Casting

The usual heat treatment for CF8M is solid Solution by heating to more than 1900 °F (1040 °C), holding for enough time. Then quenching in water or rapid cool by other means.

CF8M is an upgraded austenitic stainless steel alloy of CF8. It contains a molybdenum element. The equivalent cast stainless steel alloy is AISI 316 stainless steel. Compared to CF8 stainless steel, The presence of molybdenum in CF8M increases the corrosion resistance and the resistance to pitting by chlorides.

CF8M stainless steel is the proper alloy to cast stainless steel parts. It requires excellent corrosion resistance that CF8 can not provide. It can be used to produce parts including stainless steel valve components, marine boat hardware, impellers, propellers, pump casings, valve bodies and press plates, other pressure-containing parts, food machinery parts.

CF8 and CF8M Stainless Steel Casting Foundry

CF8M stainless steel castings show better corrosion resistance. But CF8 stainless steel castings have a lower cost. The selection of these two alloys mainly depends on the working environment. If you are unfamiliar with them, JC Casting can recommend a good alloy for your cast stainless steel product according to our rich casting experience.

When JC casting foundry was created in China, the company’s most the production of high-quality stainless steel castings mainly in ASTM CF8, CF8M stainless steel alloys using an investment casting process. These two alloys take up most of the stainless steel castings output of our stainless steel foundry. Besides we can also cast stainless steel in other alloys like CF3, CF3M, CG8M.

Our company has an ISO9001:2015 certificate. All the castings can be supplied in finish machined status. And all pars will be tested before delivery to suit our customers’ requirements. Any inquiry on CF8 or CF8M stainless steel casting, pls feel free to contact our foundry! Email: [email protected]