Gray Iron Casting VS Ductile Iron Casting

The casting industry has become bigger and better these days. There are now a lot of casting manufacturers and suppliers around. This proves that this industry is a big help to the different industries and trades.

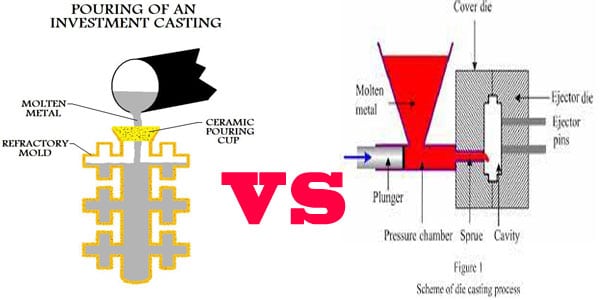

Casting iron derives from melting metal materials. The process involves pouring the molten metal into a mold to create the desired end product. This procedure is important in manufacturing. With this, industries can get the components needed for their operations and services.

There are many different iron castings available for use. Two of these are gray iron casting and ductile iron casting. Though both castings are useful, there is still some confusion on which one to choose. So, what are the differences between the two? Read on.

Gray Iron Casting

Gray iron casting forms with the flake shape of the graphite molecules found in the metal. The gray color comes from the fracture in the metal. The break that comes along the graphite flakes gives off that gray color.

This type of casting has great properties to offer. It has high levels of compressive strength. It is also good in deformation resistance, tensile strength, and oxidation resistance. It also has a low melting point.

Common Applications

There are lots of applications and uses that people can get from gray iron casting. Different industries rely on it in getting the components needed for their operations. The common applications and uses of gray iron casting include:

- Machinery Bases

- Gears

- Automotive parts and equipment

- Stove parts

- Tractor parts

- Wind turbine housings

- Weights

- Counterweights

- Pumps

There are lots of industries that enjoy gray iron casting. It is able to create different components and products important for many industries. Gray iron casting has different grades to specify the properties that it will have.

Common Gray Iron Grades

- Class 25

- Class 30

- Class 35

- Class 40

Class 25 is the most used gray cast iron. It offers exceptional machinability, heat resistance, and corrosion resistance.

Choosing Class 30 is imperative when the product needs to be strong. It can also provide wear-resistant end products that can withstand high temperatures.

The other grades are rarely used but there are still some products that may need the use of these grades.

Ductile Iron Casting

Ductile iron casting shows round graphite structures found in the metal. It is also known as nodular cast iron. The ductile iron casting comes from molten iron added with carbon. The iron-carbon combination makes this casting efficient against fatigue and wear.

Ductile iron casting is a preferred type of casting because of its great properties. It has good hardness and tensile strength. Ductile iron also has high compressive strength, fatigue strength. It is corrosion-resistant and good at withstanding impact. These properties make it a popular casting as it shows reliability.

Common Applications

- Agricultural tractors

- Oil well pumps

- Diesel trucks

- Machine frames

- Automotive components

- Pump housings

- Gearboxes

- Wheels

Industries relying on ductile iron casting enjoy the different properties that it possesses. It is effective in providing industries the components they need to operate and well.

Common Ductile Iron Grades

- Grade 60-40-18

- Grade 65-45-12

- Grade 80-55-06

- Grade 100-70-03

- Grade 120-90-02

The grades of the ductile iron casting will determine the strength the material has. The choice of grade to use should depend on the properties needed by the product.

Gray Iron Casting VS Ductile Iron Casting

Gray iron casting and ductile iron casting are both useful. They are efficient materials for industries and trades. Manufacturers use them in creating components that will provide purpose for industry operations. But, the choice between the two castings will rely on the type of product needed. There are also properties where the two have similarities and differences. Knowing these will help one know which casting to choose and use.

Ductility

Ductility is the ability of the material to expand or stretch without getting broken. Ductile iron casting has a better ductility level than gray iron casting. Adding magnesium to ductile iron makes it stronger and can withstand extreme tension.

Tension Strength

Ductile iron casting has better tensile strength. It can withstand extreme tension and pressure. Gray iron casting also has the ability to endure tension. But its level is still inferior as compared to ductile iron casting.

Impact Strength

Ductile iron castings can endure a greater impact. This makes its impact stronger than the gray iron casting. It can resist at least seven-foot pounds of impact.

Vibration Reduction

Gray iron casting can reduce vibration more than ductile iron casting.

Thermal Conductivity

Gray iron casting has better thermal conductivity than ductile iron casting.

Applications

Gray iron casting focuses on more non-critical applications. This is because it is lesser in strength. With ductile iron casting, it can do engineered applications due to its strength.

Cost

Gray iron casting is cheaper than ductile iron casting. But when it comes to producing strong and ductile products, the price is no longer considered.

Despite all the comparisons, both castings are efficient for many industries. With these castings, industries have an easier time getting the components they need. The best thing about these castings is that they have great properties. These are all perfect for the types of products needed in the industries.

Choosing the type of casting to use is not easy. It takes an expert to know the best casting to choose. It is a good thing that there are a lot of companies offering casting products and services. This will help one get the right casting to use. It is best to know the reputable and reliable companies to deal with. This way, it will be easy to get the utmost quality of products and services.

Conclusion

Gray iron casting and ductile iron casting are two of the casting types. Both castings are efficient, and reliable in producing the needed products and components. But learning more about Gray iron casting vs ductile iron casting differences, uses and properties are important. It will help one know which casting to choose and use. Getting help from experts and casting manufacturers and suppliers is a good idea. With this, one will get the best advice on the type of casting to use. They will also learn the perfect casting that the component needs.